Coal-fired boiler coal quality on-line soft measurement method and system

A technology for coal-fired boilers and soft measurement, which is applied in the intersection of power equipment and information technology, and can solve the problems of large errors, difficulty in ensuring result accuracy, and large fitting errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

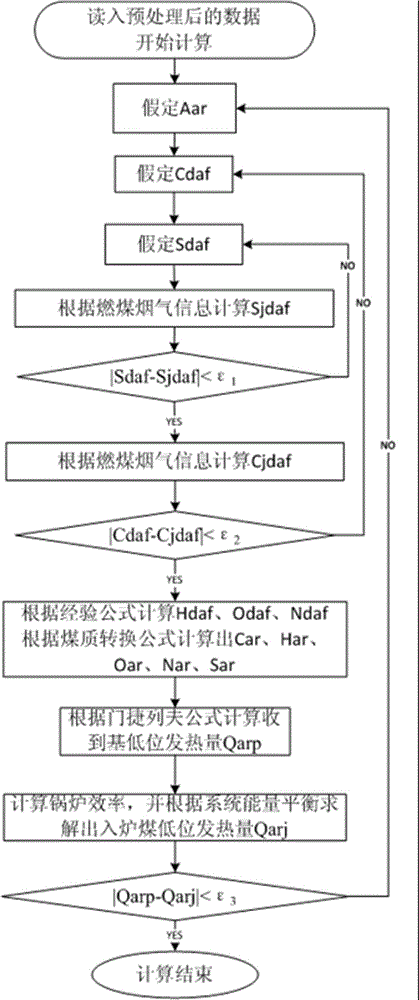

[0088] figure 1 It is a flow chart of the online soft-sensing method for coal quality of a coal-fired boiler of the present invention.

[0089] Such as figure 1 Shown, the coal-fired boiler coal quality online soft measurement method of the present invention.

[0090] The data involved in this coal-fired boiler online soft-sensing method, that is, boiler flue gas data and unit operating status data include:

[0091] Mar: the average moisture content of coal into the furnace, unit %

[0092] Grml: total amount of coal into the furnace, unit kg

[0093] gammaO 2 : The average value of oxygen at the outlet of the air preheater, unit %

[0094] gamma SO 2 : SO in flue gas 2 content, unit mg / m 3

[0095] tG: exhaust gas temperature, unit ℃

[0096] tA: ambient temperature, unit ℃

[0097] Dgq: the actual evaporation capacity of the boiler, unit t / h

[0098] Grc: reheat steam flow rate, unit kg / h

[0099] Gms: feed water flow, unit kg / h

[0100] Grs: desuperheating wat...

Embodiment 2

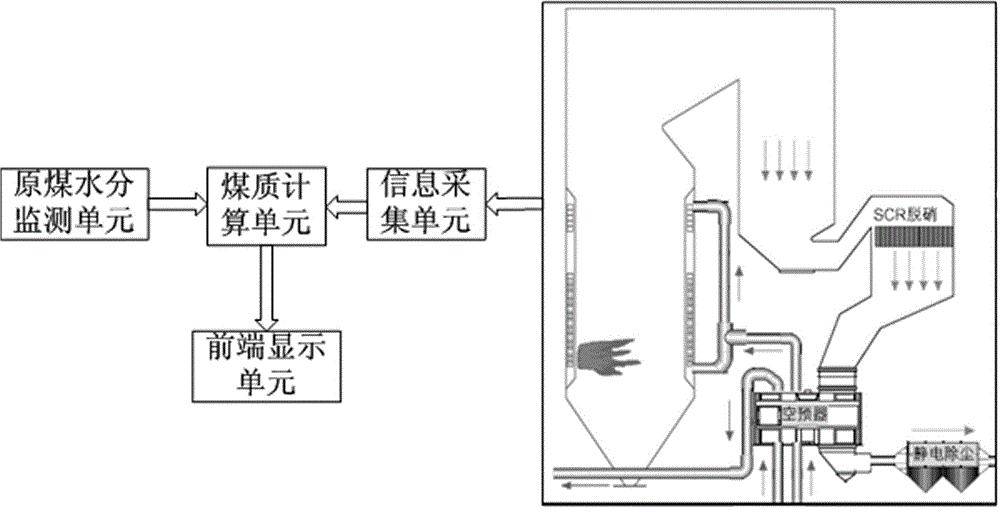

[0194] figure 2 It is a functional block diagram of the measurement system of the present invention.

[0195] On the basis of Embodiment 1, the present invention also provides an online soft measurement system for coal quality of a coal-fired boiler, including:

[0196] The raw coal moisture monitoring unit is used to collect the raw coal moisture.

[0197] Specifically, the raw coal moisture monitoring unit is based on the moisture measurement theory of the microwave attenuation method. When measuring the water content of raw coal, the microwave attenuation is accurately measured, the relationship between the microwave attenuation and the water content is found, and the measurement calibration curve is obtained. The moisture monitoring device emits microwaves from above the material and receives microwaves below the conveyor belt. The measuring system determines the moisture content of the material on the conveyor belt by measuring the phase shift and energy attenuation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com