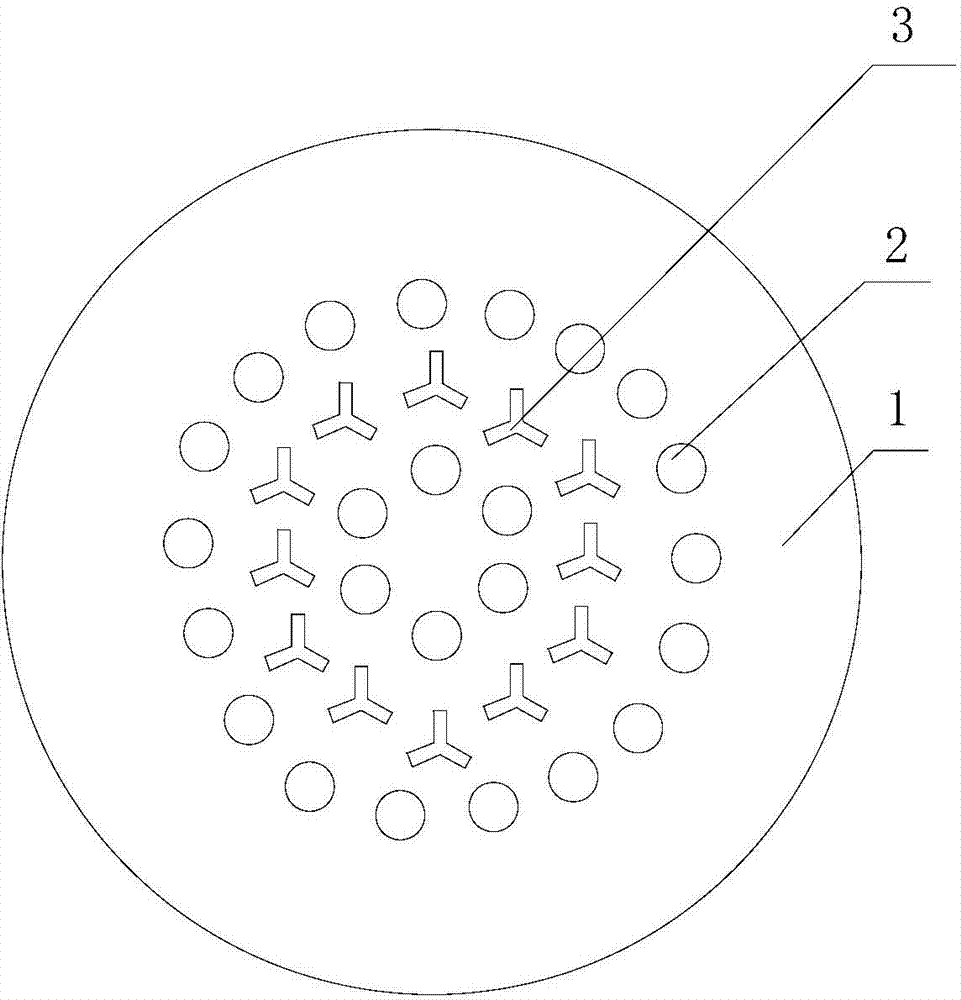

Spinneret plate with circular and trifoliate tiny pores

A spinneret and three-lobe technology, which is applied in filament/thread forming, textile and papermaking, fiber treatment, etc., can solve the problems of poor hygroscopicity and air permeability of fabrics, increase of refraction surface, general gloss effect of cloth surface, etc. Achieve the effects of good hygroscopicity and air permeability, high breaking strength and good flashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] like figure 1 As shown, a spinneret containing circular and trilobal micropores includes a spinneret plate surface 1, and spinneret microholes are arranged on the spinneret plate surface 1, and one side of the spinneret microholes is a feed The other side is the discharge port, the shape of the spinneret plate surface 1 is circular, the spinneret microholes are two or more shapes, the number of spinneret microholes is 24-96, preferably 24-48, Most preferably 36 or 48. The spinneret micropores are arranged in three layers of concentric circles or concentric diamond structures from inside to outside. The shape of the spinneret microholes is composed of a mixture of circular and inline shapes. The trilobal spinneret microholes 3 are arranged in the middle layer of concentric circles or concentric diamond shapes, and the circular spinneret microhol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com