Method and device for performing impact-spraying on inner hole wall based on laser impact wave technology

A shock wave and inner hole technology, which is applied in the field of parts processing and remanufacturing, can solve the problems of poor safety, low spraying efficiency, and difficult parameter control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

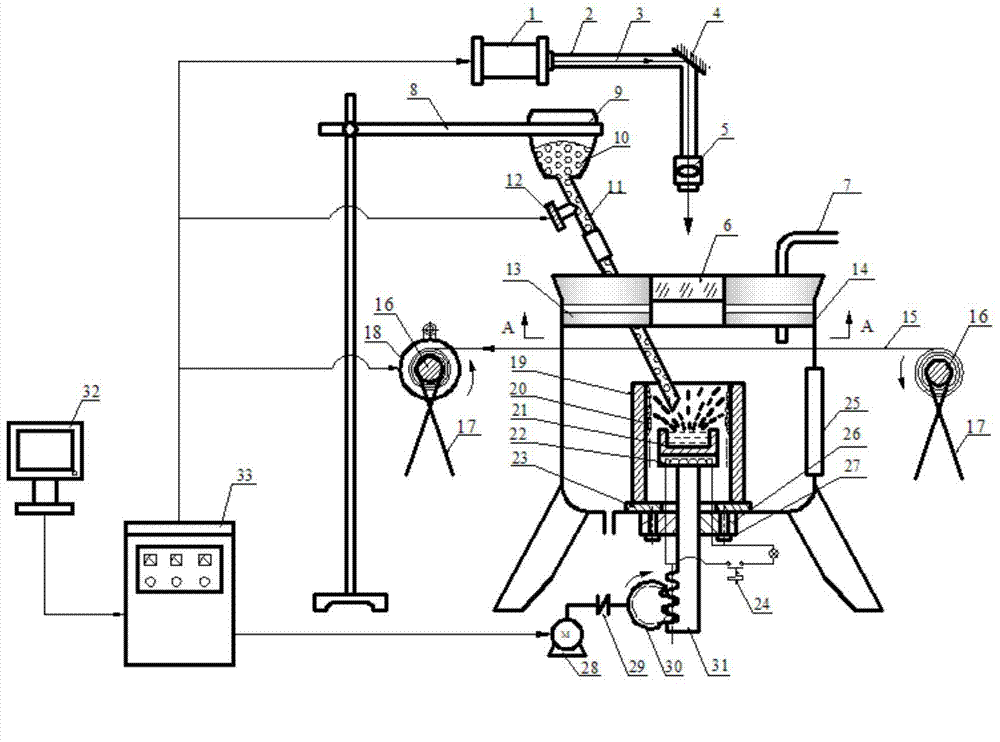

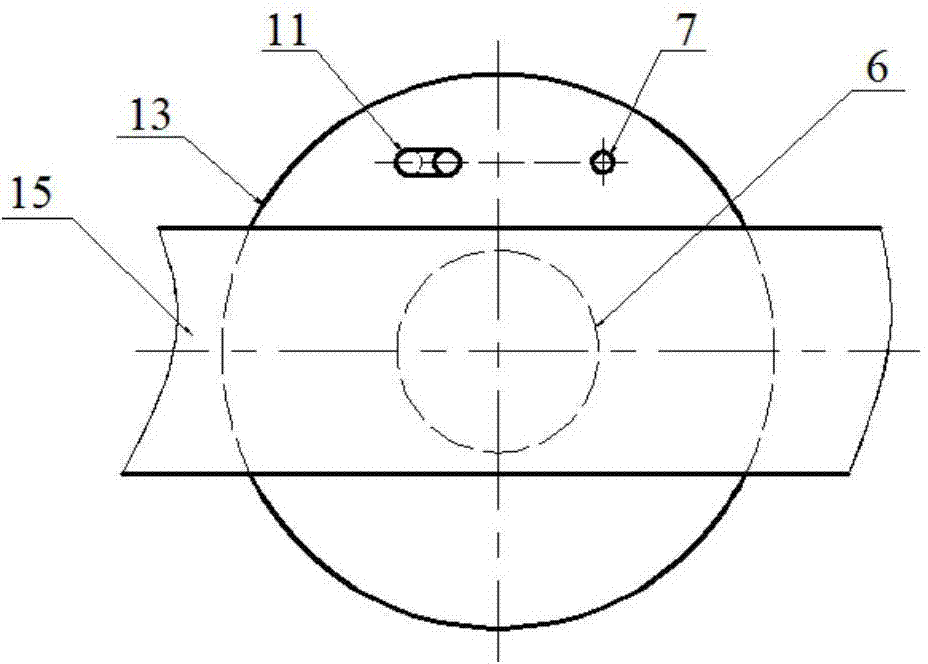

[0037] The device of the present invention includes a laser generator 1, a light guiding system, a powder feeding system, a workpiece fixture system and a control system. Wherein said light guide system includes light guide tube 2, laser pulse beam 3, total reflection mirror 4, impact head 5, transparent glass 6, protective film 15, stick shaft 16, stick shaft support 17, stepper motor 18; The system includes an air inlet pipe 7, a hopper rack 8, a hopper 9, metal powder 10, a powder feeding pipe 11, a powder volume switch 12, a sealing plug 13, and a crucible 21; the workpiece fixture system includes a sputtering chamber 14, a workpiece 19, a crucible 21, Heater 22, adjustment block 23, temperature control switch 24, movable window 25, guide sleeve 26, screw 27, motor 28, coupling 29, gear 30, rack shaft 31; control system includes computer 32 and controller 33 .

[0038] After the above-mentioned system components are installed, a sufficient amount of protective gas is intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com