Grain-oriented electrical steel sheet and manufacturing method thereof

A technology for oriented electrical steel sheets and manufacturing methods, which is applied in the coating process and coating of metal materials, can solve the problems that it is difficult to ensure the improvement rate of iron loss and cannot show the improvement effect of iron loss, and achieve excellent iron loss improvement rate, High resistivity, effect of suppressing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] The slab is reheated to 1150° C. and then hot-rolled to produce a hot-rolled steel sheet. The slab contains C: 0.0030%, Si: 3.0%, S: 0.001%, Al: 0.05%, N : 0.0013%, Mn: 0.2%, and the balance is Fe and other unavoidable impurities. This hot-rolled steel sheet is coiled, cooled, pickled, and then cold-rolled to produce a cold-rolled steel sheet.

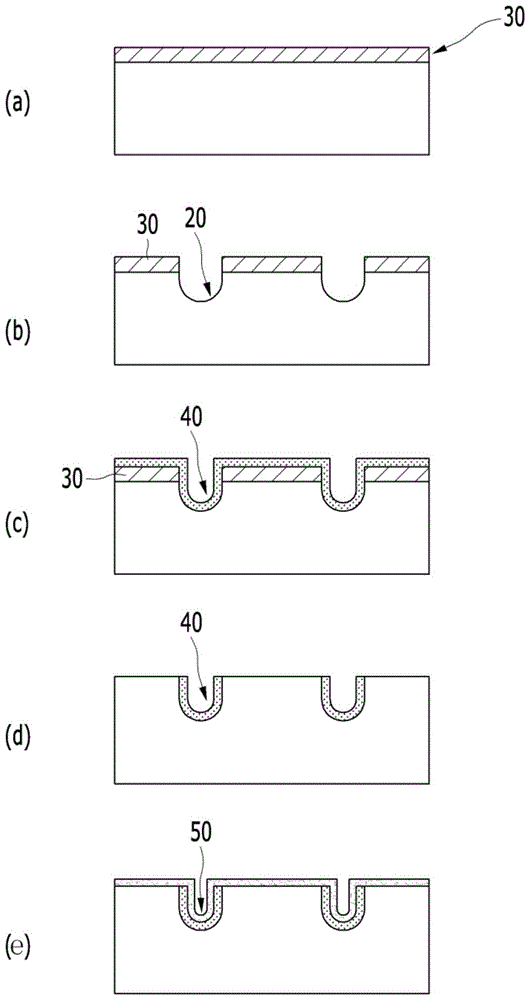

[0075] The thickness of the cold-rolled steel sheet was 0.23 mm, and an organic layer composed of novolac resin, diazide compound, and volatile organic solvent was formed on the surface of the cold-rolled steel sheet with a thickness of 1 μm.

[0076] Grooves are formed by irradiating the surface of the steel sheet coated with the organic layer with a continuous wave laser.

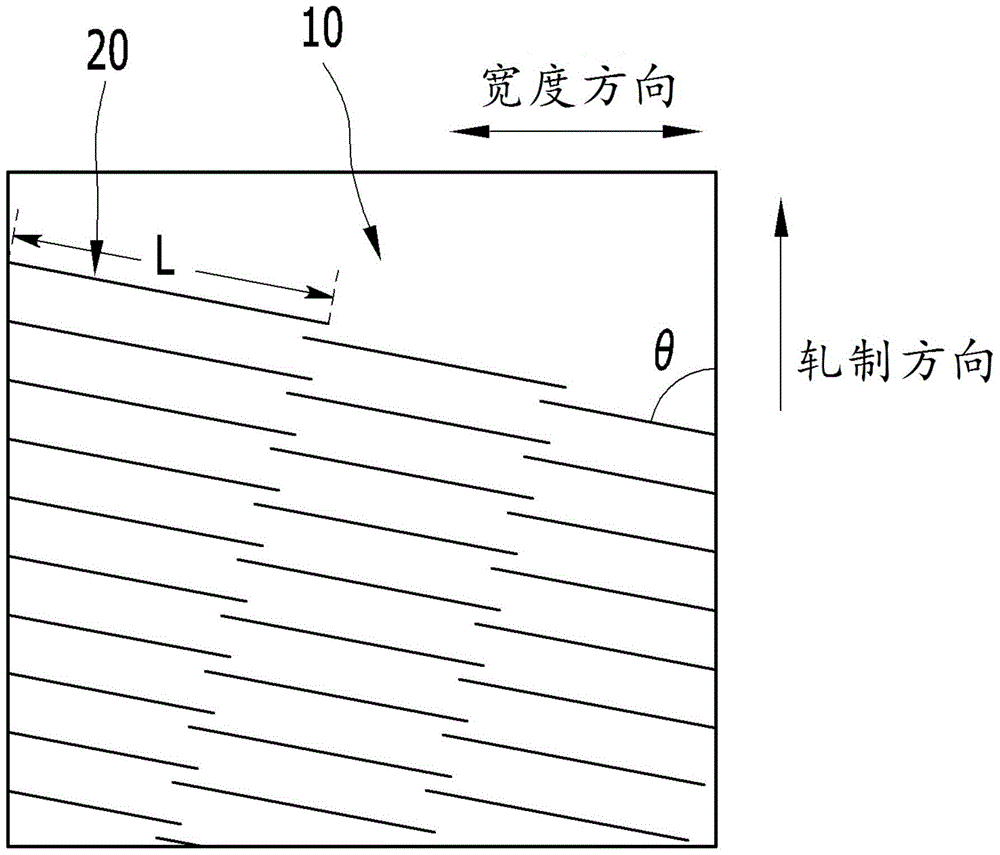

[0077] At this time, the laser energy density E d 1.0J / mm 2 , and are scanned at 87° relative to the rolling direction. Moreover, at this time, the scanning lines of the continuous wave laser are scanned separately along the width direction, such as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| beam width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com