Metal nanowire network/mesoporous silica core-shell structure catalyst preparation method

A technology of mesoporous silica and core-shell structure, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve complex preparation steps and difficult large-scale Commercial synthesis and other issues, to achieve the effect of simple operation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Dissolve 145.78mg of cetyltrimethylammonium bromide in 10mL of chloroform, then add 10mL of 20mmol / L K 2 PtCl 4 Aqueous solution, stirring and reacting at 25°C for 2 hours, standing still, separating and removing the upper aqueous phase, then adding 90mL of deionized water, and adding 10mL of 300mmol / L NaBH at 1600 rpm 4 Aqueous solution, reacted for 5 minutes, finally added ammonia water to adjust the pH value to 10, and 144 μL tetraethyl orthosilicate, reacted for 1 hour at 35 ° C, transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, in Crystallize at 100°C for 72 hours, wash, dry and calcinate to obtain a metal nanowire network / mesoporous silica core-shell structure catalyst.

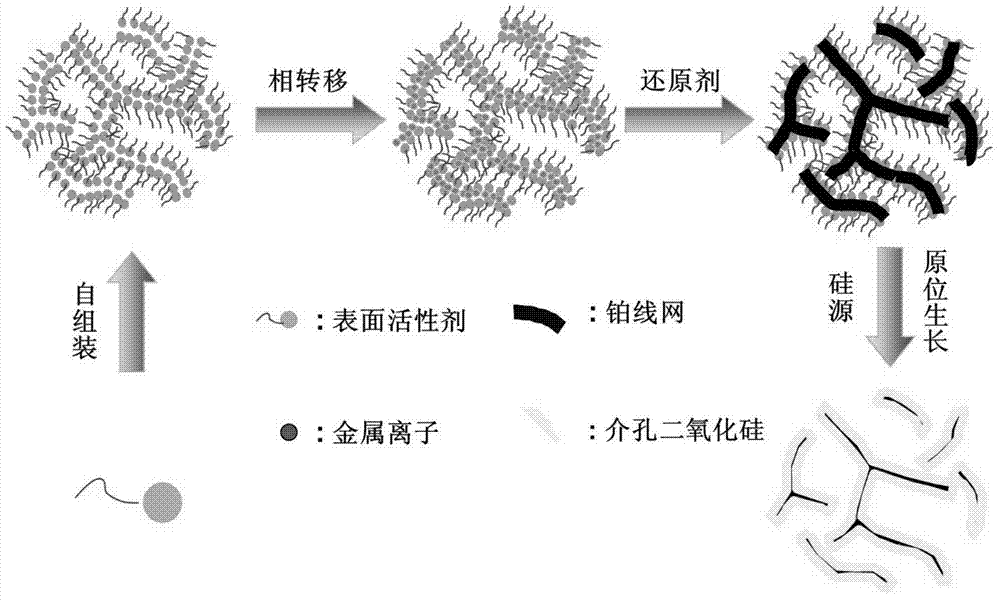

[0041] The schematic diagram of this method is shown in figure 1 shown.

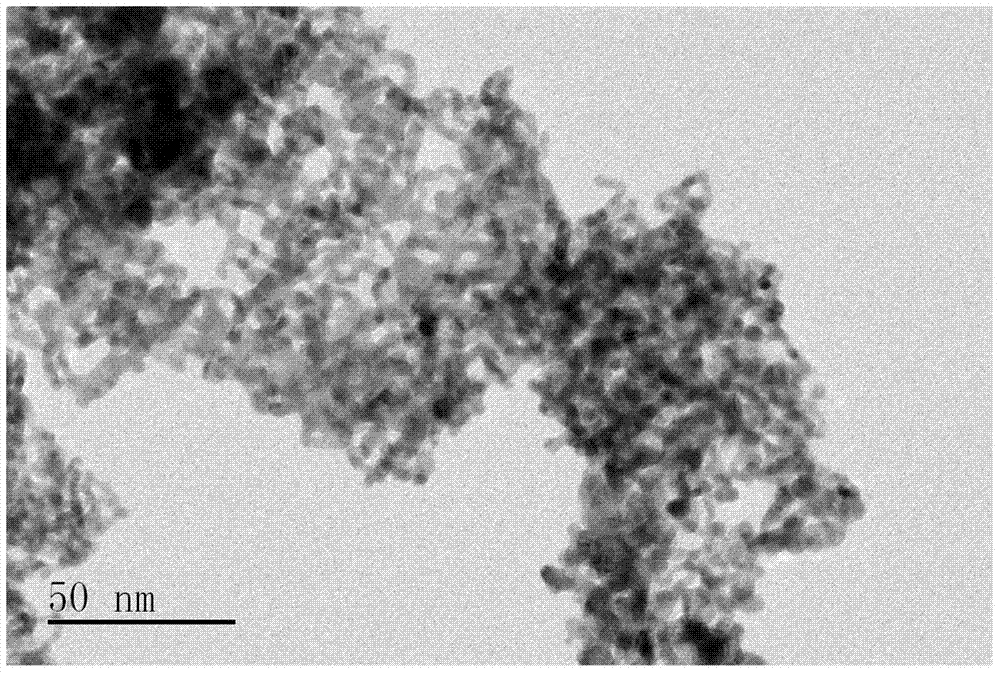

[0042] Such as figure 2 , compared with the sample without ethyl orthosilicate, the diameter of the wire mesh structure increased from 2nm to 3nm, indicating that a 0.5nm thick silico...

Embodiment 2

[0046] Embodiment 2: surfactant kind

[0047] Dissolve 115.35 mg of sodium cetyl sulfonate in 10 mL of chloroform, and then add 10 mL of 20 mmol / L K 2 PtCl 4 Aqueous solution, stirring and reacting at 25°C for 2 hours, standing still, separating and removing the upper aqueous phase, then adding 90mL of deionized water, and adding 10mL of 300mmol / L NaBH at 1600 rpm 4 Aqueous solution, reacted for 5 minutes, finally added ammonia water to adjust the pH value to 10, and 144 μL tetraethyl orthosilicate, reacted for 1 hour at 35 ° C, transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, in Crystallize at 100°C for 72 hours, wash, dry and calcinate to obtain a metal nanowire network / mesoporous silica core-shell structure catalyst.

Embodiment 3

[0048] Embodiment 3: types of hydrophobic solvents

[0049] Dissolve 145.78mg of cetyltrimethylammonium bromide in 10mL of toluene, then add 10mL of 20mmol / L K 2 PtCl 4 Aqueous solution, stirring and reacting at 25°C for 2 hours, standing still, separating and removing the upper aqueous phase, then adding 90mL of deionized water, and adding 10mL of 300mmol / L NaBH at 1600 rpm 4 Aqueous solution, reacted for 5 minutes, finally added ammonia water to adjust the pH value to 10, and 144 μL tetraethyl orthosilicate, reacted for 1 hour at 35 ° C, transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, in Crystallize at 100°C for 72 hours, wash, dry and calcinate to obtain a metal nanowire network / mesoporous silica core-shell structure catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com