A method for leaching copper in waste printed circuit boards with mixed bacteria

A printed circuit board and mixed bacteria technology, which is applied in the directions of microorganism-based methods, methods of using microorganisms, biochemical equipment and methods, etc., can solve the problems such as the decline of copper leaching ability, and achieve the improvement of copper leaching rate and simple process. , to promote the effect of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0029] The method for the mixed bacteria of the present embodiment to extract copper in waste printed circuit boards may further comprise the steps:

[0030] ① Pretreatment of waste printed circuit boards. The waste printed circuit board PCBs from which electronic components have been removed are crushed and ground into powder, and the ground waste PCBs powder passes through a sieve of 100 μm to 200 μm (in this example, the waste printed circuit board powder obtained through grinding passes through a 100 μm sieve) , to collect the waste PCBs powder passing through the sieve for processing.

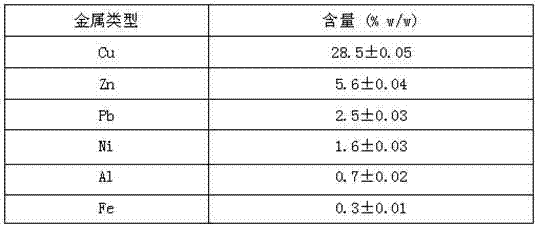

[0031] After the discarded PCBs processed in this embodiment were ground and sieved, their main metal content was analyzed.

[0032] The main metal content is shown in Table 1 below:

[0033] Table 1 Main metal content in waste printed circuit board powder

[0034]

[0035] ② domestication of strains.

[0036] (1) Acidophilus Thiobacillus ferrooxidans ( A. ferrooxidans ) of domest...

Embodiment 2 to Embodiment 6)

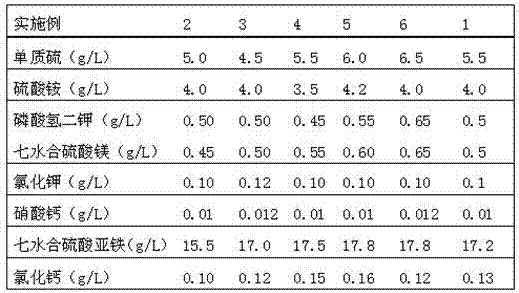

[0065] The mixed bacteria of embodiment 2 to the method of embodiment 6 leaching copper in the waste printed circuit board all the other are the same as embodiment 1, difference is: the content of each component in the mixed bacteria culture solution used when step 3. mixed bacteria culture As well as the addition time and amount of waste printed circuit board powder in step ④, see Table 2 and Table 3 below for details.

[0066] Table 2 The content of each component in the mixed bacteria culture solution used in step ③ mixed bacteria culture

[0067]

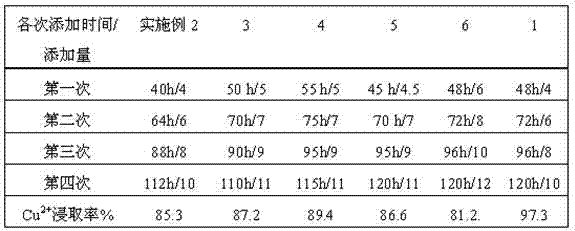

[0068] Table 3 Addition time and amount of waste printed circuit board powder in step ④

[0069]

[0070] Note: The addition time mentioned in the above table refers to the time for powder addition after the start of the mixed bacteria culture in step ③; the added amount refers to the weight of waste printed circuit board powder added per 1L of mixed bacteria culture system , the unit is grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com