Connected two-way pressure stabilizing water seal device and operation method

A technology of water sealing device and bidirectional voltage stabilization, applied in the directions of packaging, transportation and packaging, large containers, etc., can solve problems such as increased electrical loss, explosion accidents, waste of water resources, etc., to avoid liquid loss and prevent fire hazards. , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

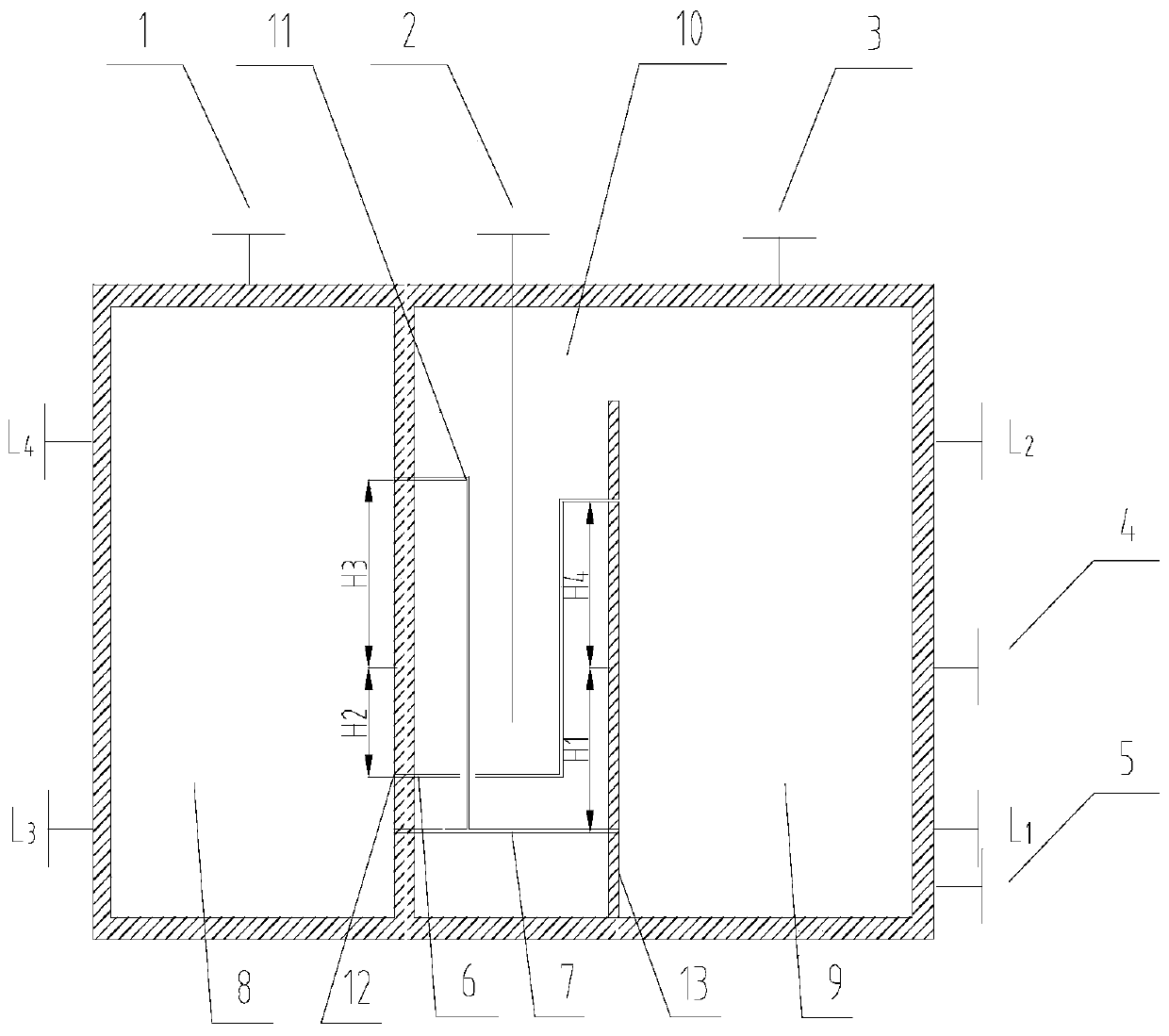

[0024] The connected two-way pressure stabilizing water seal device includes a built-in liquid storage chamber partition 12 and a transition chamber partition 13 to divide it into a left liquid storage chamber 8, a transition chamber 10 and a right liquid storage chamber 9, A liquid level gauge port L4 is provided on the outer upper part of the left liquid storage chamber 8, a liquid level gauge port L3 is provided on the outer lower part, an atmospheric vent 1 is provided on the upper part of the left liquid storage chamber 8, and the transition chamber 10 The upper part is provided with a gas inlet 2, the upper part of the right liquid storage chamber 9 is provided with a liquid inlet 3, and the upper part of the right liquid storage chamber 9 is provided with a liquid level gauge port L2 at the same height as the liquid level gauge port L4, and the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com