Preparation method of green metal absorbing material with cellulose and sericin

An adsorption material, green metal technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of non-biodegradability, high production cost, secondary pollution, etc., and achieve rapid hydrolysis reaction, rapid process, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

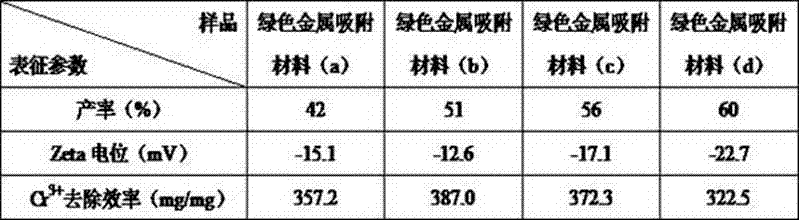

Examples

Embodiment 1

[0022] 1) Grind 1 g of bamboo pulp board with a plant grinder, filter through a 120-mesh screen to obtain bamboo pulp powder with a particle size of 0.12 mm or less, add it to the mixed solution of sodium hydroxide and urea pre-frozen at 2°C, and stir Mix evenly for 6 minutes, wherein the mass fractions of sodium hydroxide and urea are 6 wt% and 13 wt%, respectively, and the mass ratio of sodium hydroxide and urea mixed solution to bamboo pulp board is 55:1, and placed at -14 °C Freeze for 1 h under the same conditions to obtain a uniform and transparent bamboo pulp cellulose solution;

[0023] 2) Thaw the bamboo pulp cellulose solution obtained in step 1) at room temperature, add the oxidizing agent sodium periodate to shading oxidation for 4 h in a water bath at 60°C, and the mass ratio of sodium periodate to bamboo pulp board is 1:1 , to obtain dialdehyde cellulose solution;

[0024] 3) Weigh 1 g of sericin with a molecular weight of 8k Da, add it to 20 mL pH 4.5 acetate b...

Embodiment 2

[0027] 1) Grind 1 g of mottled bamboo pulp with a plant pulverizer, filter through a 120-mesh screen to obtain bamboo pulp powder with a particle size of 0.12 mm or less, add it to a mixed solution of sodium hydroxide and urea pre-frozen at 2°C, and stir for 6 min to make it mix evenly, wherein the mass fractions of sodium hydroxide and urea are 7 wt% and 12 wt% respectively, and the mass ratio of sodium hydroxide and urea mixed solution to mottled bamboo pulp board is 25: 1, placed under the condition of -14°C Freeze for 4 h to obtain a uniform and transparent bamboo pulp cellulose solution;

[0028] 2) The bamboo pulp cellulose solution obtained in step 1) was thawed at room temperature, and the oxidant sodium periodate was added to shading oxidation for 3 h in a water bath at 50°C. The mass ratio of sodium periodate to mottled bamboo pulp board was 0.5:1, and the obtained Dialdehyde cellulose solution;

[0029] 3) Weigh 0.5 g of sericin with a molecular weight of 2k Da, ad...

Embodiment 3

[0032] 1) Grind 1 g of moso bamboo pulp with a plant grinder, filter through a 120-mesh sieve to obtain bamboo pulp powder with a particle size of 0.12 mm or less, add it to the mixed solution of sodium hydroxide and urea pre-frozen at 2 °C, and stir for 6 min to make it mix evenly, wherein the mass fractions of sodium hydroxide and urea are 8 wt% and 11 wt% respectively, the mass ratio of sodium hydroxide and urea mixed solution to moso bamboo pulp board is 40: 1, and placed under the condition of -14°C Freeze for 2 h to obtain a uniform and transparent bamboo pulp cellulose solution;

[0033] 2) The bamboo pulp cellulose solution obtained in step 1) was thawed at room temperature, and the oxidant sodium periodate was added to shading oxidation for 2 h in a water bath at 45°C, wherein the mass ratio of sodium periodate to moso bamboo pulp board was 0.65:1 to obtain Dialdehyde cellulose solution;

[0034]3) Weigh 1.5 g of sericin with a molecular weight of 5w Da, add it to 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com