Rolling bearing performance degradation evaluation device and method

A rolling bearing and evaluation device technology, which is applied in measurement devices, mechanical bearing testing, vibration testing, etc., can solve problems such as inability to determine the location of initial damage, inconsistency with the development trend of bearing failure degree, etc., to ensure correctness and effectiveness, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

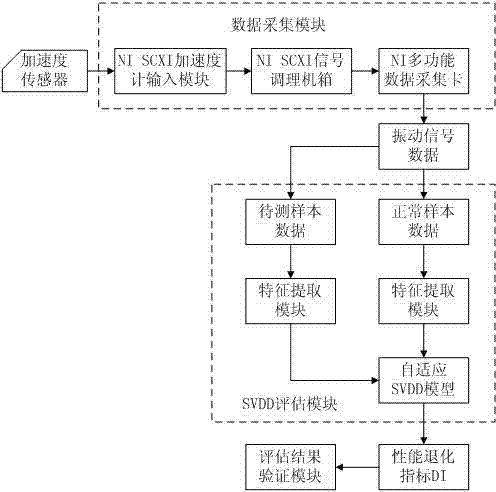

[0042] Embodiments of the present invention relate to a rolling bearing performance degradation evaluation device, such as figure 1 shown.

[0043] This embodiment is a rolling bearing performance degradation evaluation device, including an acceleration sensor, a data acquisition module, a feature extraction module, an SVDD evaluation module and a verification module.

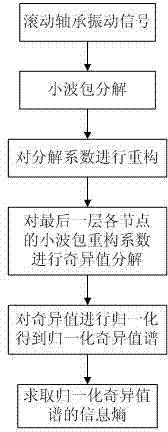

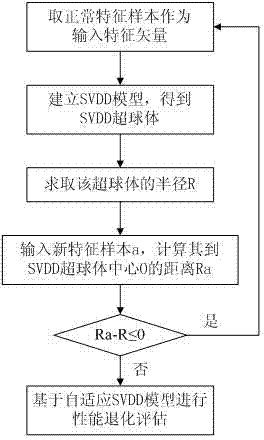

[0044]The acceleration sensor is used to collect the vibration signal of the bearing to be tested and convert the vibration signal into an analog signal; the data acquisition module is used to amplify and filter the analog signal and convert it into a digital signal, and then transmit the digital signal to computer, and stored as data files; the feature extraction module is used to extract the wavelet packet singular spectral entropy of the vibration signal as the input feature vector, for the use of the evaluation model in the SVDD evaluation module; the SVDD evaluation module is used to set up an adaptive SVD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com