High-temperature-resistant low-tension foam oil-displacing agent and application thereof

A technology of foam flooding and low tension, which is applied in the field of foam flooding agents, can solve the problems of poor stability and insufficient foam flooding in high-temperature reservoirs, and the foam agent does not have ultra-low interfacial tension, so as to achieve easy large-scale use and increase Effects of foam stabilizing performance, solubility performance and strong high temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

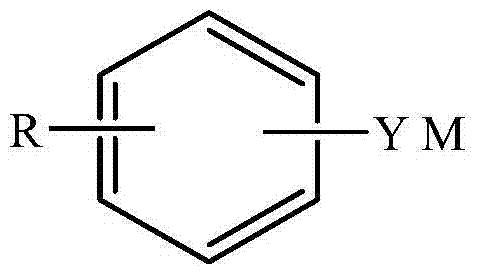

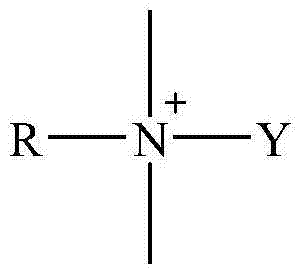

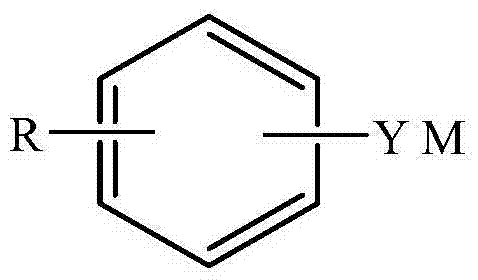

Method used

Image

Examples

Embodiment 1

[0040] Prepare an aqueous solution of a low-tension foam oil displacement agent with high temperature resistance, wherein the mass concentration of sodium tetradecyl α-olefin sulfonate in the aqueous solution is 1.0‰, and the mass concentration of sodium tetradecylbenzenesulfonate is 1.0 ‰, the mass concentration of cetyl betaine is 2.0‰ (mass concentration of anionic surfactant: mass concentration of zwitterionic surfactant=1:1), the mass concentration of sodium chloride is 0.1‰, dodecyl alcohol The mass concentration is 0.1‰.

[0041] The above-mentioned low-tension foam oil displacement agent with high temperature resistance does not decompose at a high temperature of 300°C.

[0042]Take 50 mL of the aqueous solution of the low-tension foam oil-displacing agent with high temperature resistance and pour it into the airflow foam instrument, keep the temperature at 50°C for 30 minutes; use a peristaltic pump at a constant speed (10mL / s) to ventilate the air from the lower part...

Embodiment 2

[0044] Prepare an aqueous solution of a low-tension foam oil displacement agent with high temperature resistance, wherein the mass concentration of sodium dodecyl α-olefin sulfonate in the aqueous solution is 50‰, and the mass concentration of sodium dodecylbenzenesulfonate is 50‰ ‰, the mass concentration of dodecyl betaine is 2.0 ‰ (the mass concentration of anionic surfactant: the mass concentration of zwitterionic surfactant=50:1), the mass concentration of sodium chloride is 15 ‰, calcium chloride The mass concentration of tetradecyl alcohol is 1‰, and the mass concentration of myristyl alcohol is 3‰.

[0045] The above-mentioned low-tension foam oil displacement agent with high temperature resistance does not decompose at a high temperature of 300°C.

[0046] Take 50 mL of the aqueous solution of the low-tension foam oil-displacing agent with high temperature resistance and pour it into the airflow foam instrument, keep the temperature at 50°C for 30 minutes; use a peris...

Embodiment 3

[0048] Prepare an aqueous solution of a low-tension foam oil displacement agent with high temperature resistance, wherein the mass concentration of sodium cetyl sulfonate in the aqueous solution is 1.7‰, the mass concentration of sodium octadecylbenzene sulfonate is 1.7‰, ten The mass concentration of octaalkyl betaine is 2.0‰ (the mass concentration of anionic surfactant: the mass concentration of zwitterionic surfactant=1.7:1), the mass concentration of sodium chloride is 5‰, the mass concentration of calcium chloride is 1.5‰, and the mass concentration of stearyl alcohol is 0.5‰.

[0049] The above-mentioned low-tension foam oil displacement agent with high temperature resistance does not decompose at a high temperature of 300°C.

[0050] Take 50 mL of the aqueous solution of the low-tension foam oil-displacing agent with high temperature resistance and pour it into the airflow foam instrument, keep the temperature at 50°C for 30 minutes; use a peristaltic pump at a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com