Preparation method of optical wear-resistant hardening coating composition and hard coated film thereof

A composition and compound technology, applied in optics, optical components, polyester coatings, etc., can solve the problems of increasing production man-hours and energy consumption, increasing product costs, reducing finished product yields, etc., to reduce frequent operations, reduce man-hours and The effect of energy consumption and product yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

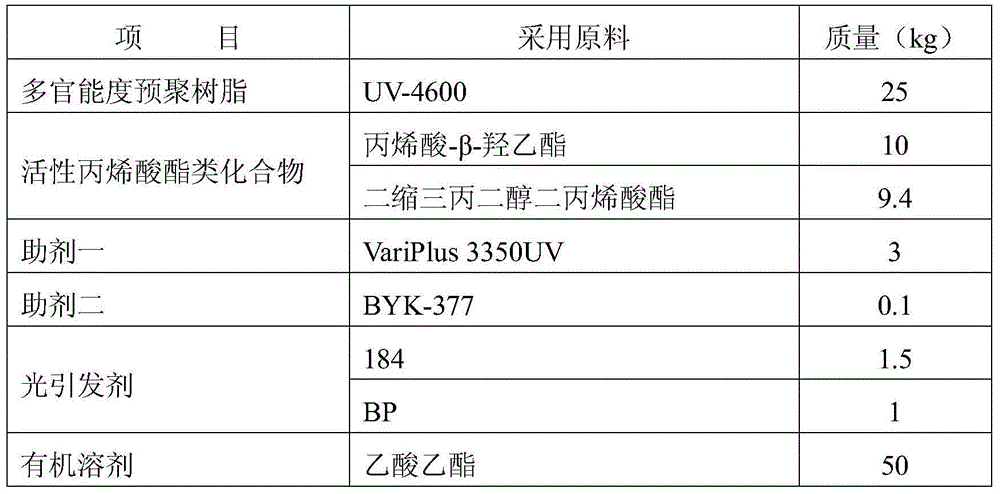

[0039] ●Formulation of optical wear-resistant hardening coating composition

[0040]

[0041] ●Preparation of optical wear-resistant hardening coating composition

[0042] Under the conditions of avoiding sunlight, especially ultraviolet light irradiation, and air humidity less than 60%, and temperature at 20-30°C, add the above-mentioned components into ethyl acetate solvent in sequence, and stir thoroughly for at least 30 minutes until all components are homogeneous. Completely dissolve, filter to remove impurities, and prepare an optical wear-resistant hardening coating composition, which is set aside.

[0043] ●Preparation of optical hardening film

[0044] The optical wear-resistant hardening coating composition prepared above is coated on one surface of the optical grade polyester base film by the gravure coating method, and is dried through an oven at a line speed of 25m / min. The temperature of the oven: 50°C in section I ; Section II 70°C; Section III 80°C; Sectio...

Embodiment 2

[0046] ●Formulation of optical wear-resistant hardening coating composition

[0047]

[0048] ●Preparation of optical wear-resistant hardening coating composition

[0049] Under the conditions of avoiding sunlight, especially ultraviolet light irradiation, and air humidity less than 60%, and temperature at 20-30°C, add the above-mentioned components into the mixed solvent of ethyl acetate and methyl ethyl ketone in sequence, and stir thoroughly for at least 30 minutes, Until all components are completely dissolved, impurities are removed by filtration to obtain an optical wear-resistant hardening coating composition for future use.

[0050] ●Preparation of optical hardening film

[0051] Coat the optical wear-resistant and hardening coating composition prepared above on one side of the optical grade polyester base film by gravure coating, and dry it through the oven at a line speed of 25m / min. ; Section II 80°C; Section III 95°C; Section IV 125°C; Section V 85°C to remove...

Embodiment 3

[0053] ●Formulation of optical wear-resistant hardening coating composition

[0054]

[0055]

[0056] ●Preparation of optical wear-resistant hardening coating composition

[0057] Under the conditions of avoiding sunlight, especially ultraviolet light irradiation, and air humidity less than 60%, and temperature at 20-30°C, add the above-mentioned components into the mixed solvent of isopropanol and methyl ethyl ketone in turn, and stir thoroughly for at least 30 minutes until All the components are completely dissolved, and the impurities are removed by filtration to obtain an optical wear-resistant hardening coating composition, which is ready for use.

[0058] ●Preparation of optical hardening film

[0059] Coat the optical wear-resistant and hardening coating composition formulated above on one side of the optical grade polyester base film by gravure coating, and dry it through the oven at a line speed of 20m / min. The temperature of the oven: Section I 60°C ; Secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com