Power battery module

A technology for power batteries and batteries, which is applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as leakage of phase change materials and potential safety hazards, improve temperature uniformity, protect single batteries, and maintain good The effect of the temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

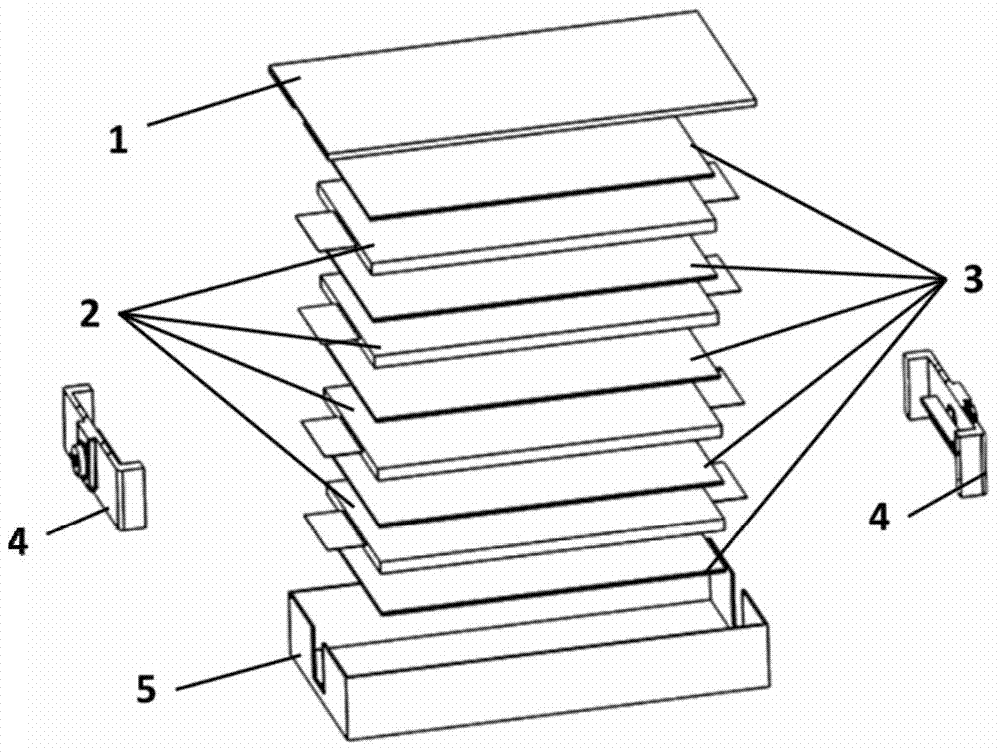

[0030] Such as figure 1 The power battery module shown is mainly composed of a module case cover 1 , a single battery 2 , a heat-absorbing gasket 3 , an electrical connector 4 , and a module case 5 . The single battery 2 and the heat-absorbing gasket 3 are stacked and arranged at intervals, and there is a single battery 2 between the two heat-absorbing gaskets 3 . Place the arranged single cells 2 and the heat-absorbing gasket 3 into the module case 5 together. One end of the two electrical connectors 4 is respectively connected to the two poles of the single battery 2, and the other end protrudes out of the module housing 5 to fix the electrical connector 4 and the housing 5. The outer surface of the electrical connector 4 is covered with insulating material layer. Cover the shell cover 1 of the module on the shell 5 and fix it, and the formed power battery module is as follows: figure 2 shown.

[0031] Among them, the single battery 2 is a rectangular lithium-ion batter...

Embodiment 2

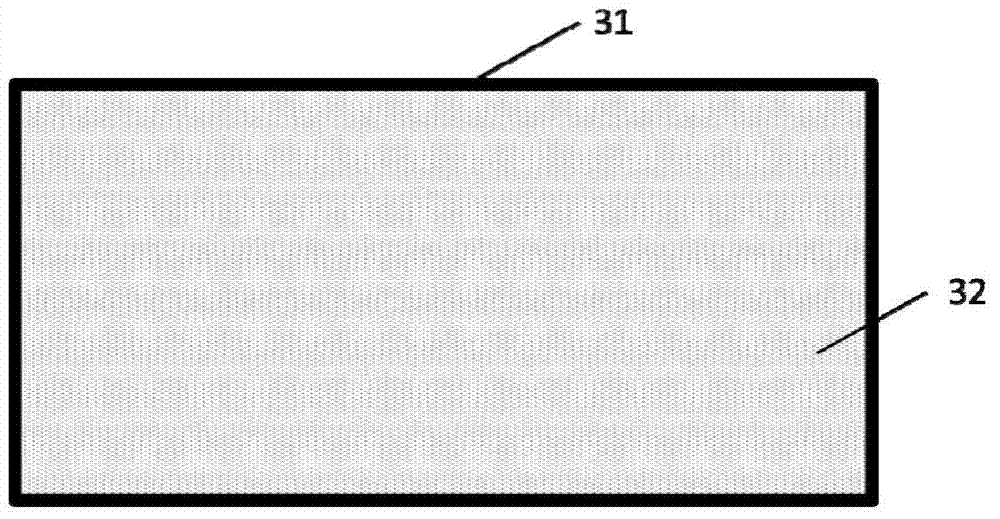

[0035] A power battery module, the structure of which is similar to that of Embodiment 1, the difference is that the single power battery 2 is a soft pack battery packaged in aluminum-plastic film, and the heat-absorbing gasket 3 is filled with a heat-conducting sealing coating layer 31. The change material 32 is formed by the aggregation of many phase change coated monomer particles 33 . Phase change coated monomer particles 33 such as Figure 4 As shown, it is composed of an outer polymer coating layer 311 and a phase change material core 312, the material of the polymer coating layer 311 is melamine resin, and the material of the phase change material core 312 is cetyl alcohol. The formed heat-absorbing gasket 3 has a thickness of 6.0 mm, the shape of the gasket is the same as that of the single battery 2 , and its size is slightly smaller than the bottom surface of the single power battery 2 . The outer surface of the single power battery 2 is coated with heat-conducting ...

Embodiment 3

[0038] A power battery module, the structure of which is similar to that of Embodiment 1, the difference is that the heat-absorbing gasket 3 is directly mixed and pressed into a sheet shape by covering the monomer particles 33 and the adhesive material 34, such as Figure 5 As shown, the phase change coated monomer particle 33 is composed of an outer melamine resin polymer coating layer 311 and a solid-liquid converted cetyl alcohol phase change material core 312, and the bonding material is silica gel.

[0039]This power battery module has the same advantages as Embodiment 1, and has enhanced safety and reliability. The heat-absorbing gasket 3 has a simple manufacturing process, is easy to form, and is soft in texture, which has a certain protective effect on the pouch battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com