Bi/Aurivillius type oxide composite material as well as preparation method and application thereof

A technology of composite materials and oxides, which is applied in the field of materials, can solve problems such as uneven distribution of metals and affect material properties, and achieve the effects of improving photocatalytic efficiency, inhibiting recombination, and expanding the range of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

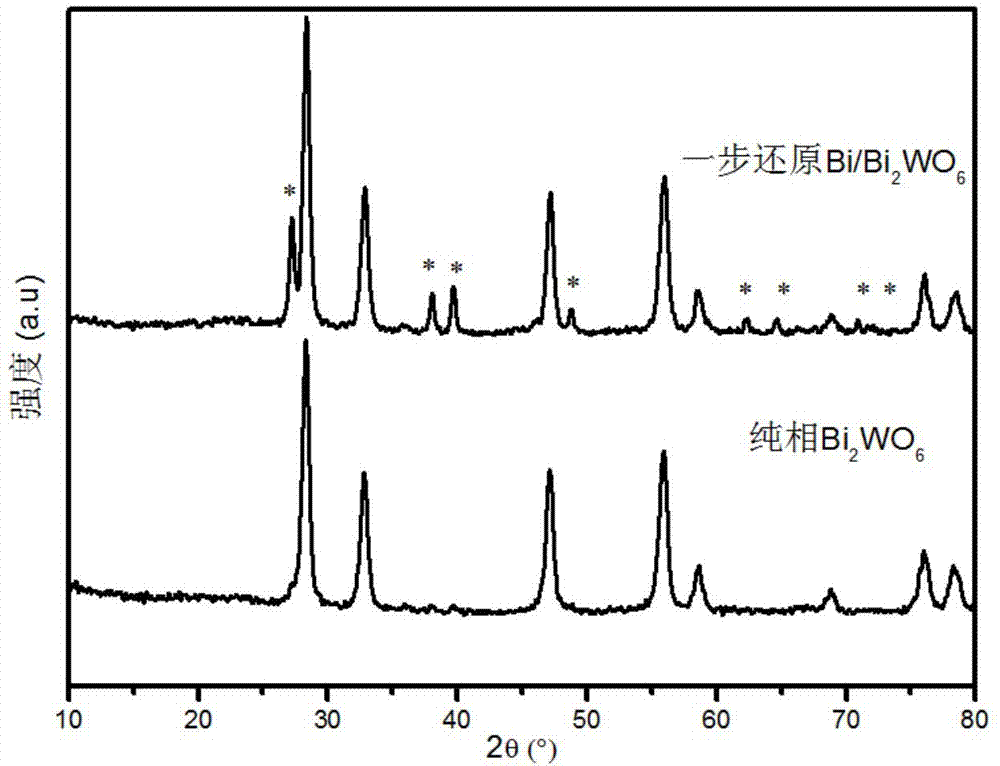

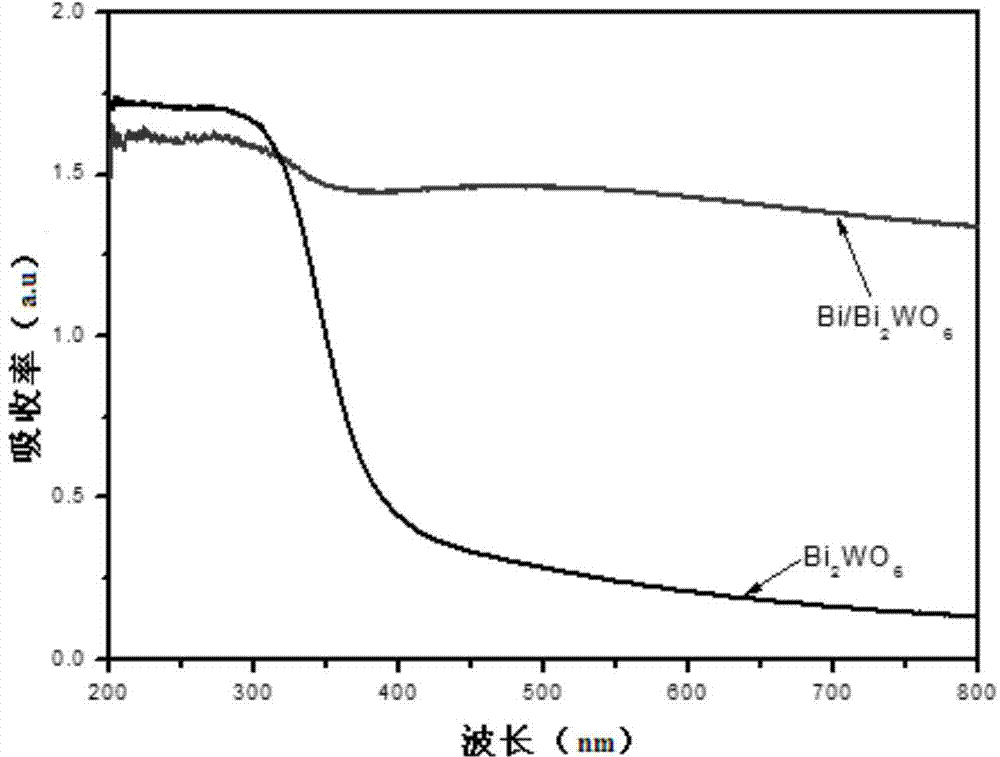

[0033] One-step solvothermal in situ reduction of Bi / Bi 2 WO 6 Composite material, the preparation method is as follows: 1.6866g Bi(NO 3 ) 3 ·5H 2 O and 0.5740 g Na 2 WO 4 2H 2 O was dissolved in 5mL of ethylene glycol respectively, after fully stirring and dissolving, the Na 2 WO 4 The solution was slowly added dropwise to Bi(NO 3 ) 3 Add 20mL ethylene glycol dilution solution to the solution, mix evenly and transfer to a 50mL hydrothermal reaction kettle, react at 220°C for 20h, wait for the reaction kettle to cool down to room temperature naturally, centrifuge and wash, dry at 80°C, grind , get Bi / Bi 2 WO 6 composite material.

[0034] In order to compare the photocatalytic experiments, the pure phase Bi 2 WO 6 powder.

[0035] In addition, in order to compare the photocatalytic experiment, take 100mg of the above pure phase Bi 2 WO 6 The powder was dissolved in Bi(NO 3 ) 3 In the ethylene glycol solution, use excess NaBH 4 Bi in ethylene glycol solution...

Embodiment 2

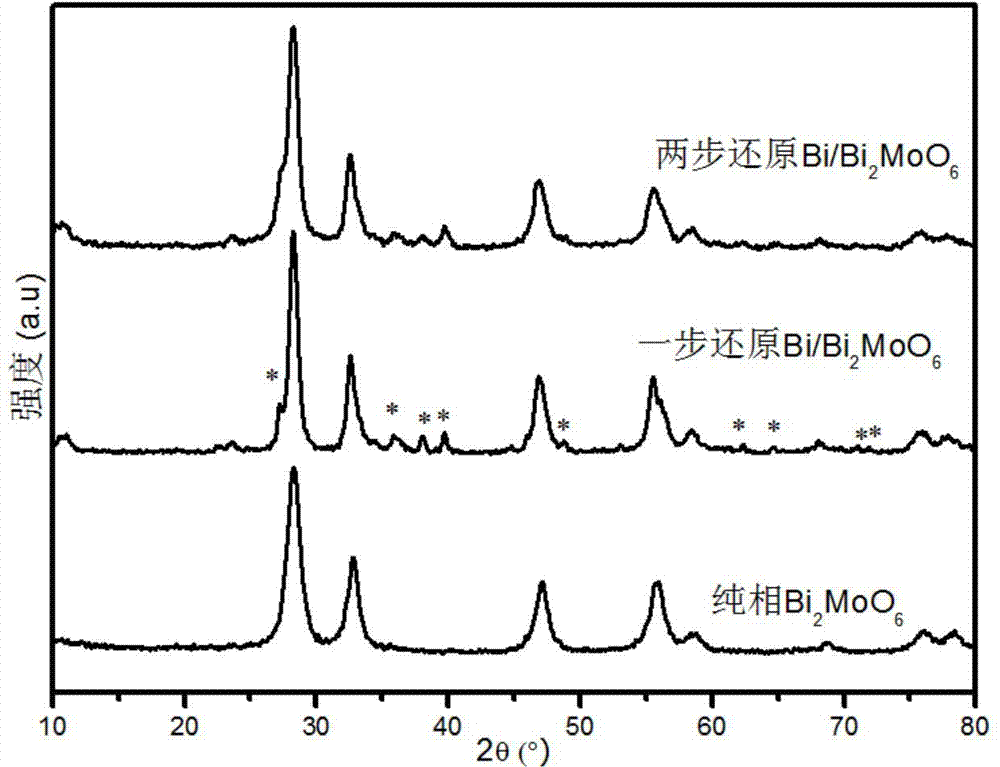

[0040] One-step solvothermal in situ reduction of Bi / Bi 2 MoO 6 Composite material, the preparation method is as follows: 1.6866g Bi(NO 3 ) 3 ·5H 2 O and 0.4217g Na 2 MoO 4 2H 2 O was respectively dissolved in 5mL of ethylene glycol, and after fully stirring until all the solids were dissolved, the Na 2 MoO 4 The solution was slowly added dropwise to Bi(NO 3 ) 3 Add 20mL ethylene glycol dilution solution to the solution, stir well and transfer to 50mL hydrothermal reaction kettle, react at 170°C for 20h respectively, wait for the reaction kettle to cool down to room temperature naturally, centrifuge and wash, and dry at 80°C 10h, grind to get Bi / Bi 2 MoO 6 composite material.

[0041] In order to compare the photocatalytic experiments, the pure phase Bi 2 MoO 6 powder.

[0042] In addition, in order to compare the photocatalytic experiments, 100 mg of pure phase Bi 2 MoO 6 The powder was dissolved in Bi(NO 3 ) 3 In the ethylene glycol solution, use excess Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com