A kind of water-soluble polyurethane exterior wall thermal insulation coating and production method thereof

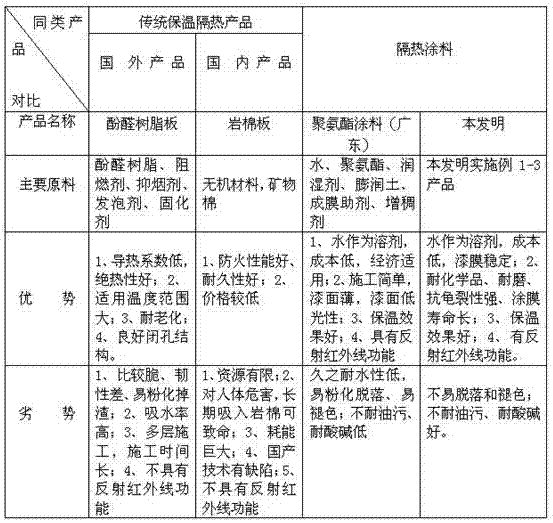

A water-soluble polyurethane, thermal insulation technology, used in polyurea/polyurethane coatings, reflective/signal coatings, coatings, etc., can solve problems such as single function, achieve excellent solubility, improve dryness, and reduce flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

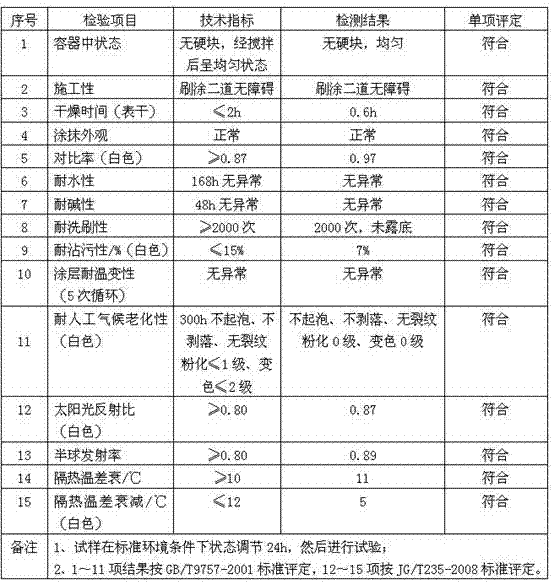

Embodiment 1

[0041] First, according to weight parts, 50 parts of polyurethane prepolymer, 3 parts of N-methylol acrylamide, 2 parts of diisooctyl maleate, 0.7 parts of aniline methyl trimethoxysilane, 15 parts of rutile titanium dioxide Parts, 0.3 parts of defoamer silica TS-4400, 5 parts of superfine talcum powder, 13 parts of mixed solvent (mixture of propylene glycol methyl ether and water, weight ratio 2:11), 6 parts of hollow glass beads; leveling agent nitration Prepare 2 parts of cellulose and 2 parts of iron oxide yellow.

[0042] Production method: add 2.2 kg of ethanol with a volume concentration of 65-85% per kg of N-methylol acrylamide by weight to dissolve it, and then mix it with the polyurethane prepolymer in the reactor at a reaction temperature of 80°C and a reaction time of 2 hours. Add aniline methyl trimethoxy silane; continue the reaction for 6 hours; then add diisooctyl maleate, rutile titanium dioxide, silica TS-4400, superfine talcum powder, leveling agent, iron oxide...

Embodiment 2

[0044] First, according to weight parts, 55 parts of polyurethane prepolymer, 4 parts of N-methylolacrylamide, 3 parts of diisooctyl maleate, 0.9 parts of aniline methyl trimethoxysilane, and 18 parts of rutile titanium dioxide Parts, 0.4 parts of defoamer silica TS-4400, 7 parts of superfine talc, 15 parts of mixed solvent (mixture of propylene glycol methyl ether and water, weight ratio 2:11), 8 parts of hollow glass beads; Prepare 4 parts of N-methylpyrrolidone solution of polyurea and 1 part of iron oxide red.

[0045] Production method: add 2.2 kg of ethanol with a volume concentration of 65-85% per kg of N-methylol acrylamide by weight to dissolve it, and then mix it with the polyurethane prepolymer in the reactor. The reaction temperature is 110°C and the reaction time is 1.5 hours later. Add aniline methyl trimethoxy silane; continue the reaction for 4 hours; then add diisooctyl maleate, rutile titanium dioxide, silica TS-4400, ultrafine talcum powder, anti-settling agent...

Embodiment 3

[0047] First, according to weight parts, 60 parts of polyurethane prepolymer, 5 parts of N-methylol acrylamide, 5 parts of diisooctyl maleate, 1.2 parts of aniline methyl trimethoxysilane, and 20 parts of rutile titanium dioxide Parts, 0.5 parts of defoamer silica TS-4400, 10 parts of superfine talc, 16 parts of mixed solvent (mixture of propylene glycol methyl ether and water, weight ratio 2:11), 10 parts of hollow glass beads; Antifreeze B 6 parts of diol and 2 parts of toluidine red were prepared.

[0048] Production method: add 2.2 kg of ethanol with a volume concentration of 65-85% per kg of N-methylol acrylamide by weight to dissolve it, and then mix it with the polyurethane prepolymer in the reactor. The reaction temperature is 140°C. After 1 hour of reaction Add aniline methyl trimethoxysilane; continue the reaction for 2 hours; then add diisooctyl maleate, rutile titanium dioxide, silica TS-4400, ultrafine talc, antifreeze, toluidine red , Mix solvent and hollow glass b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com