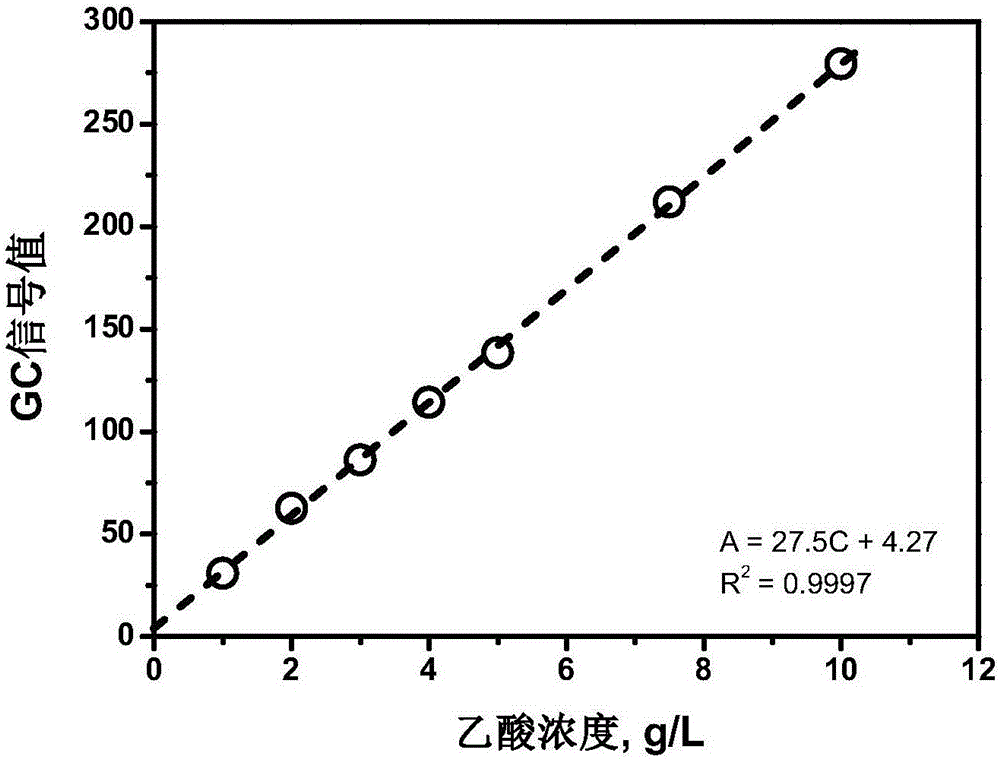

A method for measuring acetic acid content in biomass pretreatment liquid

A technology for the content of pretreatment liquid and acetic acid, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of gas chromatography column and chromatography separation hazards, reduce detection speed, block liquid chromatography column and other problems, and achieve the elimination of matrix effect, simple sample preparation, high detection precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Accurately measure 1mL of bamboo ethanol pretreatment solution with a pipette gun and place it in a dry headspace bottle, add 50mL sulfuric acid solution (0.2mol / L), shake vigorously until mixed evenly to obtain the test solution, the test solution The concentration of hydrogen ions is 10 -2 mol / L, and placed in an ultrasonic oscillator for 5 minutes to remove air bubbles in the solution to be tested.

[0054] (2) Filter the solution to be tested in (1) with a 0.45mm water filter head, use a micro syringe to accurately measure 5mL of the filtered solution to be tested and add it to a dry headspace bottle (20mL), and use a The aluminum cap of the tetrafluoroethylene / butyl rubber gasket sealed the headspace bottle to obtain the headspace bottle to be tested.

[0055] (3) Place the headspace vial to be tested in (2) in an automatic headspace sampler for equilibration. Measure and record the acetic acid gas chromatography signal value A 0 =151.7. The conditions of t...

Embodiment 2

[0060] (1) Accurately measure 1 mL of eucalyptus dilute acid pretreatment solution with a pipette gun, place it in a dry headspace bottle, add 100 mL of oxalic acid solution (0.1 mol / L), shake vigorously until mixed uniformly to obtain the solution to be tested, and wait for The concentration of hydrogen ions in the solution is 10 -3 mol / L, and placed in an ultrasonic oscillator for 1 minute to remove air bubbles in the solution to be tested.

[0061] (2) Filter the solution to be tested in (1) with a 0.45mm water filter head, use a microsyringe to accurately measure 11mL of the filtered solution to be tested and add it to a dry headspace bottle (20mL), and use a The aluminum cap of the tetrafluoroethylene / butyl rubber gasket sealed the headspace bottle to obtain the headspace bottle to be tested.

[0062] (3) Place the headspace vial to be tested in (2) in an automatic headspace sampler for equilibration. Measure and record the acetic acid gas chromatography signal value A ...

Embodiment 3

[0067] (1) Use a pipette gun to accurately measure 1mL of the southern pine green liquid pretreatment solution and place it in a dry headspace bottle, add 300mL of phosphoric acid solution (2mol / L), shake vigorously until it is evenly mixed to obtain the solution to be tested. The hydrogen ion concentration of the solution was 0.1 mol / L, and placed in an ultrasonic oscillator for 3 minutes to remove air bubbles in the solution to be tested.

[0068] (2) Filter the solution to be tested in (1) with a 0.45mm water phase filter head, use a micro syringe to accurately measure 8mL of the filtered solution to be tested and add it to a dry headspace bottle (20mL), and use a poly The aluminum cap of the tetrafluoroethylene / butyl rubber gasket sealed the headspace bottle to obtain the headspace bottle to be tested.

[0069] (3) Place the headspace vial to be tested in (2) in an automatic headspace sampler for equilibration. Measure and record the acetic acid gas chromatography signal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com