Decarbonization and total nitrogen removal treating process for semi-coking wastewater

A technology for the treatment of charcoal wastewater and nitrogen, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve problems such as affecting the efficiency of ammonia nitrogen treatment, difficulty in treatment, and unattainable effluent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

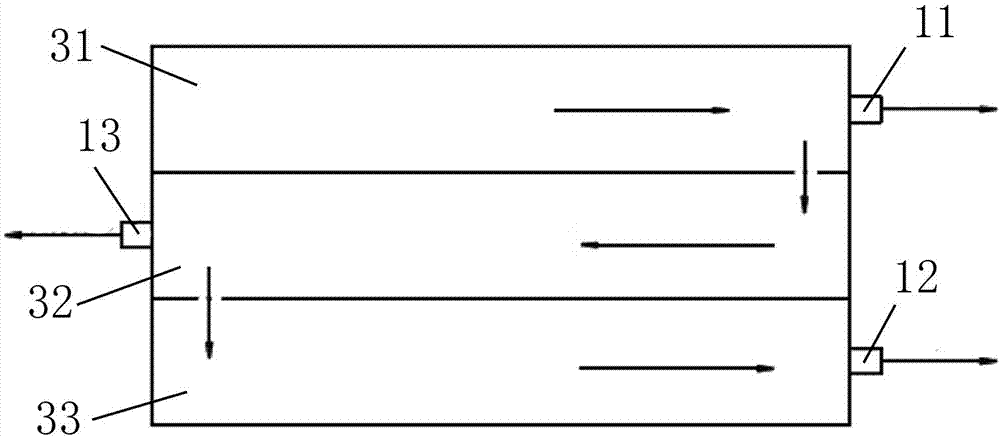

[0021] According to figure 1 The process flow chart to illustrate the specific implementation process:

[0022] figure 1 Among them, A is blue charcoal wastewater; B is residual ozone; C is residual sludge; D is sludge return; E is mixed liquid return; F is effluent or reuse. The blue charcoal wastewater in this project comes from the wastewater of a blue charcoal production plant after ammonia distillation, dephenolization, and deoiling. It is composed of phenolic wastewater and oily wastewater (at a 4:6 inflow). Water quality indicators As shown in Table 1, press figure 1 The design of the process flow is 1m 3 / h device runs, the processing process is as follows:

[0023]

[0024] 1) Pretreatment system:

[0025] The blue charcoal wastewater enters the grease trap to remove most of the heavy oil and part of the light oil, enters the conditioning tank for homogenization, and then enters the secondary vortex air flotation treatment. Each level of quaternary amine polymer is about 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com