Nickel-saving rare-earth/barium-containing biphase stainless steel alloy material and preparation method thereof

A technology of duplex stainless steel and alloy materials, applied in the field of duplex stainless steel, can solve the problems of difficulty in meeting high temperature and corrosive use conditions, increase production costs, etc., and achieve significant economic and social benefits, cost savings, and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the examples, but these examples do not constitute any limitation to the present invention.

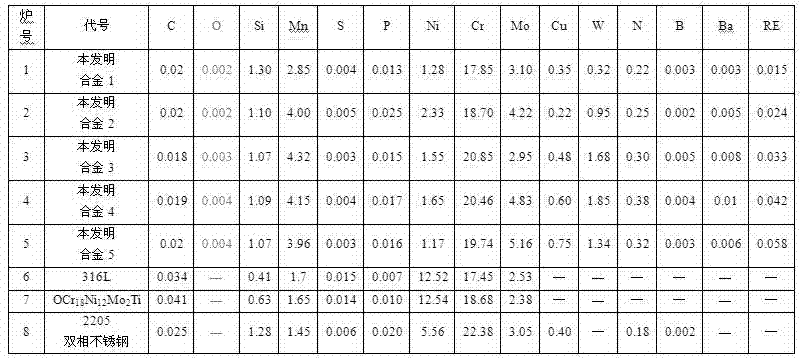

[0037] According to the chemical composition range set by the present invention, 5 furnaces of steel were smelted in a vacuum induction furnace, and aluminum was used for final deoxidation before tapping, and lanthanum-cerium mixed rare earth RE (lanthanum-cerium mixed rare earth, La≦51 %, Ce≦42%, also containing one or more of praseodymium, neodymium, promethium, samarium rare earth elements, rare earth content≧99.7%) and silicon-barium alloy, and then tapped and cast into ingots; steel ingots are forged into 20×50× For a 200mm slab, the forging temperature is 980-1300°C; the final chemical composition of the 5 furnace steel is as follows figure 1 shown in the list.

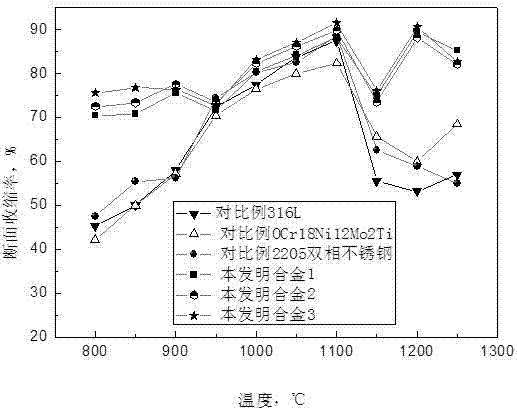

[0038] The mechanical performance samples of the alloy forged, the samples used for corrosion tests and the industrial coupons are direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com