Method for preparing porous germanium by utilizing electrodeposition of ionic liquid

An ionic liquid and electrodeposition technology, which is applied in electrode manufacturing, electrochemical treatment of electrodes, circuits, etc., can solve problems such as small volume expansion of voids, prevent shedding and loss, improve utilization rate, and improve charge and discharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

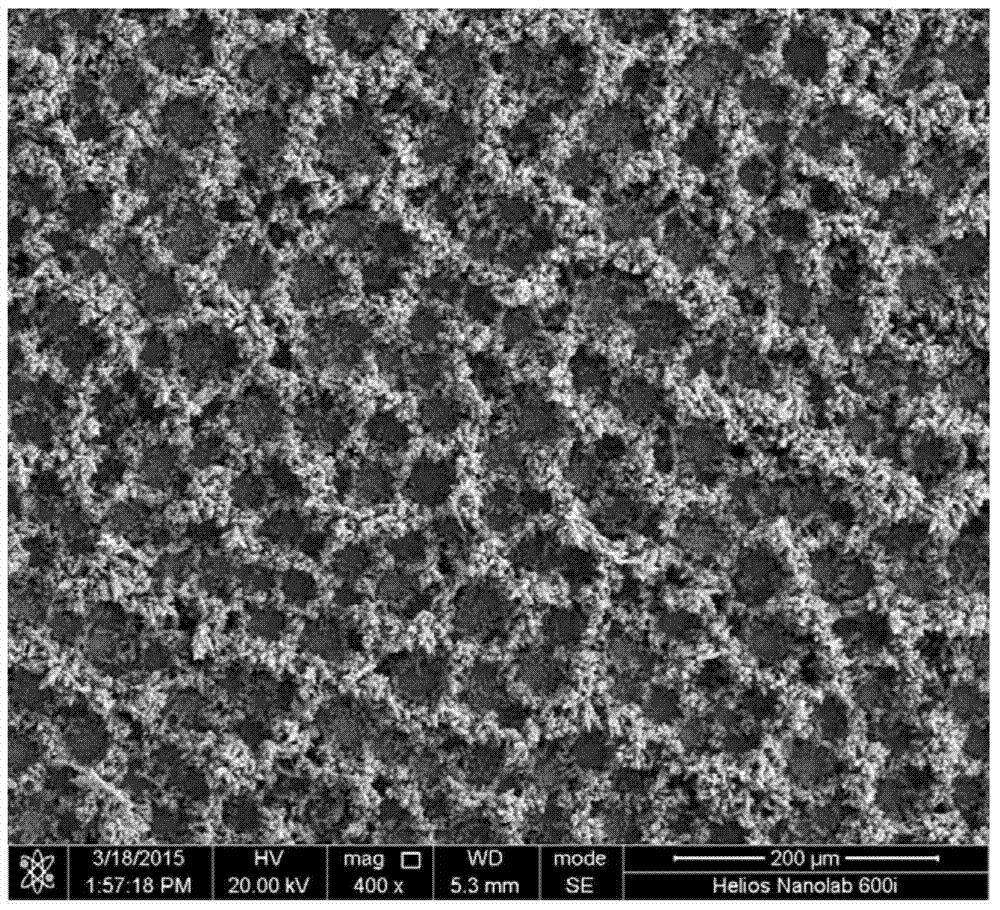

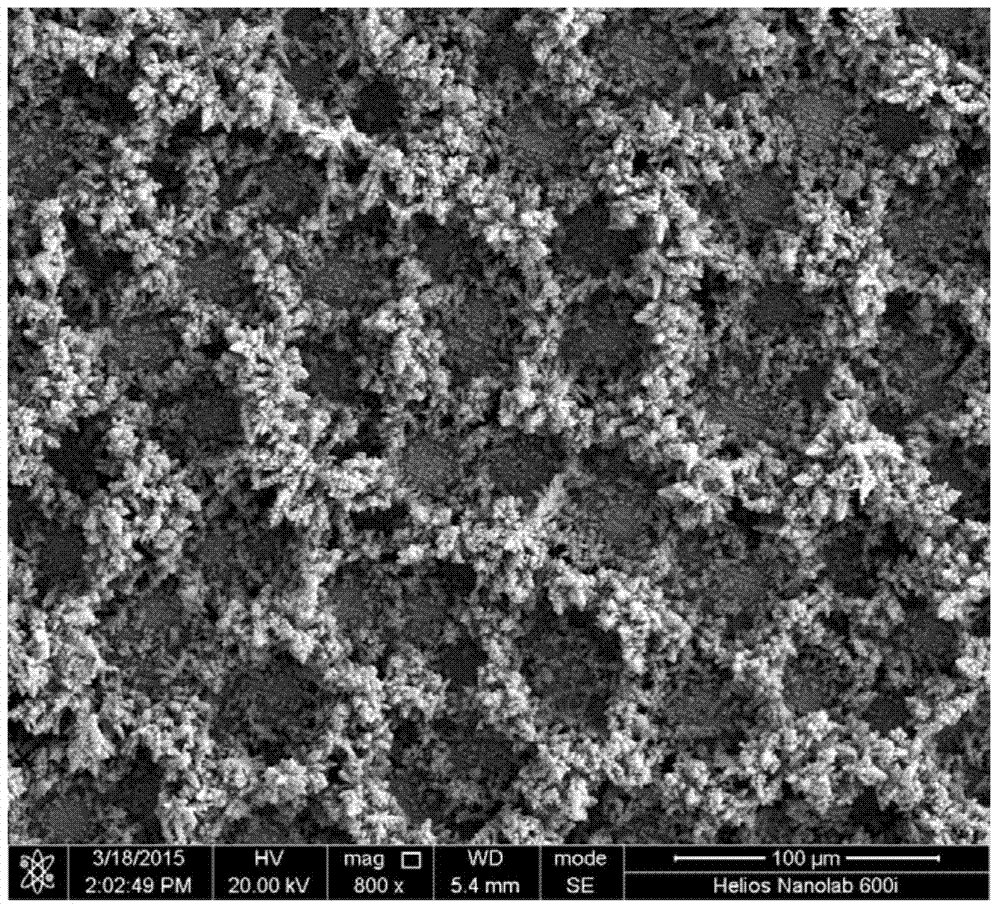

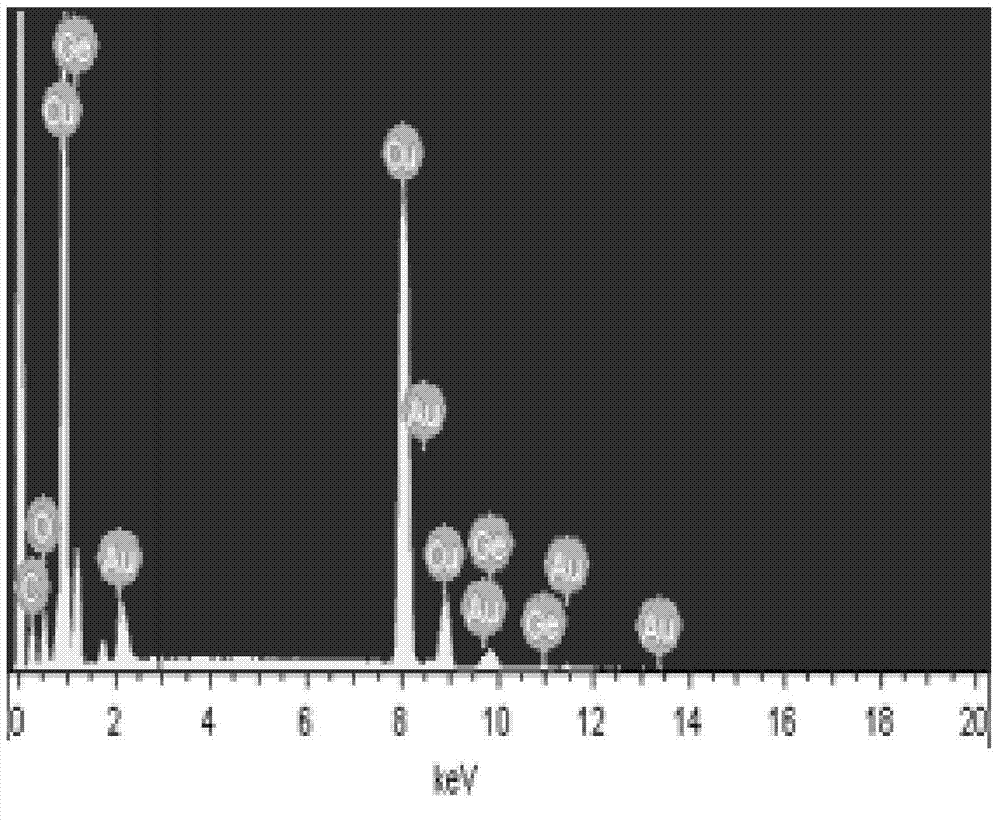

[0027] Specific embodiment 1: A method for preparing porous germanium by ionic liquid electrodeposition described in this embodiment is specifically carried out according to the following steps:

[0028] 1. Hydrogen foam method: Polish the nickel sheet and the pure copper sheet until smooth, remove impurities and surface oxide layers, and obtain the polished nickel sheet and polished pure copper sheet, and connect the polished nickel sheet to the negative electrode of the DC power supply Connect to get the negative pole piece, connect the polished pure copper piece to the positive pole of the DC power supply to get the positive pole piece, then place the positive pole piece and the negative pole piece in the electrolyte, and set the voltage of the DC power supply to 2V ~ 20V , the current is 0.1A~5A, and the reaction is 5s~20s, and the porous metal copper foil is obtained;

[0029] The distance between the positive pole piece and the negative pole piece is 1 cm to 10 cm; the e...

specific Embodiment approach 2

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the voltage of the DC power supply is set to 20V, and the current is 5A. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the distance between the positive pole piece and the negative pole piece described in step 1 is 8 cm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com