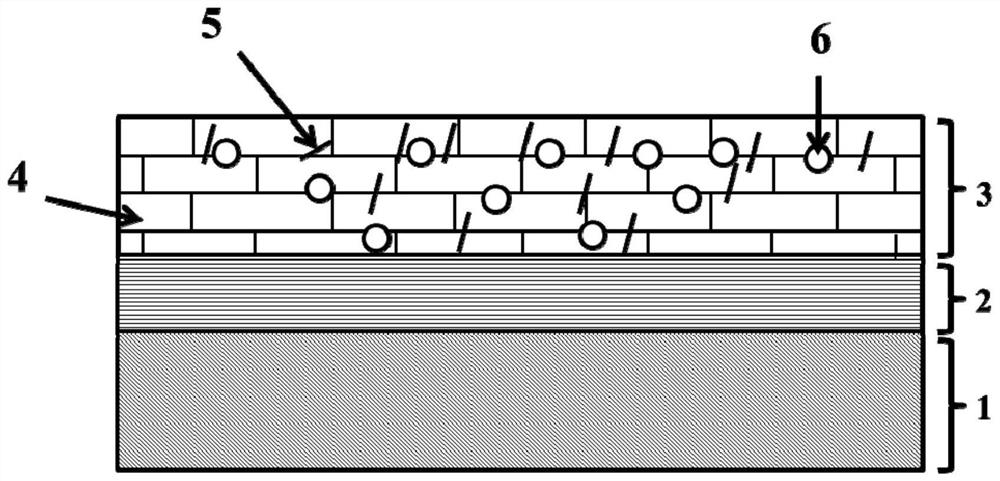

A material and method for porosity regulation and strength supplementation of thermal barrier coatings

A technology of thermal barrier coating and porosity, applied in coating, metal material coating process, fusion spraying, etc., can solve problems such as failure, thermal barrier coating peeling, etc., and achieve the effect of improving melting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

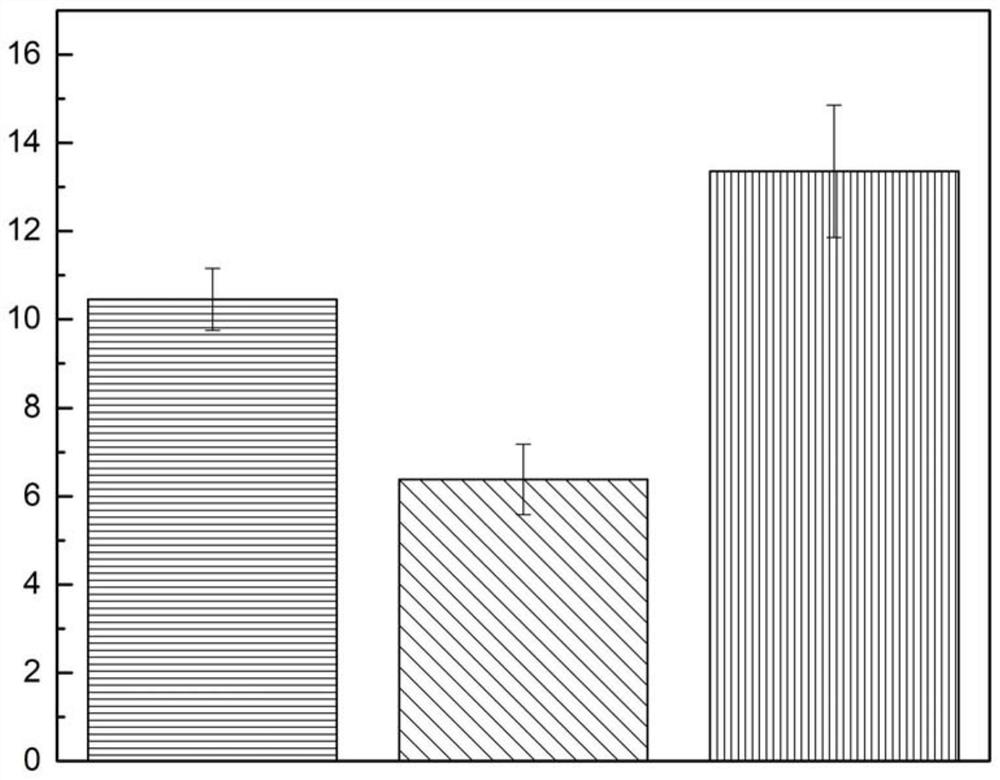

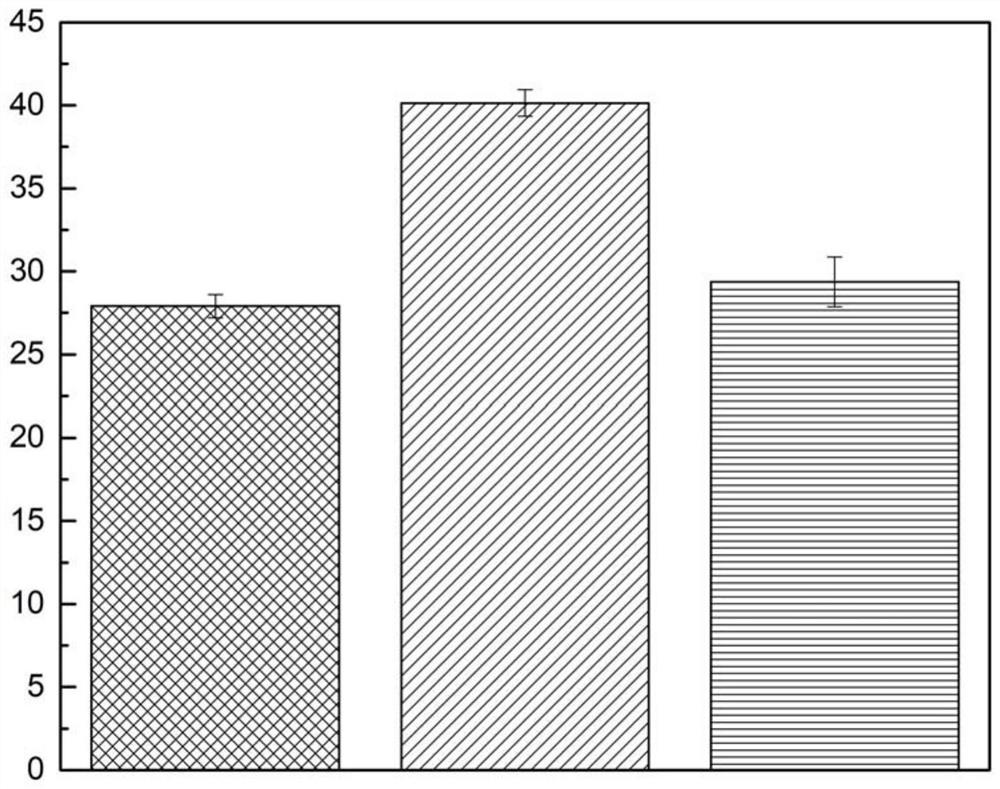

Examples

Embodiment 1

[0058] 1. Containing 5% La by mass fraction 2 o 3 Preparation of YSZ pore-inhibiting powder for pore-inhibiting modified phase: firstly, La 2 o 3 and YSZ original powder were air-dried separately, the drying temperature was 900 ° C, and the drying time was 1 h; secondly, the La 2 o 3 Powder, YSZ powder, 15% trimethylamine aqueous solution dispersant, and ceramic balls were added to the ball mill tank according to the mass ratio for suspension adsorption mixing. The powder is washed and filtered; finally, the pore suppressing powder is sprayed and granulated at an inlet temperature of 360°C and an outlet temperature of 125°C, and the particle size of the final product is 20 μm-160 μm.

[0059] 2. Preparation of YSZ toughened pore-forming powder containing 8% SiC fiber toughened and pore-forming modified phase by mass fraction: First, carry out stirring, purification and dispersion, and use hydrofluoric acid and polyglycol at a mass ratio of 1:1 to purify the dispersion, 10...

Embodiment 2

[0067] 1. Containing a mass fraction of 4% La 2 o 3 with 4% CeO 2 Preparation of YSZ pore-inhibiting powder for pore-inhibiting modified phase: firstly, La 2 o 3 , CeO 2 and YSZ original powder were air-dried separately, the drying temperature was 900 ° C, and the drying time was 1 h; secondly, the La 2 o 3 Powder, CeO 2 Powder YSZ powder, 15% trimethylamine aqueous solution dispersant, and ceramic balls are added to the ball mill tank according to the mass ratio for suspension adsorption mixing. Perform washing and suction filtration; finally, spray and granulate the pore-suppressing powder under the condition that the inlet temperature is 360°C and the outlet temperature is 125°C, and the particle size of the final product is 20μm-160μm.

[0068] 2. Preparation of YSZ pore-forming powder containing 8% YSZ fiber toughened pore-forming modified phase by mass fraction: First, carry out stirring, purification and dispersion, and use hydrofluoric acid and polyglycol with a...

Embodiment 3

[0073] 1. Containing 5% La by mass fraction 2 o 3 BaLn 2 Ti 3 o 10 (BLT) anti-pore powder preparation: first, La 2 o 3 and BLT raw powder were blast-dried separately, the drying temperature was 900°C, and the drying time was 1h; secondly, La 2 o 3 Powder, BLT powder, 15% trimethylamine aqueous solution dispersant, and ceramic balls were added to the ball mill tank according to the mass ratio for suspension adsorption mixing. The powder is washed and filtered; finally, the pore suppressing powder is sprayed and granulated at an inlet temperature of 360°C and an outlet temperature of 125°C, and the particle size of the final product is 20 μm-160 μm.

[0074] 2. Preparation of BLT pore-forming powder containing 4% SiC fiber and 4% YSZ fiber toughened pore-forming modified phase by mass fraction: first, carry out stirring, purification and dispersion, and use hydrofluoric acid and polyglycol at a mass ratio of 1:1 for purification Dispersion liquid, 100r / min magnetic stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com