Film packaging structure and organic light-emitting device with same

A thin-film packaging and thin-film technology, which is applied in organic light-emitting devices, organic light-emitting device structures, organic semiconductor devices, etc., can solve the problems of being easily affected by water vapor and oxygen, causing reactions, slow deposition speed, and shortening the service life of devices. Easy control of deposition conditions and thickness, good compactness and uniformity, weight and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

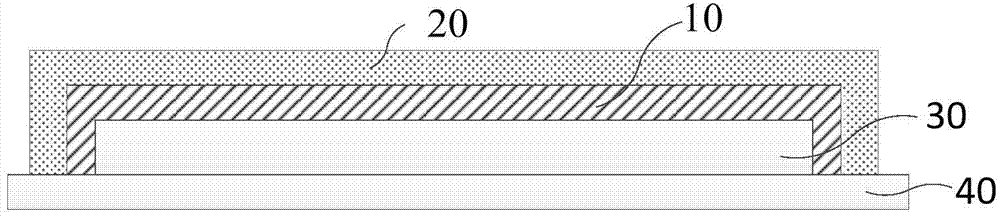

[0043] Example 1: Al 2 o 3 -ZrO 2 / SiN package structure

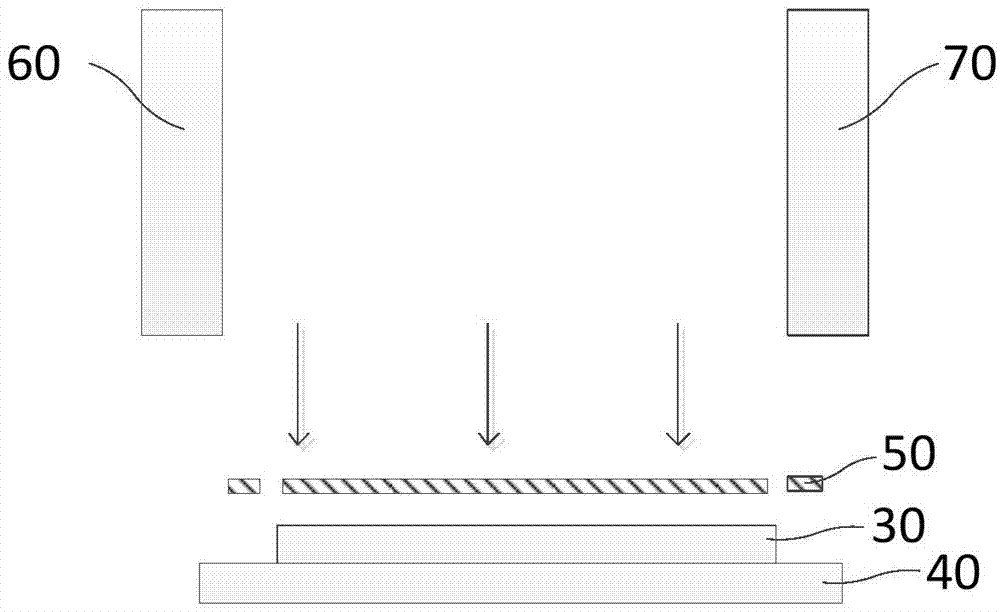

[0044] al 2 o 3 -ZrO 2 Formation of the mixed layer thin film 10: the device 30 takes an OLED unit prepared with electrodes and functional layers as an example, a mask 50 is placed on the device 30, and an amorphous Al 2 o 3 with crystalline ZrO 2 Target sputtering was performed as the first target 60 and the second target 70 respectively, and the sputtering power was set to 300W, the flow rate of argon gas was 30 sccm, the pressure was 1.0 mTorr, the flow rate of oxygen gas was 0.8 sccm, and the deposition time was 30 min. Al formed 2 o 3 -ZrO 2 The thickness of the mixed layer film 10 is about 100nm;

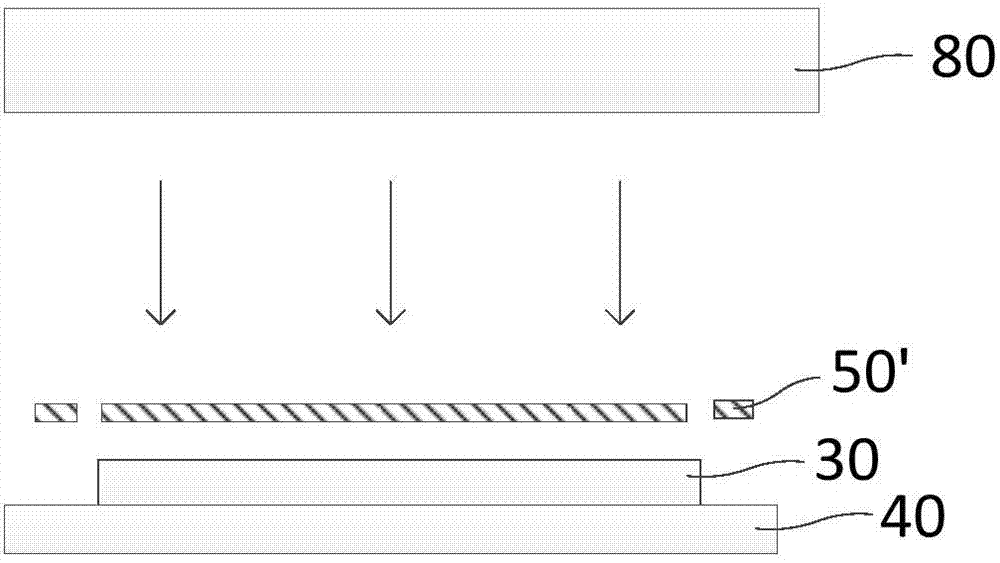

[0045] Formation of the SiN thin film: place the mask 50' above the device 30 on which the mixed layer thin film 10 is deposited, and perform magnetron sputtering with SiN as the third target 80, set the sputtering power to 500W, and the argon gas flow rate to 30 sccm, The pressure is 0.9mTorr, and the depo...

Embodiment 2

[0047] Example 2: Al 2 o 3 -ZnO / SiN package structure

[0048] al 2 o 3 -Formation of ZnO mixed layer thin film 10: device 30 takes an OLED unit prepared with electrodes and functional layers as an example, place mask 50 above device 30, and use amorphous Al 2 o 3 and crystalline ZnO as the first target 60 and the second target 70 respectively for target sputtering, set the sputtering power to 300W, the argon gas flow to 30sccm, the pressure to 1.0m Torr, the oxygen flow to 0.8sccm, and the deposition time for 30min. Al formed 2 o 3 - the thickness of the ZnO mixed layer thin film 10 is about 100nm;

[0049] Formation of the SiN thin film: place the mask 50' above the device 30 on which the mixed layer thin film 10 is deposited, and perform magnetron sputtering with SiN as the third target 80, set the sputtering power to 500W, and the argon gas flow rate to 30 sccm, The pressure is 0.9mTorr, and the deposition time is 30min. The formed SiN thin film 20 has a thicknes...

Embodiment 3

[0051] Example 3: Al 2 o 3 -MgO / Si 3 N 4 Package structure

[0052] al 2 o 3 -Formation of the MgO mixed layer thin film 10: the device 30 takes the OLED unit prepared with electrodes and functional layers as an example, the mask 50 is placed on the device 30, and the amorphous Al 2 o 3 and crystalline MgO respectively as the first target 60 and the second target 70 for target sputtering, set the sputtering power to 300W, the argon gas flow to 30sccm, the pressure to 1.0Torr, the oxygen flow to 0.8sccm, and the deposition time to be 30min. Al formed 2 o 3 - the thickness of the MgO mixed layer thin film 10 is about 110nm;

[0053] Si 3 N 4 Formation of the thin film: the mask 50' is placed over the device 30 deposited with the mixed layer thin film 10, with Si 3 N 4 Magnetron sputtering is performed for the third target 80 , the sputtering power is set to 500W, the argon gas flow rate is 30 sccm, the pressure is 0.9mTorr, and the deposition time is 30min. Formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com