Glipizide oral instant film and preparation method thereof

A technology of oral instant film and oral instant film agent, applied in the field of glipizide oral instant film and preparation thereof, can solve the problems of difficulty in dispersion, affecting the content uniformity of the main drug, easy to float above the solution, etc., and achieves portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

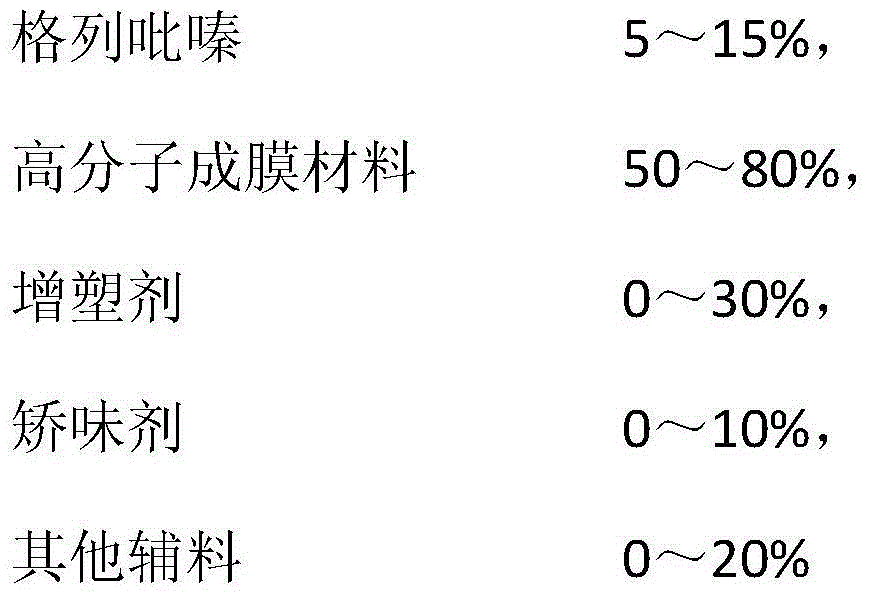

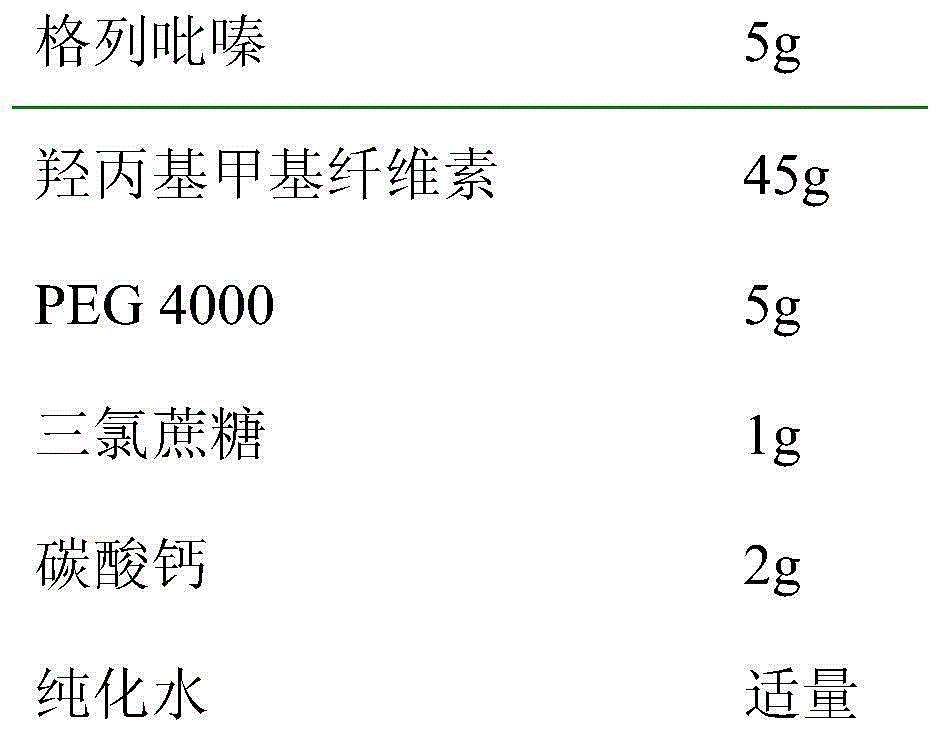

[0034] Each tablet contains 5mg of glipizide, and the composition of 1000 tablets of glipizide oral instant film is:

[0035]

[0036] The specific operation process is as follows:

[0037] The glipizide is pulverized by jet milling, the polyethylene glycol 4000 and the glipizide are uniformly combined, hot-melt extruded to make a solid dispersion, pulverized, and sieved. Weigh hydroxypropyl methylcellulose, add water and stir to swell and dissolve to obtain solution A; then weigh the pulverized solid dispersion and sucralose, add water and stir to dissolve to obtain solution B; add the above solution B to solution A, stir After uniformity, add calcium carbonate, stir and mix evenly, remove air bubbles, apply film, dry, cut into 3cm×2cm, and obtain glipizide oral instant film.

[0038] The film has a rough appearance, high hardness, obvious graininess to the touch, poor flexibility, slow dissolution at the entrance, low viscosity, and a melting time limit of 50 seconds.

example 2

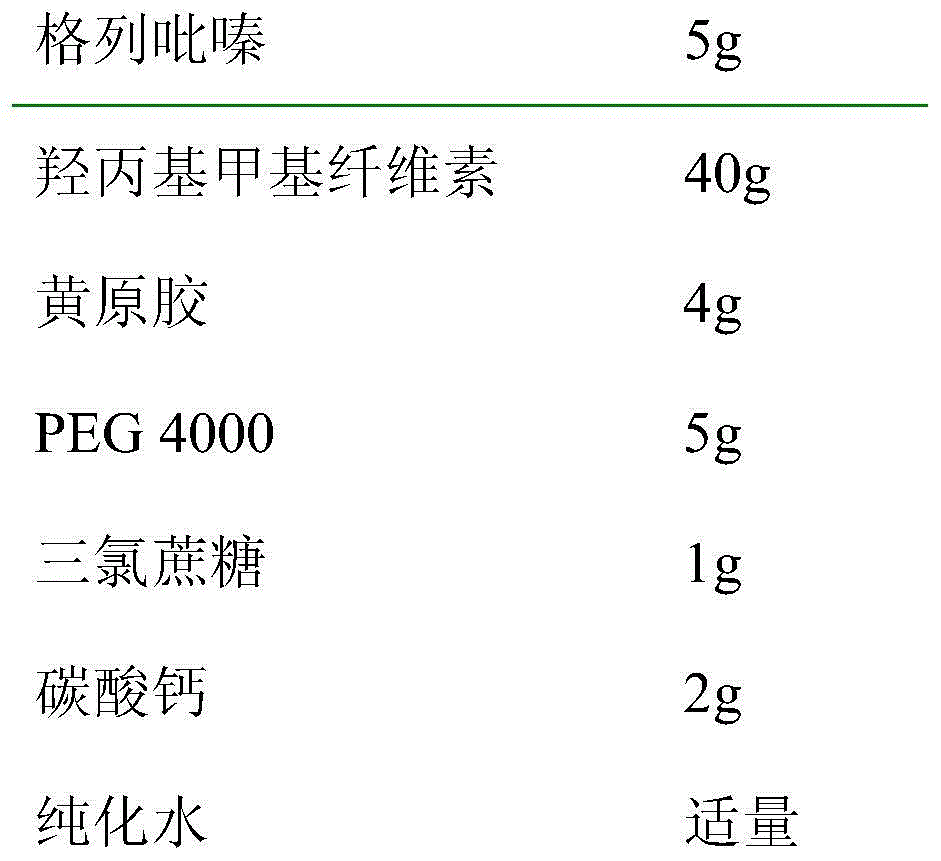

[0040] Each tablet contains 5mg of glipizide, and the composition of 1000 tablets of glipizide oral instant film is:

[0041]

[0042] The specific operation process is as follows:

[0043] The glipizide is pulverized by jet milling, the polyethylene glycol 4000 and the glipizide are uniformly combined, hot-melt extruded to make a solid dispersion, pulverized, and sieved. Weigh hydroxypropyl methylcellulose, xanthan gum, add water, stir and dissolve to obtain solution A; then weigh the pulverized solid dispersion, sucralose, add water and stir to dissolve to obtain solution B; add the above solution B to the solution In A, stir evenly, add calcium carbonate, mix evenly, remove air bubbles, apply a film, dry, cut into 3cm×2cm, and obtain glipizide oral instant film.

[0044] The film has a good appearance, translucent, grainy to the touch, moderate flexibility, improved dissolution rate at the entrance, increased viscosity, and a melting time limit of 35s.

example 3

[0046] Each tablet contains 5mg of glipizide, and the composition of 1000 tablets of glipizide oral instant film is:

[0047]

[0048]

[0049] The specific operation process is as follows:

[0050] The glipizide is pulverized by jet milling, the polyethylene glycol 4000 and the glipizide are uniformly combined, hot-melt extruded to make a solid dispersion, pulverized, and sieved. Weigh hydroxypropyl methylcellulose, xanthan gum, add water, stir, swell and dissolve to obtain solution A; then weigh the pulverized solid dispersion, sucralose, add water and stir to dissolve to obtain solution B; add the above solution B to solution A After stirring evenly, add calcium carbonate and colloidal silicon dioxide, mix evenly, remove air bubbles, apply a film, dry, cut into 3cm×2cm, and obtain the glipizide oral instant film.

[0051] The film has a good appearance, translucent, no grainy feeling, moderate flexibility, good dissolution at the entrance, moderate viscosity, and a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking force | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com