Wear-resistant and anti-corrosion steel plate for shelf platform and preparation method thereof

A technology of anti-corrosion and steel plate, applied in the field of special wear-resistant and anti-corrosion steel plate for shelf platform and its preparation, which can solve the problems of increased storage cost, damage of storage equipment, corrosion of column and load plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

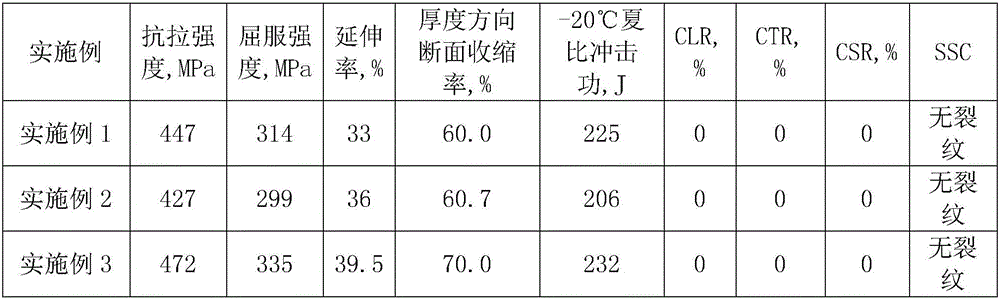

Examples

Embodiment 1

[0094] This embodiment is a special wear-resistant and anti-corrosion steel plate for shelf platforms. The composition and mass percentage of the steel plate are: C: 0.28%, Mn: 0.45%, Si: 0.09%, P: 0.006%, S≤0.004%, V : 0.07%, Ti: 0.08-0.12%, Al: 0.10%, N≤0.006%, Cu: 0.012%, Cr: 0.4%, Mo: 0.33%, rare earth trace elements: 0.015%, the balance is Fe and unavoidable impurities;

[0095] The chemical composition mass percentage of the rare earth trace elements is: Nd: 8%, Ce: 11%, Er: 3%, Pr: 2%, Pm: 1%, and the balance is La;

[0096] The first phase in the steel plate is ferrite, the second phase is pearlite, the volume percentage of the second phase from the surface to 1 / 4 thickness is 2.7%, and the volume percentage of the second phase from 1 / 4 thickness to the center is 7.0%, And there is no band structure; the average grain diameter of ferrite from the surface to 1 / 4 thickness of the steel plate is 3.2 μm, the average diameter of pearlite clusters is 5.2 μm, and the average...

Embodiment 2

[0116] The wear-resistant and anti-corrosion steel plate dedicated to the shelf platform in this embodiment has the composition and mass percentage of the steel plate: C: 0.29%, Mn: 0.46%, Si: 0.10%, P: 0.007%, S≤0.004%, V: 0.08 %, Ti: 0.10%, Al: 0.11%, N≤0.006%, Cu: 0.013%, Cr: 0.5%, Mo: 0.35%, rare earth trace elements: 0.022%, and the balance is Fe and unavoidable impurities;

[0117] The chemical composition mass percentage of the rare earth trace elements is: Nd: 10%, Ce: 15%, Er: 4%, Pr: 4%, Pm: 2%, Dy: 3%, and the balance is La;

[0118] The first phase in the steel plate is ferrite, the second phase is pearlite, the volume percentage of the second phase from the surface to 1 / 4 thickness is 2.8%, and the volume percentage of the second phase from 1 / 4 thickness to the center is 7.4%, And there is no band structure; the average grain diameter of ferrite from the surface to 1 / 4 thickness of the steel plate is 3.3 μm, the average diameter of pearlite clusters is 5.4 μm, and...

Embodiment 3

[0137] The wear-resistant and anti-corrosion steel plate dedicated to the shelf platform in this embodiment has the composition and mass percentage of the steel plate: C: 0.31%, Mn: 0.47%, Si: 0.12%, P: 0.008%, S≤0.004%, V: 0.09 %, Ti: 0.12%, Al: 0.13%, N≤0.006%, Cu: 0.015%, Cr: 0.6%, Mo: 0.36%, rare earth trace elements: 0.032%, and the balance is Fe and unavoidable impurities;

[0138] The chemical composition mass percentage of the rare earth trace elements is: Nd: 12%, Ce: 16%, Er: 5%, Pr: 6%, Pm: 4%, Dy: 5%, and the balance is La;

[0139] The first phase in the steel plate is ferrite, the second phase is pearlite, the volume percentage of the second phase from the surface to 1 / 4 thickness is 2.9%, and the volume percentage of the second phase from 1 / 4 thickness to the center is 7.5%, And there is no band structure; the average grain diameter of ferrite from the surface to 1 / 4 thickness of the steel plate is 3.4 μm, the average diameter of pearlite clusters is 5.6 μm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com