Vertical structure algan/gan HEMT device and fabrication method thereof

A vertical structure and device technology, applied in the field of microelectronics, can solve problems such as serious current collapse effect, lattice damage, and complexity, and achieve the effects of eliminating the influence of two-dimensional electron gas concentration, enhancing withstand voltage characteristics, and improving withstand voltage characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

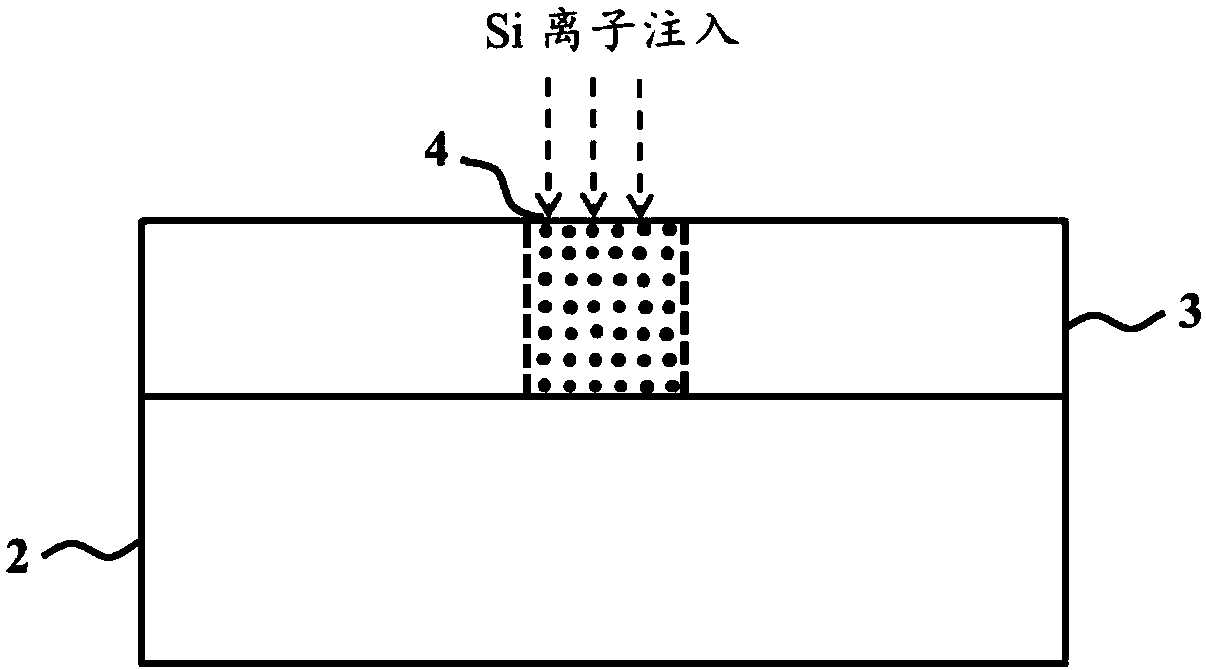

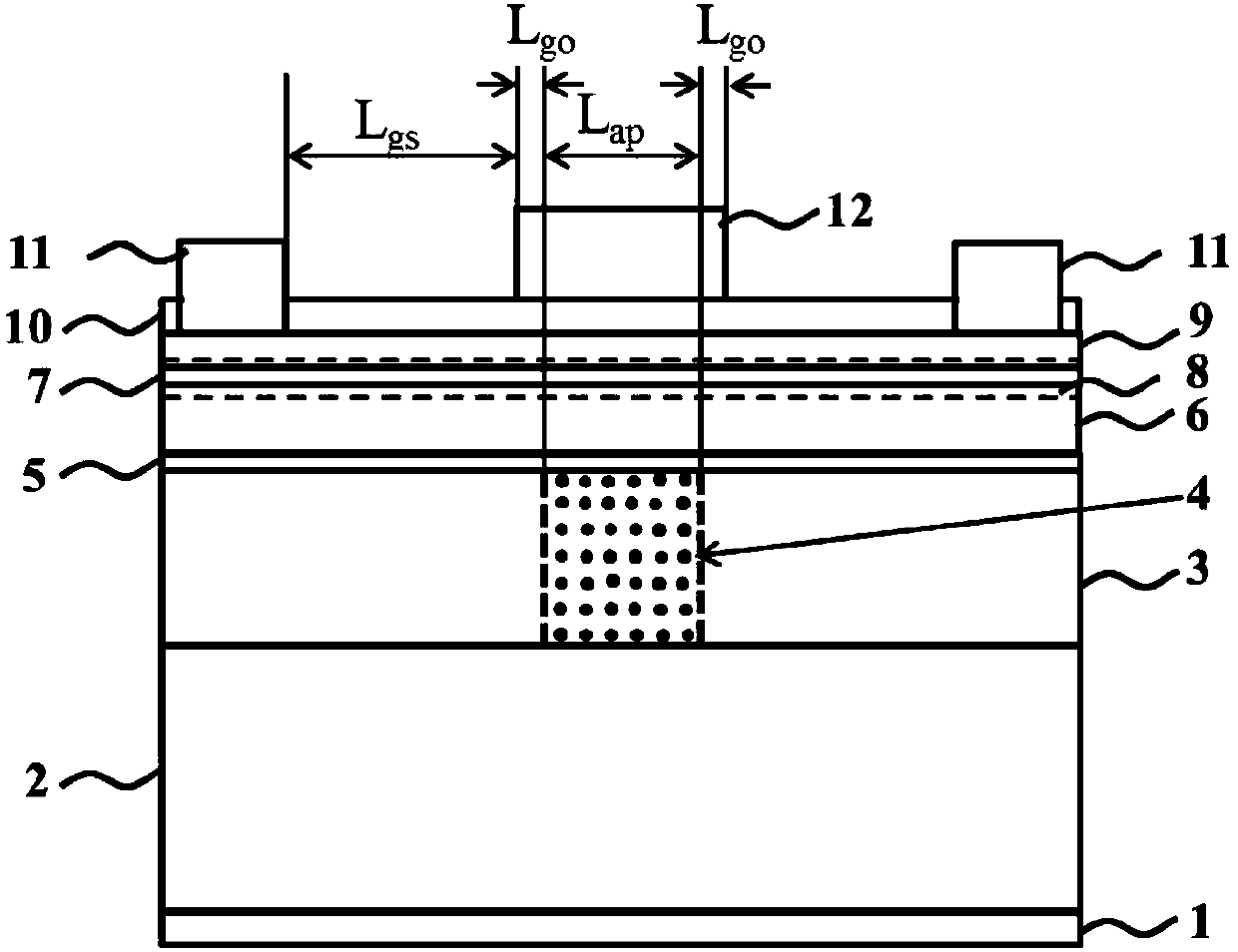

[0053] Example 1 see Figure 4 Shown is a flow chart of a typical manufacturing process of the device of the present invention, but the present invention is not limited to the accompanying drawings and the content described in the following examples, which only use high-resistance GaN as a current blocking layer to achieve conduction and conduction through Si ion implantation. Typical exemplary embodiment of the vertical structure of the hole.

[0054] This embodiment relates to a vertical structure AlGaN / GaN HEMT device using high-resistance GaN as a CBL to form conducting vias through Si ion implantation, which includes the following steps:

[0055] (1) First, use MOCVD to epitaxially grow a high-resistance GaN layer 2 in the range of hundreds of nanometers to several micrometers. After taking it out of the MOCVD chamber, use an organic solution to clean it and purging it with high-purity nitrogen. See the appendix figure 1 .

[0056] (2) Perform photolithographic developm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com