Non-layered cross-linked graphene oxide film as well as preparation method and application thereof

A graphene film, non-layered technology, applied in the field of non-layered cross-linked graphene oxide film and its preparation, can solve the problems of layered graphene oxide film being unable to meet demand, increasing fluid resistance, long diffusion path and the like , to achieve high flux and anti-pollution performance, high water flux and retention rate, and low water penetration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Ultrasound 16mg graphene oxide (GO) in 2ml deionized water for 1.5 hours to obtain a uniform aqueous dispersion of graphene oxide, add 4mol / L sodium hydroxide solution to pH = 12.8, add 0.25ml concentration of 16mg / ml Hyperbranched polyethyleneimine (PEI) aqueous solution, stirred vigorously to form a graphene oxide sol, then slowly and evenly added the graphene oxide sol to the non-woven fabric in the petri dish, put the petri dish in a sealed tank at 80°C After 8 hours of treatment, filter and wash with a large amount of water to remove residual sodium hydroxide and unreacted hyperbranched polyethyleneimine, that is, to prepare a non-layered cross-linked graphene oxide film.

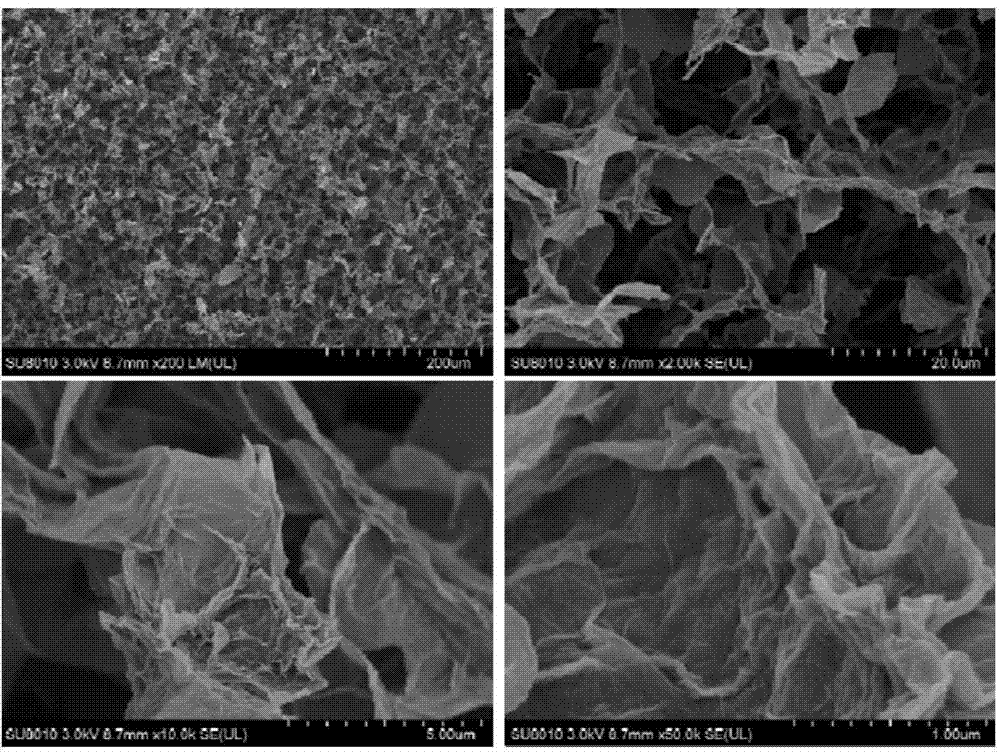

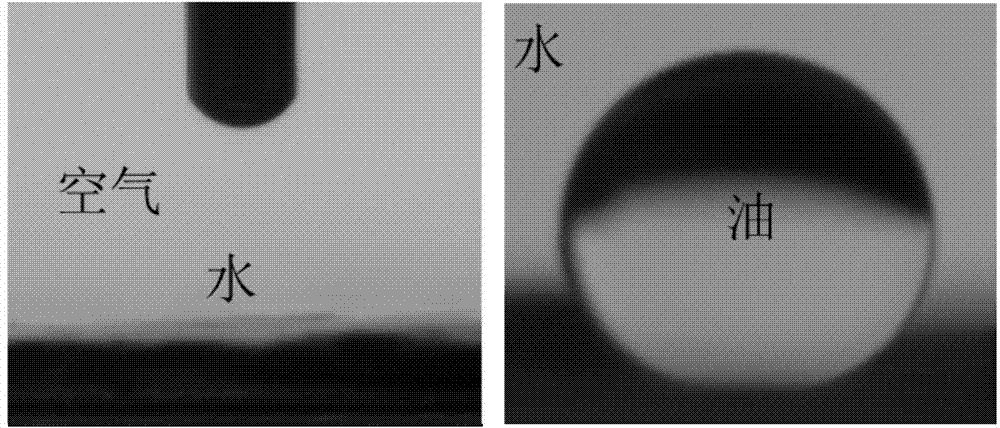

[0032] figure 1 and figure 2 Respectively, the cross-sectional view and surface view of the non-layered cross-linked graphene oxide film prepared in this example, it can be seen from this figure that the cross-section of the non-layered cross-linked graphene oxide film presents a homogeneous s...

Embodiment 2

[0043] Ultrasonicate 16 mg graphene oxide in 2 ml deionized water for 1.5 hours to obtain a uniform aqueous dispersion of graphene oxide, add 4 mol / L sodium hydroxide solution to pH = 12.8, add 0.5 ml hyperbranched polycarbonate with a concentration of 16 mg / ml Aqueous amide solution, stirred vigorously to form graphene oxide sol, then slowly and evenly drop the graphene oxide sol onto the non-woven fabric in the petri dish, put the petri dish in a sealed tank at 80°C for 8 hours, then filter with plenty of water Cleaning, to remove residual sodium hydroxide and unreacted hyperbranched polyamide, promptly makes non-layered cross-linked graphene oxide film.

[0044] The prepared non-layered cross-linked graphene oxide membrane was placed on a suction filtration device for oil-water separation test. Experimental process is identical with embodiment 1.

[0045] It is measured that the rejection rate of this PEI crosslinked non-layered graphene oxide membrane to toluene / water emu...

Embodiment 3

[0047] Ultrasound 20mg of graphene oxide in 2ml of deionized water for 1.5 hours to obtain a uniform graphene oxide water dispersion, add 0.25ml of aqueous solution of butanediamine with a concentration of 16mg / ml, stir vigorously to form a graphene oxide sol, and then add graphite oxide Slowly and evenly drop the alkene sol onto the non-woven fabric in the petri dish, put the petri dish into a sealed tank at 80°C and treat it for 8 hours, then filter and wash it with a lot of water to remove unreacted butanediamine, and then obtain the non-woven fabric Layered crosslinked graphene oxide films.

[0048] The prepared non-layered cross-linked graphene oxide membrane was placed on a suction filtration device for oil-water separation test. Experimental process is identical with embodiment 1.

[0049] It is measured that the rejection rate of this PEI crosslinked non-layered graphene oxide membrane to toluene / water emulsion, n-hexane / water emulsion, n-octane / water emulsion and Iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com