A method of forming a semiconductor device

A semiconductor and device technology, applied in the field of fully isolated back-illuminated image sensor and its manufacturing, can solve the problem of high cost, achieve the effect of reducing on-resistance, improving production efficiency, and maintaining stable on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

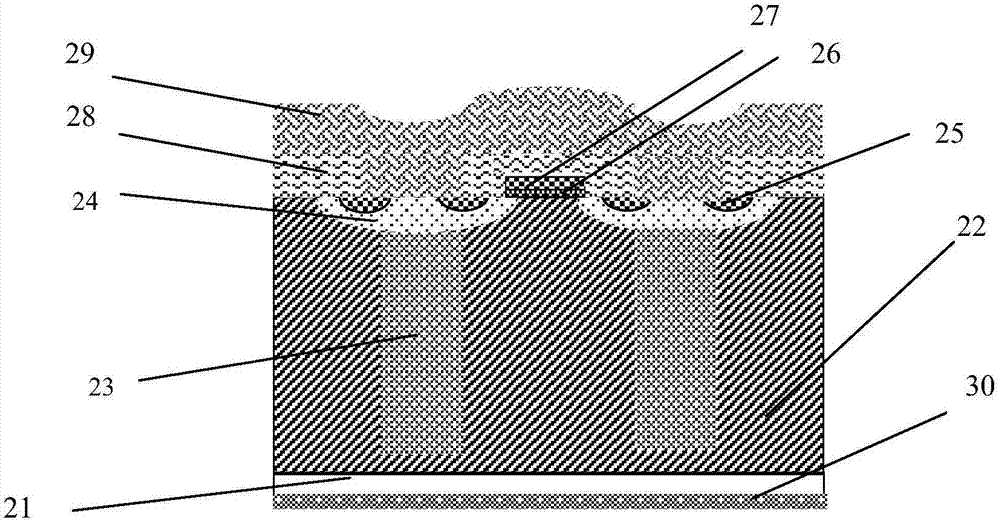

[0033] Such as Figure 2-Figure 12 As shown, a method for forming a semiconductor device of the present invention specifically includes the following steps:

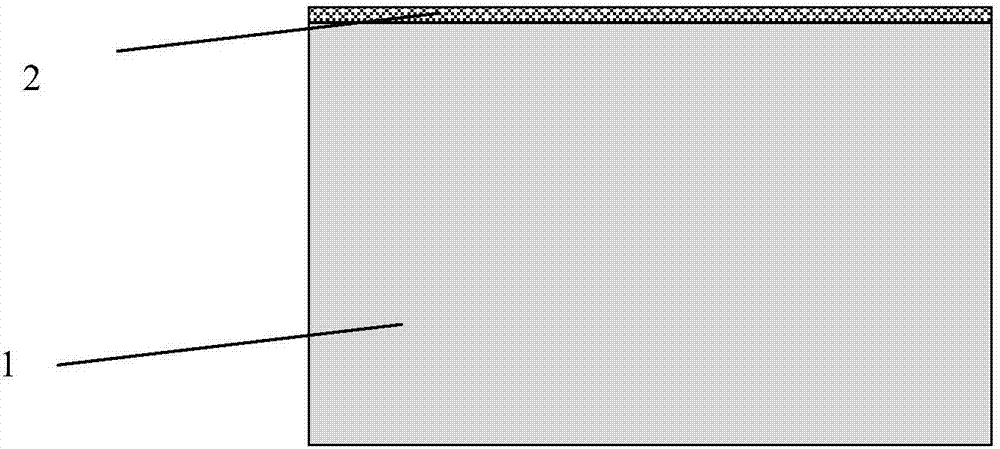

[0034] 1) Grow dielectric layer 2 on semiconductor silicon substrate 1, semiconductor silicon substrate 1 can be N-type or P-type, doping concentration is 1E13-1E17cm -3 ; The dielectric layer 2 is at least one of silicon oxide, silicon nitride, and silicon oxynitride, with a thickness of 0.1 μm-2 μm (see figure 2 ).

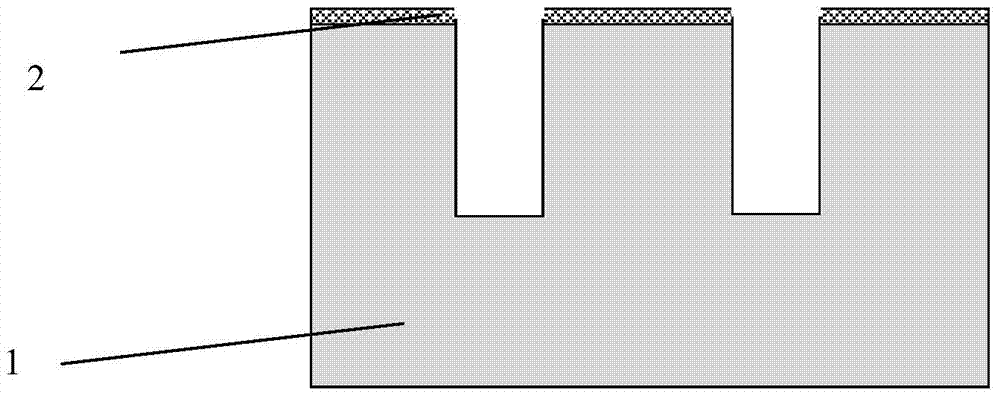

[0035] 2) Etching deep trenches on the semiconductor silicon substrate 1, the deep trenches have a width of 1-10 μm, a depth of 10-80 μm, and a trench spacing of 2-15 μm (see image 3 ); and the pre-measured doping concentration of the semiconductor silicon substrate 1 makes the depth of the deep trench positively correspond to the doping concentration of the semiconductor silicon substrate 1, that is, the breakdown voltage of the device is preset, when the semiconductor silicon substrate When the dopi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com