Preparation method of polypropylene nano fibers

A technology of nanofibers and polypropylene, which is applied in the field of preparation of organic nanofibers, can solve the problems that fiber quality is difficult to guarantee and cannot be controlled artificially

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of Polypropylene Nanofiber Vertical Immersion Liquid Phase Epitaxy

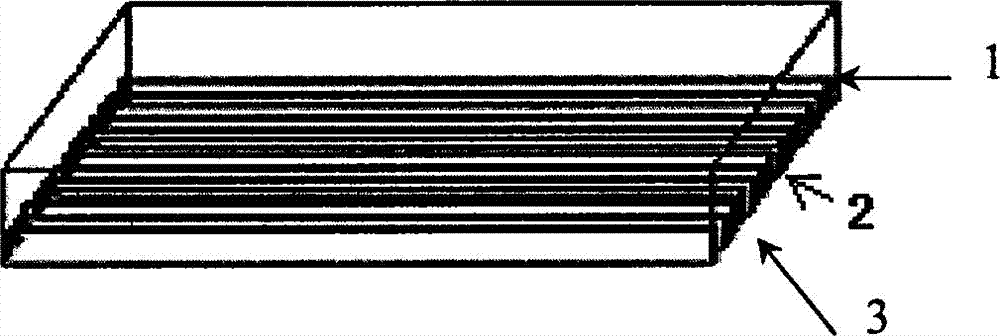

[0018] Attached with plasma or laser beam figure 1 The lower surface shown is precisely polished to an optical grade 1 ABS rectangular substrate. The lower surface of the rectangular substrate is etched with polyvinyl chloride as a mask to form a groove with a width of 0.13 microns and a depth of 0.1 microns. After removing, clean the substrate with ethanol and conductive water, remove the moisture in the cleaned substrate in a muffle furnace at 200°C, dry the substrate, and fix the substrate on the stainless steel seed rod.

[0019] Melt high-grade pure polypropylene powder in a quartz crucible at 180°C for half an hour. After constant temperature, the melt surface temperature is kept at 180°C. The substrate with grooves is driven by the seed rod to contact the surface of the melt for 10 seconds and then breaks away from the melt. The adsorbed melt on the lower surface of the s...

Embodiment 2

[0020] Preparation of Example 2 propylene nanofibers by "small boat method" liquid phase epitaxy

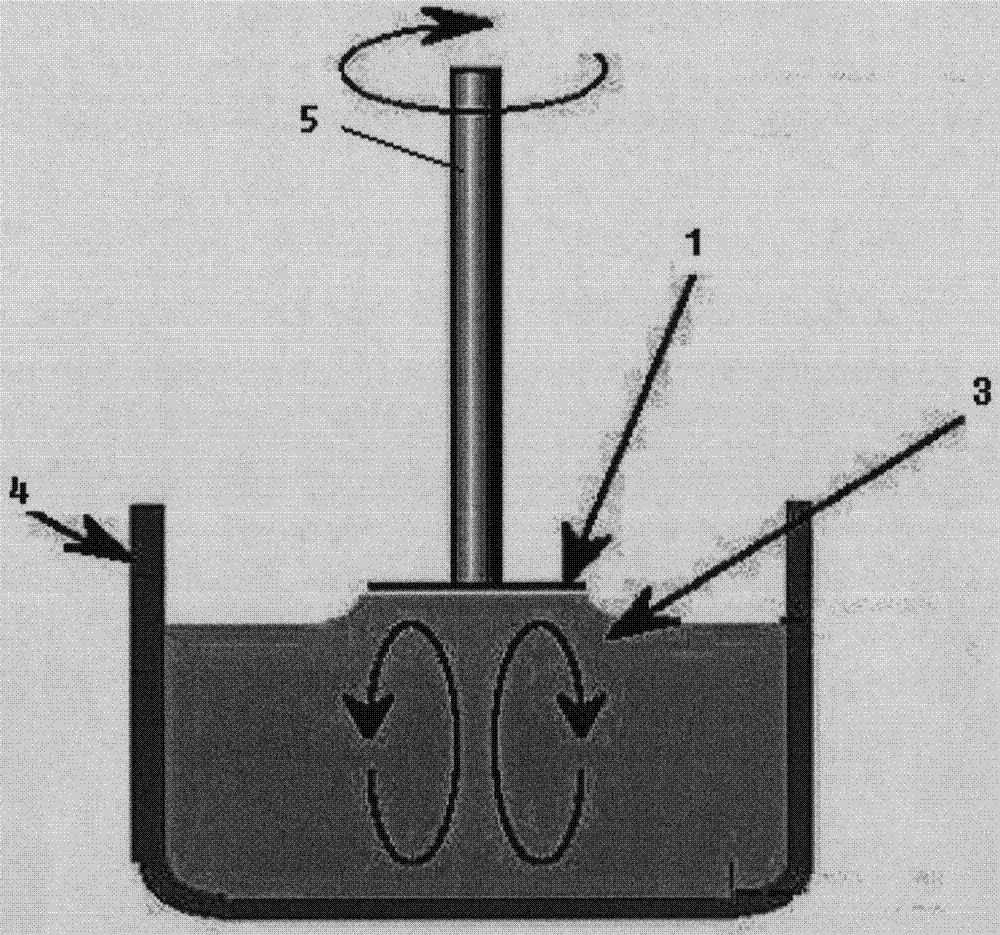

[0021] Attached with plasma or laser beam figure 2 The lower surface shown was precision polished to optical grade 1 ABS. The lower surface of the rectangular substrate was etched into grooves 0.13 microns wide and 0.1 microns deep.

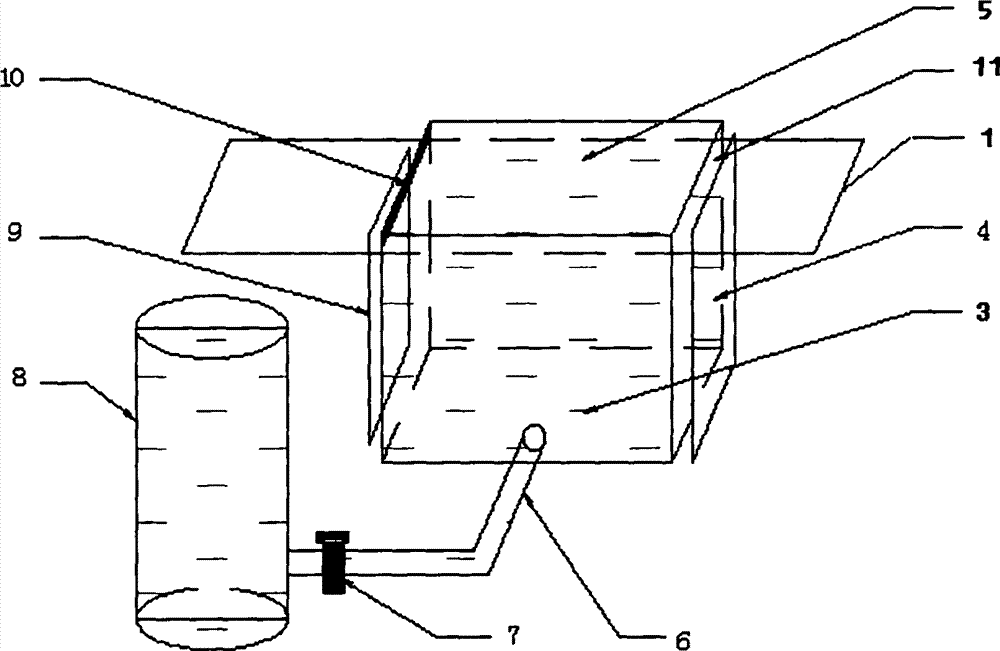

[0022] The molten polypropylene melt was placed in the attached image 3 The shown constant temperature pool is full, and the temperature of the upper part of the melt in the constant temperature pool is 170°C, which is the melting point of polypropylene. On the right side of the constant temperature pool, there is an elastic scraper fixed on the edge of the constant temperature pool, and the neatly opened scraper opens upward. Move the grooved ABS substrate from left to right against the upper part of the constant temperature pool slowly and at a constant speed from left to right. Part of the melt in the constant temperature bath adheres to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com