Preparation method of an in-situ carbon-doped hollow titania visible light catalyst

A titanium dioxide and catalyst technology, applied in the field of titanium dioxide photocatalyst, can solve the problems of poor ability to utilize solar energy, low partial utilization of visible light, and low quantization yield, and achieve low cost, high-efficiency visible light catalytic activity, and strong resistance to light corrosion effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

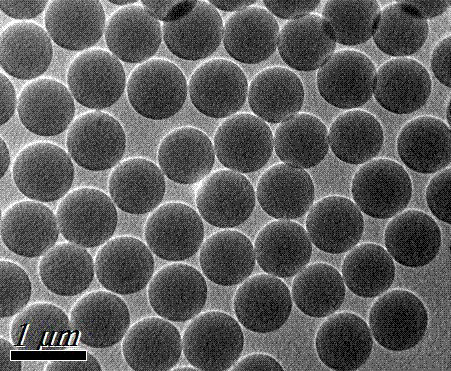

[0047] Put 72g of deionized water, 8g of styrene and 0.16g of potassium persulfate into a 150ml four-necked bottle, and remove the air with nitrogen at a stirring speed of 350rpm. After about 20 minutes, use the pre-adjusted approx. Warm water at 70°C was quickly poured into a constant temperature water bath, and kept at 70°C; after 1.5 hours of reaction, under the protection of nitrogen, a mixture of 1.2 g of VTC and deionized water (mixed with deionized water Volume ratio 1:1) into the reaction bottle, the first three injections every half an hour (10μl per injection), and then two injections, one injection every hour, each injection is (50μl); then the remaining solution was injected every 3 Inject one injection per minute, each injection is (10µl), until all the remaining VTC is injected. After the injection is completed, extend the polymerization for about 12 hours to make it fully polymerized. After the polymerization is completed, use a water-based microporous membrane ...

Embodiment 2

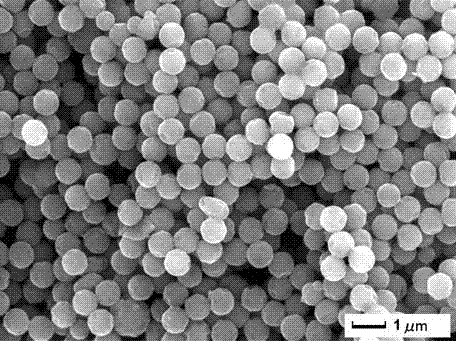

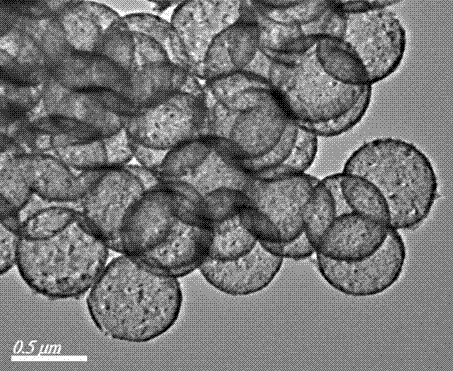

[0049] Preparation of carbon-doped hollow titanium dioxide microspheres with a shell thickness of about 20 nm: Add 4 g of PS template and 40 mL of ethanol in a 100 mL three-necked flask, stir evenly with magnetic force, and control the temperature of the reaction system at 0 ℃, slowly add 20 mL of prepared 0.1 g / mL n-tetrabutyl titanate ethanol solution to the reaction system dropwise, after settling for 24 hours, slowly add 3 mL of deionized water and 6 mL of ethanol dropwise (the amount of water should not be too much High, otherwise the TBT hydrolysis rate is too fast) After the liquid is combined, the hydrolysis reaction is carried out for 20 hours; after the reaction is completed, the sample is centrifuged, washed with deionized water and ethanol alternately several times, and dried in an oven at 60 °C for 15 hours to obtain polystyrene-titanium dioxide Core-shell structure; carbon-doped hollow titanium dioxide microspheres are prepared by performing a specific segmented t...

Embodiment 3

[0051] Preparation of carbon-doped hollow titanium dioxide microspheres with a shell thickness of about 29 nm: Add 4 g of PS template and 40 mL of ethanol in a 100 mL three-necked flask, stir evenly with magnetic force, and control the temperature of the reaction system at 0 ℃, slowly drop the prepared 20 mL, 0.15 g / mL n-tetrabutyl titanate ethanol solution into the reaction system, after settling for 24 hours, slowly add a mixture of 3 mL deionized water and 6 mL ethanol for hydrolysis reaction After the reaction was completed, the sample was centrifuged, washed several times with deionized water and ethanol alternately, and dried in an oven at 60 °C for 15 h to obtain a polystyrene-titanium dioxide core-shell structure; The carbon-doped hollow titanium dioxide microspheres are prepared by segmental temperature programming and calcination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com