Flaky platinum powder, and preparation method and application thereof

A manufacturing method and platinum powder technology, which is applied in the field of platinum materials, can solve the problems of platinum electrode leakage and poor heat resistance, and achieve excellent high-temperature sintering performance, high sensitivity, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] (3) Preparation of flaky platinum powder

[0033] Grind the grinding pot in step (2) at a speed of 520 rpm, stop after grinding for 3-8 hours, rinse the metal ball abrasive and the grinding pot with a large amount of absolute ethanol, filter the ground slurry, Obtain solid platinum powder.

[0034] (4) Washing and drying of flake platinum powder

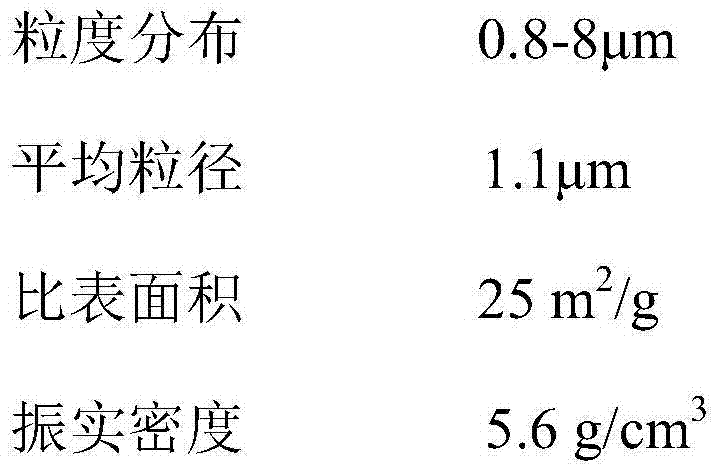

[0035] Wash the platinum powder obtained in step (3) twice with absolute ethanol, and dry it at 60°C to obtain the finished product of flaky platinum powder. The physical parameters of the obtained flaky platinum powder are: particle size distribution of 0.8-8μm, average particle size of 1.0-1.5μm, specific surface area of 15-25m 2 / g, the tap density is 5.0-6.0g / cm 3 , the ratio of diameter to thickness is 20-50:1. Embodiment 1: produce flaky platinum powder 30g

Embodiment 1

[0035] Wash the platinum powder obtained in step (3) twice with absolute ethanol, and dry it at 60°C to obtain the finished product of flaky platinum powder. The physical parameters of the obtained flaky platinum powder are: particle size distribution of 0.8-8μm, average particle size of 1.0-1.5μm, specific surface area of 15-25m 2 / g, the tap density is 5.0-6.0g / cm 3 , the ratio of diameter to thickness is 20-50:1. Embodiment 1: produce flaky platinum powder 30g

[0036] (1) Add ultra-fine platinum powder: Pour 90g of metal ball abrasive with a diameter of 3mm into the grinding tank, add absolute ethanol just enough to submerge the metal ball abrasive, grind, wash until there is no rust, heat at 160°C quickly drying.

[0037] Continue to add 30g to the above grinding jar with an average particle size of 0.7μm and a tap density of 1.2g / cm 3 The ultra-fine platinum powder, the total volume of the ultra-fine platinum powder and the metal ball abrasive shall not exceed 2 / 3 ...

Embodiment 2

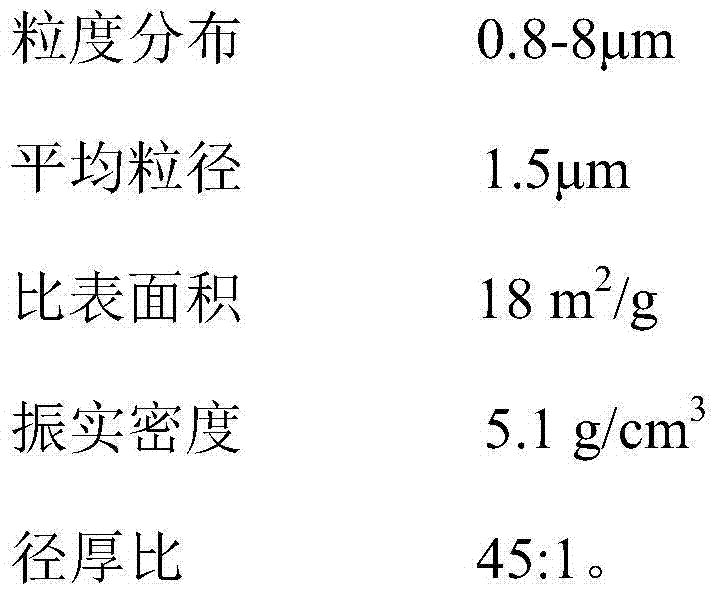

[0044] Embodiment 2: produce flaky platinum powder 30g

[0045] (1) Add ultrafine platinum powder: Pour 90g of metal ball abrasive with a diameter of 5mm into the grinding tank, add absolute ethanol just enough to submerge the metal ball abrasive, grind, wash until there is no rust, heat at 160°C quickly drying.

[0046] Continue to add 30g to the above grinding jar with an average particle size of 0.8μm and a tap density of 1.5g / cm 3 The ultra-fine platinum powder, the total volume of the ultra-fine platinum powder and the metal ball abrasive shall not exceed 2 / 3 of the volume of the grinding tank.

[0047](2) Add medium solution: Add 30ml of 50% ethanol aqueous solution into the grinding tank in step (1).

[0048] (3) Preparation of flaky platinum powder: Grind the grinding pot in step (3) at a speed of 520 rpm, stop after 8 hours of grinding, rinse the metal ball abrasive and the grinding pot with a large amount of absolute ethanol Clean and filter the ground slurry to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com