Hydrogen gas fire arrester

A flame arrester and hydrogen technology, applied in fire rescue and other directions, can solve the problems of unreliable flame arrester, easy burning and melting failure, etc., to avoid burning or failure, effective and reliable fire resistance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

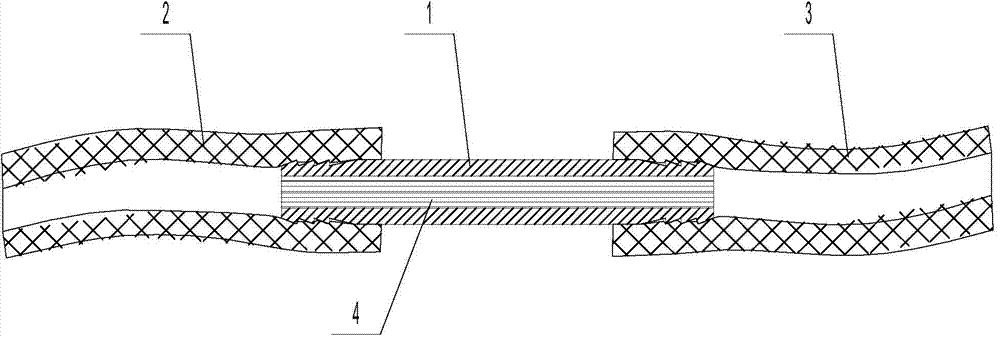

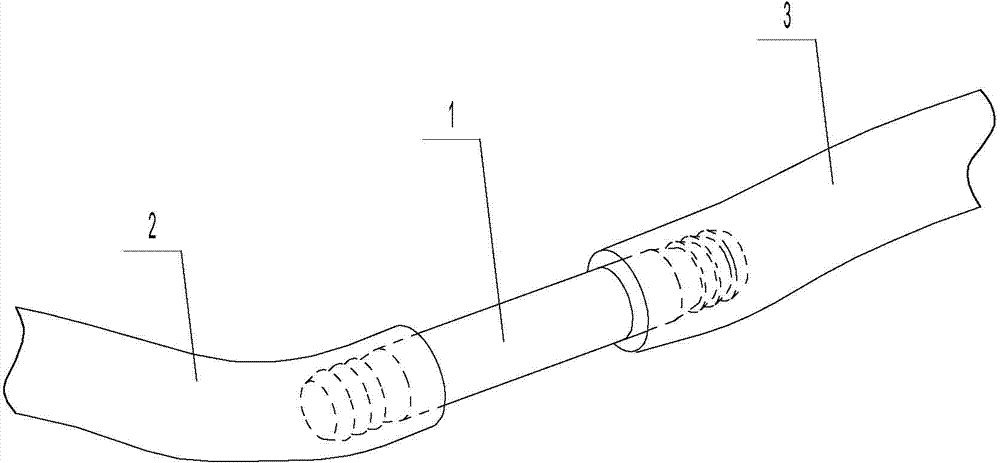

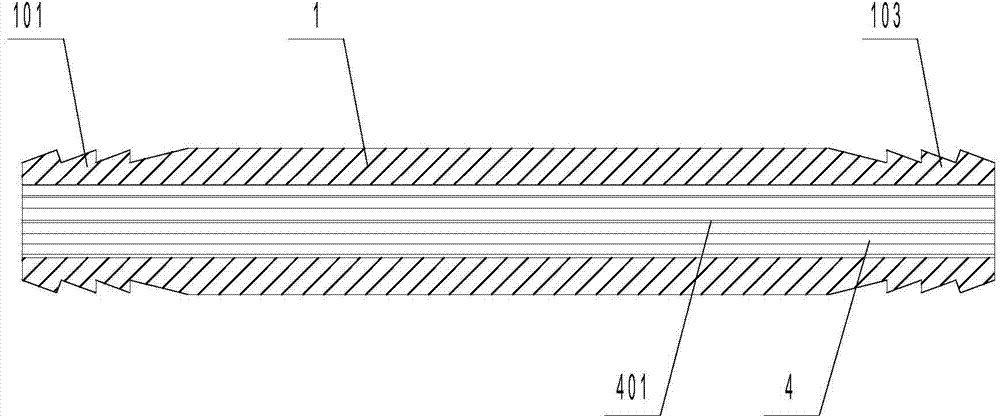

[0032] Figure 1-Figure 2 Disclosed in is a hydrogen flame arrester, including a flame arrester sleeve 1, one end of the flame arrester sleeve 1 is an air inlet joint 101 connected to an intake pipe 2, and the other end is an outlet joint 103 connected to an air outlet pipe 3, and the flame arrester sleeve A fire arrester 4 is installed inside the tube 1; the fire arrester 4 is a large number of thin metal wires, which are filled in the flame arrester casing 1 in a regular and orderly manner along the radial direction, forming a large number of regularly arranged The elongated gas guide micropore 401; the end of the flame arrester 4 is flush with the end face of the gas outlet joint 103 (see Figure 3-Figure 5 ). The air outlet pipe 3 is a non-metallic pipe.

Embodiment 2

[0034] A hydrogen flame arrester, the structure of the flame arrester is basically the same as that of Embodiment 1, the difference is that a radiator 5 is provided outside the flame arrester casing 1 .

[0035] The specific structure of the hydrogen flame arrester described in the second embodiment is as follows:

[0036] A hydrogen flame arrester, comprising a flame arrester sleeve 1, one end of the flame arrester sleeve 1 is an air inlet joint 101 connected to an intake pipe 2, and the other end is an outlet joint 103 connected to an air outlet pipe 3, and the flame arrester sleeve 1 is installed There is a fire arrester 4; the fire arrester 4 is a large number of fine metal wires, which are filled in the flame arrester casing 1 in a regular and orderly manner along the radial direction, forming a large number of regularly arranged elongated The air guide microhole 401; the end of the fire arrester 4 is flush with the end face of the air outlet joint 103; the outlet pipe 3 ...

Embodiment 3

[0038] A hydrogen flame arrester, the structure of the flame arrester is basically the same as the second embodiment, the difference is that: the flame arrester casing 1 is also equipped with a temperature sensor 6, and the air inlet pipe 2 is also installed with a The detection data of the temperature sensor automatically cuts off the solenoid valve 7 of the air source (for the electrical schematic diagram, see Figure 9 ).

[0039] The specific structure of the hydrogen flame arrester described in the third embodiment is as follows:

[0040] A hydrogen flame arrester, comprising a flame arrester sleeve 1, one end of the flame arrester sleeve 1 is an air inlet joint 101 connected to an intake pipe 2, and the other end is an outlet joint 103 connected to an air outlet pipe 3, and the flame arrester sleeve 1 is installed There is a fire arrester 4; the fire arrester 4 is a large number of fine metal wires, which are filled in the flame arrester casing 1 in a regular and orderl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com