A Drying System Containing Combined Reversing Valve

A drying system and reversing valve technology, applied in multi-port valves, valve devices, mechanical equipment, etc., can solve the problems of frequent switching valve failures, short reversing time, and poor reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

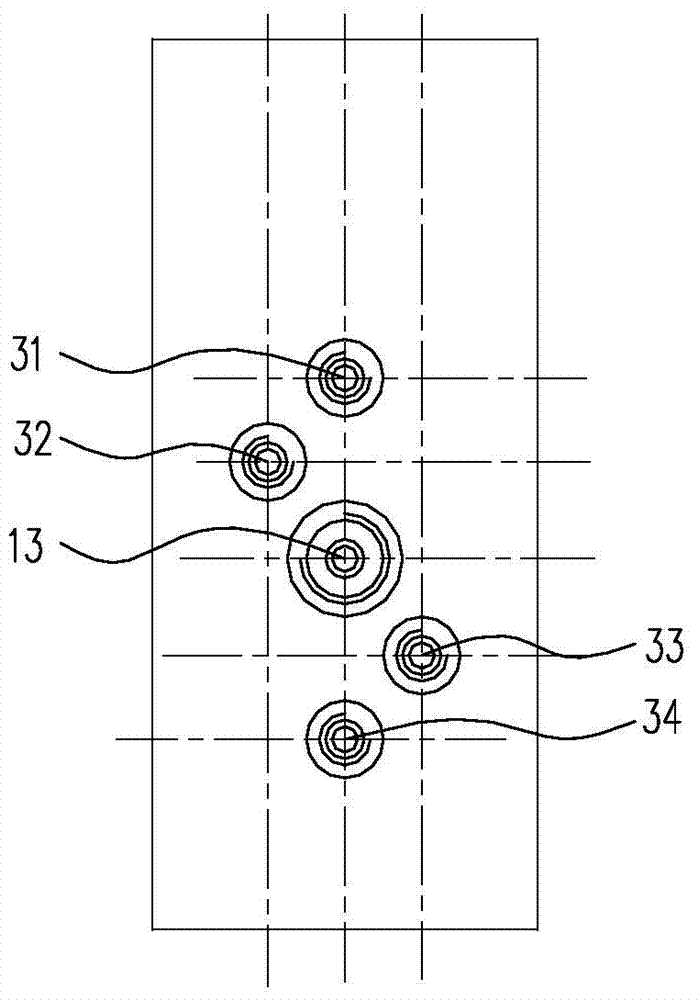

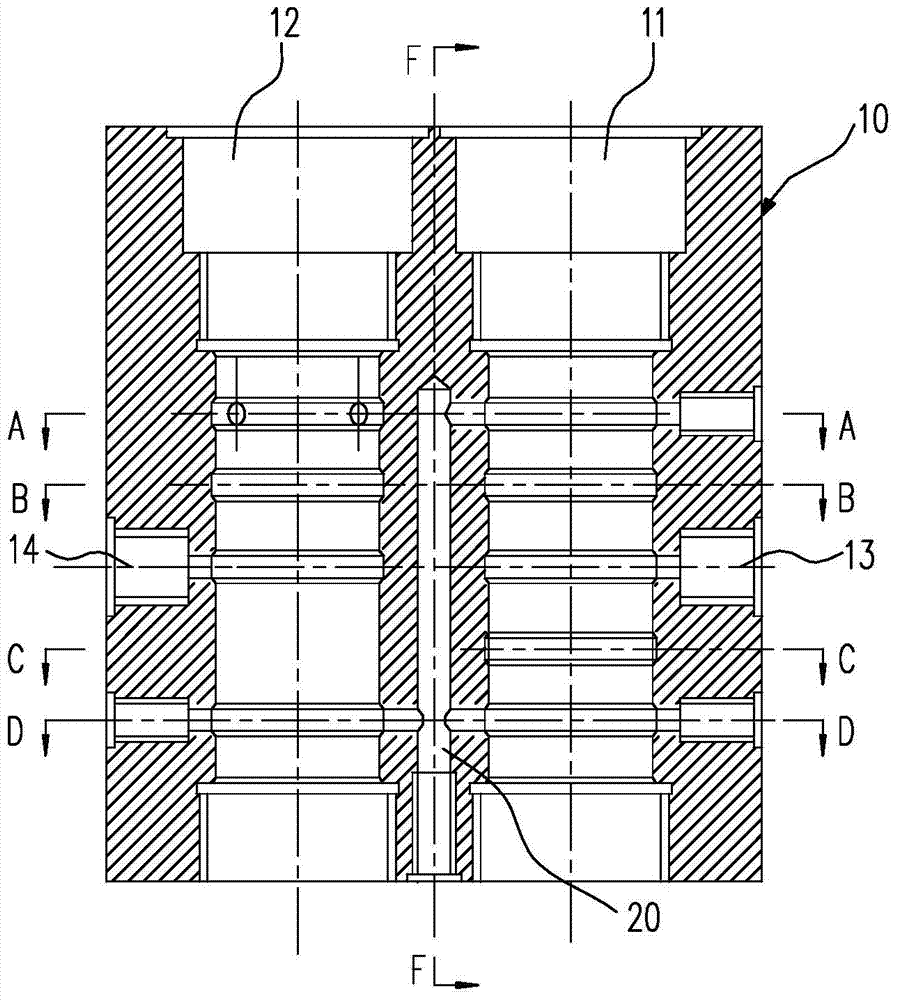

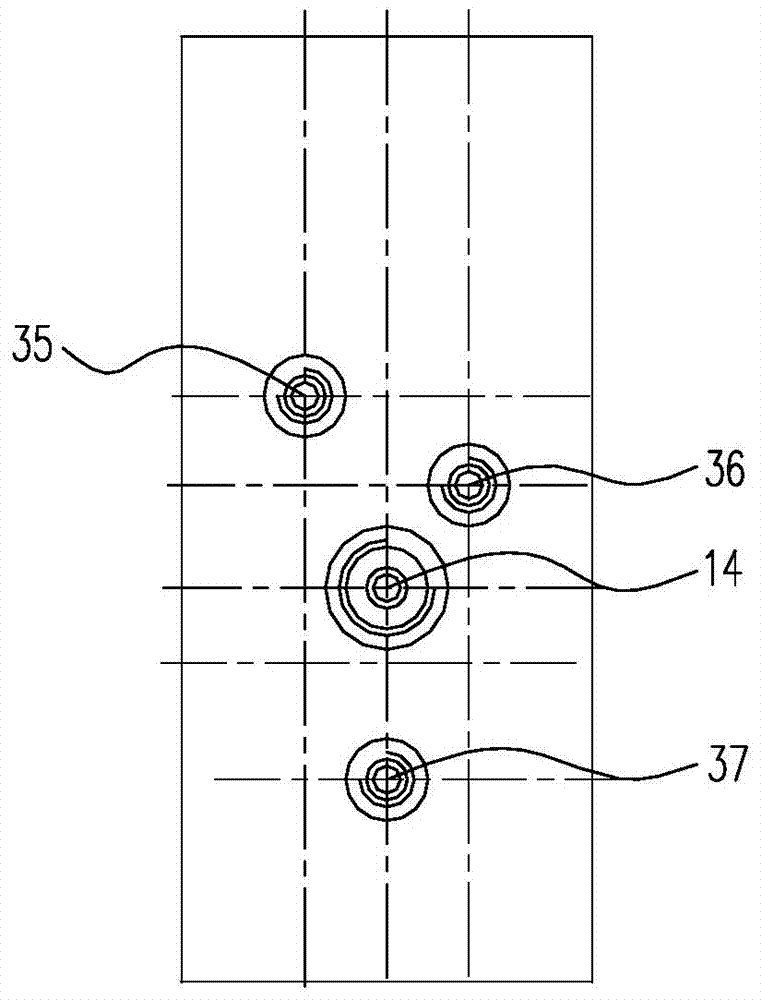

[0090] Reference Figure 1-20 As shown, the drying system containing the combined reversing valve includes an air inlet device 4, an air outlet device 5, two parallel drying towers I drying tower 7 and II drying tower 8, muffler 2, upper pipe system 6, combined reversing The valve 1, and the controller 3, the air intake device 4 is in communication with the air inlet 13 of the combined reversing valve 1, and the muffler 73 is in communication with the regeneration port 14 of the combined reversing valve 1, The M outlet 15 and the N outlet 16 of the combined reversing valve 1 are connected to the inlet ends of the I drying tower 7 and the II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com