Reduced and reinforced type polycarboxylate having high water-reducing rate and preparation method thereof

A high water-reducing rate, polycarboxylate technology, applied in the field of high water-reducing rate polycarboxylate and its preparation, can solve the problems of lack of shrinkage reduction, enhancement, and inability to reduce the surface tension of aqueous solutions, and achieve excellent Water reduction and slump retention effect, obvious shrinkage reduction effect, and compressive strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

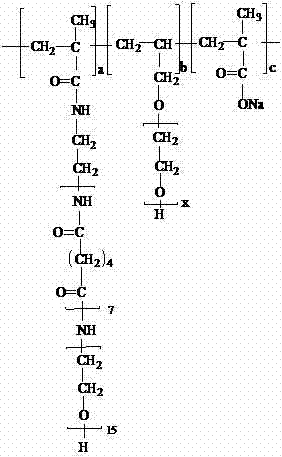

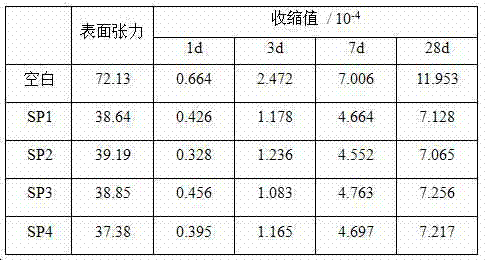

[0026] The preparation method of the shrinkage-reducing enhanced high water-reducing rate polycarboxylate of this embodiment is as follows:

[0027] (1) Radical polymerization: 21.6 g of methacrylic acid, 120 g of allyl polyoxyethylene ether with an average molecular weight of 2400, 2 g of acrylamide, 15 g of maleic anhydride and 350 g of deionized water were added to the reactor, under nitrogen protection Stir evenly, heat up to 65°C, add ammonium persulfate aqueous solution (1.6g ammonium persulfate dissolved in 100g water) and thioglycolic acid aqueous solution (1g thioglycolic acid dissolved in 100g water) dropwise at a rate of 1mL / min, and keep stirring for 3 h , keep warm for 1 h at 55°C;

[0028] (2) Cooling and neutralization: Cool to room temperature, and adjust the pH value to 7 with 1mol / L NaOH aqueous solution to obtain a shrinkage-reducing enhanced high water-reducing polycarboxylate, which is designated as water-reducing agent SP1.

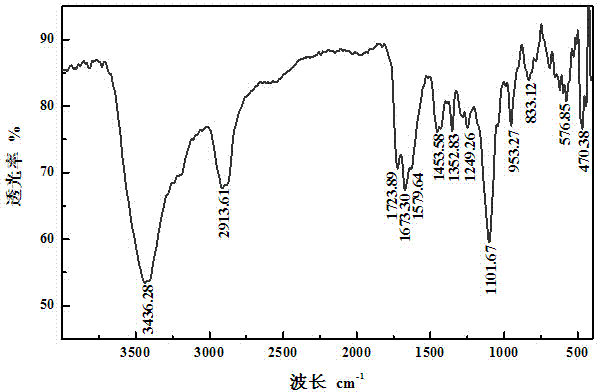

[0029] The infrared spectrog...

Embodiment 2

[0031] The preparation method of the shrinkage-reducing enhanced high water-reducing rate polycarboxylate of this embodiment is as follows:

[0032] (1) Free radical polymerization: 21.6 g of methacrylic acid, 130 g of allyl polyoxyethylene ether with an average molecular weight of 3400, 1 g of acrylamide, 18 g of maleic anhydride and 300 g of deionized water were added to the reactor, under nitrogen protection Stir evenly, heat up to 70°C, add ammonium persulfate aqueous solution (1.6g ammonium persulfate dissolved in 100g water) and thioglycolic acid aqueous solution (1g thioglycolic acid dissolved in 100g water) dropwise at a rate of 2mL / min, and continue stirring for 4 h , keep warm for 1.5 h at 60°C;

[0033] (2) Cooling and neutralization: Cool to room temperature, and adjust the pH value to 7 with 1mol / L NaOH aqueous solution to obtain a shrinkage-reducing enhanced high water-reducing polycarboxylate, which is designated as water-reducing agent SP2.

Embodiment 3

[0035] The preparation method of the shrinkage-reducing enhanced high water-reducing rate polycarboxylate of this embodiment is as follows:

[0036](1) Radical polymerization: 21.6 g of methacrylic acid, 150 g of allyl polyoxyethylene ether with an average molecular weight of 4000, 1.5 g of acrylamide, 12 g of maleic anhydride and 250 g of deionized water were added to the reactor, under nitrogen protection Stir evenly, heat up to 75°C, add ammonium persulfate aqueous solution (1.6g ammonium persulfate dissolved in 100g water) and thioglycolic acid aqueous solution (1g thioglycolic acid dissolved in 100g water) dropwise at a rate of 3mL / min, and keep stirring for 4 h , keep warm for 2 hours at 65°C;

[0037] (2) Cooling and neutralization: Cool to room temperature, and adjust the pH value to 7 with 1mol / L NaOH aqueous solution to obtain a shrinkage-reducing enhanced high water-reducing polycarboxylate, which is designated as water-reducing agent SP3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com