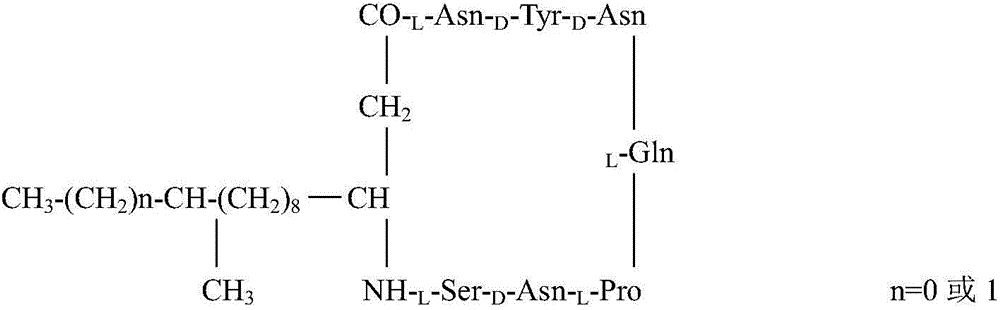

High-efficiency preparation method of Iturin A and homologue of Iturin A

A technology of iturin and its homologues, applied in the field of microorganisms, can solve the problems of increasing the difficulty of fermentation process, high production cost, and difficulty in realizing industrialized production, and achieves the effects of reducing foam, increasing yield and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

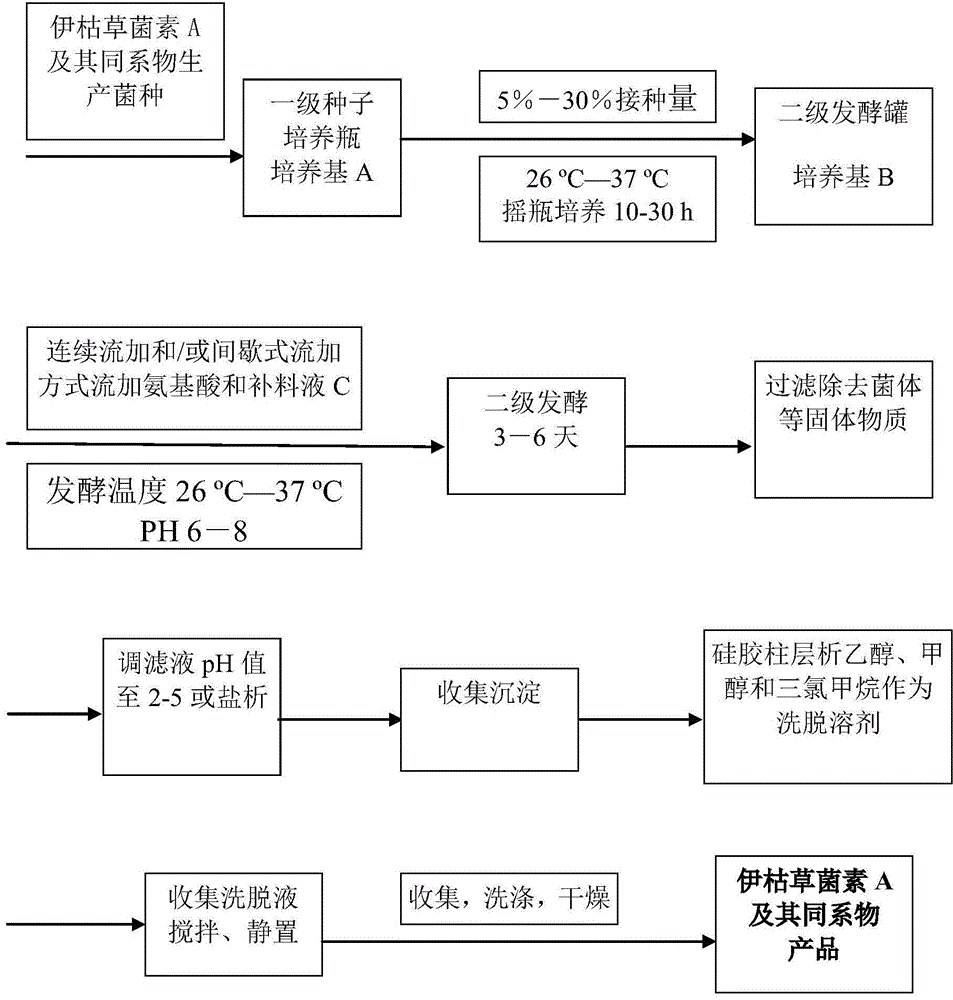

Method used

Image

Examples

Embodiment 1

[0070] Use 12 1000mL triangular flasks, each containing 300mL medium A (soluble starch 1.0% glycerin 0.6%, glucose 5.0%, peptone 1.0%, yeast extract 0.5%, magnesium sulfate 0.5%, potassium dihydrogen phosphate 0.5%, sodium chloride 0.3%), sterilized at 120°C for 30 minutes, inoculated with activated Bacillus subtilis (Bacillus subtilis) ZK-H28 bacterial solution after cooling, placed at 30°C, and shaken the flask for 18 hours. Inoculate the cultured strain solution into a 100L fermenter with 50L sterilized medium B (medium B: corn flour 2.0%, maltose 1.0%, sucrose 0.5%, glycerol 0.5%, glucose 1.0%, peptone 1.0%, soybean flour hydrolyzate 5.0%, yeast extract 0.5%, fish bone meal 1.0%, potassium dihydrogen phosphate 0.5%, ammonium nitrate 0.5%, magnesium sulfate 0.2%, sodium chloride 0.3% ), at a temperature of 28°C-30°C, after aeration and stirring for 5-15 hours, the amino acid feeding solution (g / mL) (Lys1.0x10 -5 , Ser1.0x10 -4 , Gln2.0x10 -4 ,Asp5.0x10 -4 , Asn1.0x10 -...

Embodiment 2

[0075] Use 10 1000mL triangular flasks, each containing 300mL medium A (soluble starch 2.0%, glycerin 0.5%, glucose 5.0%, peptone 3.0%, yeast extract 0.3%, magnesium sulfate 0.6%, potassium dihydrogen phosphate 0.6%, chloride Sodium 0.4%), sterilized at 120°C for 30 minutes, inoculated with activated Bacillus subtilis (Bacillus subtilis) ZK-H6 (CGMCC No.2897) bacteria solution after cooling, placed at 30°C, shake flask cultured for 18 hours . Inoculate the cultured strain solution into a 100L fermenter with 50L sterilized medium B (medium B: corn flour 2.0%, maltose 1.0%, sucrose 0.5%, glycerol 0.5% %, glucose 1.0%, peptone 1.0%, soybean flour hydrolyzate 5.0%, yeast extract 0.5%, fish bone meal 1.0%, potassium dihydrogen phosphate 0.5%, ammonium nitrate 0.5%, magnesium sulfate 0.2%, sodium chloride 0.3%) , at a temperature of 28°C-30°C, after aeration and stirring for 5-15 hours, the amino acid feeding solution (g / mL) (Lys 1.0x10 -5 , Ser 1.0x10 -4 , Gln 2.0x10 -4 , Asp 5...

Embodiment 3

[0080] Use 12 1000mL triangular flasks, each containing 300mL medium A (soluble starch 4.0%, glycerin 1.0%, glucose 3.0%, peptone 1.0%, yeast extract 0.5%, magnesium sulfate 0.5%, potassium dihydrogen phosphate 0.5%, chloride Sodium 0.3%), sterilized at 120°C for 30 minutes, inoculated with activated Bacillus subtilis ZK-H28 bacterial solution after cooling, placed at 30°C, and shaken the flask for 18 hours. Inoculate the cultured strain solution into a 100L fermenter with 50L sterilized medium B (medium B: 3.0% corn flour, 1.0% maltose, 1.5% sucrose, glucose 1.0%, peptone 2.0%, soybean flour hydrolyzate 4.0%, yeast extract 0.5%, fish bone meal 1.0%, potassium dihydrogen phosphate 0.5%, ammonium nitrate 0.5%, magnesium sulfate 0.2%, sodium chloride 0.3%), at 28 ℃-30℃, aeration and stirring for 3-15 hours after fermentation, add amino acid feeding solution (g / mL) intermittently (Lys 0.5x10 -5 , Ser 1.5x10 -4 , Gln5.0x10 -5 , Asp 5.0x10 -4 , Asn 2.0x10 -4 , Glu 7.0x10 -5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com