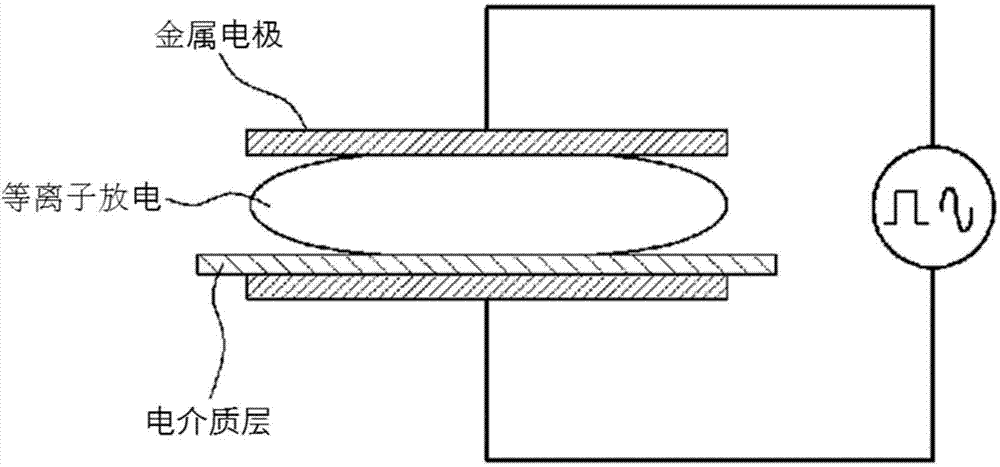

Dielectric barrier discharge-type electrode structure for generating plasma having conductive body protrusion on electrodes

A technology of dielectric barrier discharge and electrode structure, which is applied in the installation/support/configuration/insulation of plasma, corona discharge devices, electrode assemblies, etc. problem, to achieve excellent plasma efficiency, excellent power consumption, and low air back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0145] To evaluate the performance of the plasma electrode structure, an air cleaner module consisting of a fluid inlet, a plasma electrode, and a fluid outlet was used. The energized electrode is made of stainless steel 403 and has a circular plate shape with a diameter of 50mm and a thickness of 1mm. Using a stamping method, five are distributed on the outer profile of the diameter of the plate at a consistent angle, with a height of 50μm. The electrode protrusions are formed again in the same way at the central part of the radius to make 5 protrusions. In addition, 48 circular through-holes with a diameter of 3.6mm are evenly distributed on the board. Its open area is 25% of the total area. After that, aluminum oxide and barium titanate powder with a particle size of 1-2um are used as dielectric components, and polyvinylidene fluoride (PVDF, Polyvinylidene fluoride) as a polymer is used as a binder, through a typical spraying (spray) process , form a dielectric layer with...

Embodiment 2

[0149] The electrical energy applied to the electrodes is measured, i.e., the number of anions generated as the pulse width increases, and at Figure 13 is shown in . Such as Figure 13 As shown, it can be known that the number of anions generated increases at an extremely fast rate with the increase of the pulse width, and when the pulse width is close to 100 μs, the number of anions per cubic centimeter is close to 1 million.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com