Utilization method of medium and low temperature waste heat and its pressure-reducing heat-absorbing steam power cycle system

A low-temperature waste heat and steam power technology, which is applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low utilization rate of medium and low temperature waste heat, and achieve the effect of low utilization rate and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

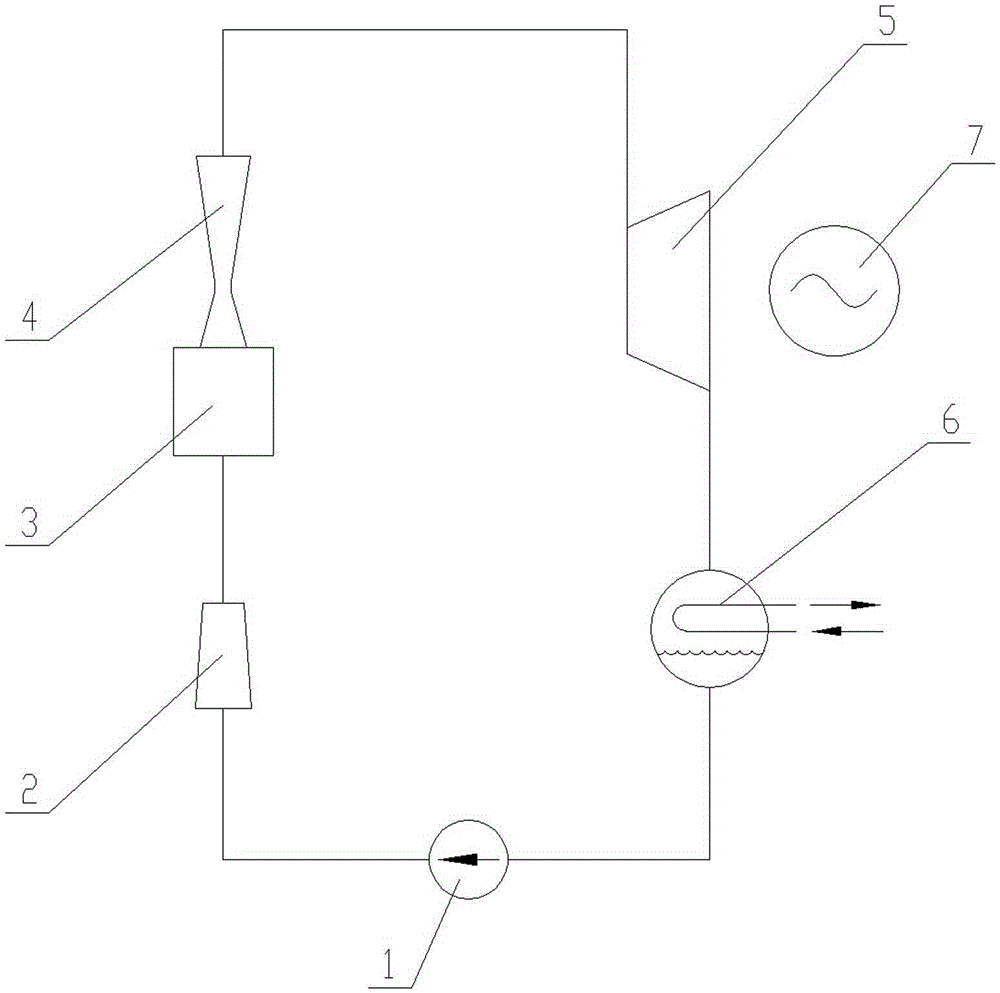

[0014] See figure 1 ,

[0015] A method for utilizing medium and low temperature waste heat, comprising the following steps,

[0016] (1) The high-pressure liquid from the feed pump 1 expands in the expansion pipe 2, so that the flow rate of the high-pressure liquid is accelerated and the pressure drops. When the pressure drops to the point where it can absorb heat from the medium and low temperature waste heat and vaporize it, it enters the heater 3;

[0017] (2) The depressurized liquid enters the heater 3 to be heated and vaporized. In the heater 3, the medium and low temperature waste heat heats the liquid, and the liquid absorbs heat from the medium and low temperature waste heat to vaporize, and the steam flow rate increases rapidly;

[0018] (3) The vapor flow formed after the vaporization of the liquid is diffused in the diffuser tube 4, its kinetic energy decreases, its pressure and temperature rise, and it becomes high-temperature and high-pressure steam;

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com