An energy-saving and environmentally friendly production system for solid polyaluminum chloride using heat-conducting oil-type drum drying

A drum drying, polyaluminum chloride technology, applied in aluminum chloride, aluminum halide, chemical industry and other directions, can solve the problems of separation, uneven heating, difficult insoluble matter, etc., achieve simple and efficient process flow, improve output and quality , to achieve the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

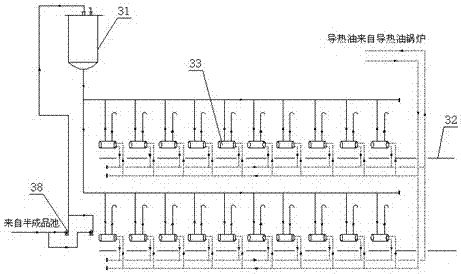

[0040] The energy-saving and environment-friendly production system of solid polyaluminum chloride using heat-conducting oil-type drum drying of the present invention includes a one-step reaction system, a two-step reaction system, a drying system and a boiler system.

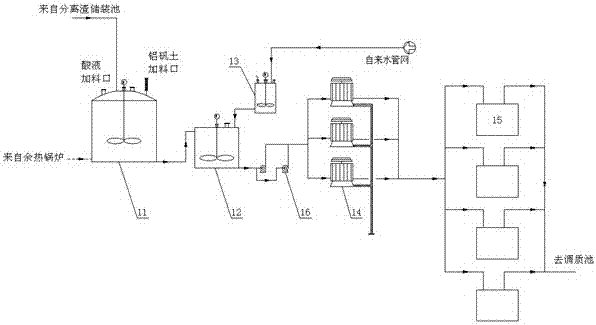

[0041] figure 1It is a structural schematic diagram of a one-step reaction system. As shown in the figure, the one-step reaction system includes a reaction tank 11, a reaction tank transfer tank 12, a flocculant preparation tank I13, a main filter press 14, and a one-step liquid tank 15. On the reaction tank 11 A bauxite feeding port and an acid liquid feeding port are provided, the reaction pool 11 is connected to the reaction pool transfer pool 12, the flocculant preparation tank I13 is connected to the reaction pool transfer pool 12, and the reaction pool transfer pool 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com