Electric smelting forming method of CAP1400 main steam pipe penetration piece

A technology of main steam pipe and penetrating parts, which is applied in the field of electrofusion forming of CAP1400 main steam pipe penetrating parts, which can solve the problems of low utilization rate of forgings and large amount of machining, and achieve the effects of improving efficiency, saving costs and shortening product cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

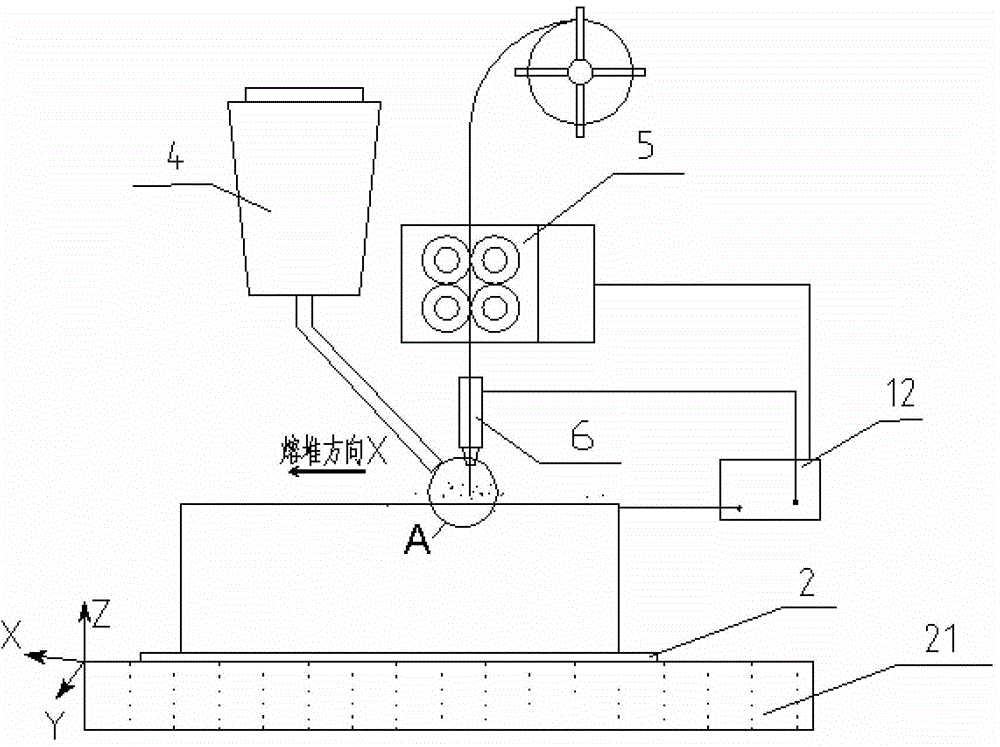

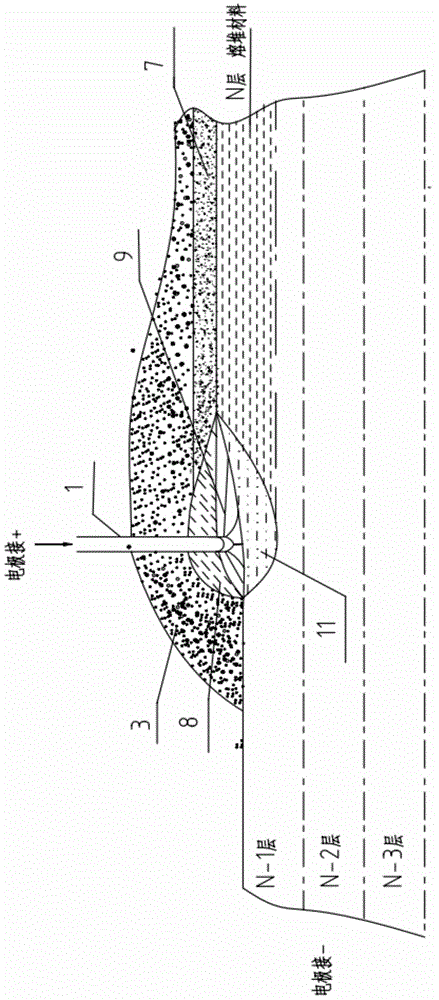

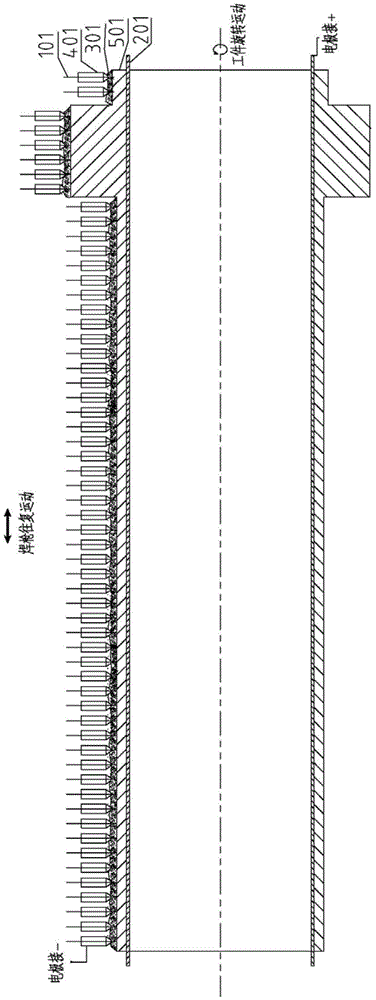

[0017] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. Figure 1A It is a schematic diagram for illustrating the principle of the electrofusion method in a specific embodiment; Figure 1B for Figure 1A Partial enlarged view near the location shown in A. Since it is a schematic diagram, the components in the diagram are schematic, and their actual shapes and dimensions are not limited by the diagram.

[0018] In this forming method, the raw wire material 1 is melted and deposited layer by layer (shown in FIG. 1 as the state when the Nth layer is deposited) on the base material 2, thereby finally forming a desired metal member.

[0019] The specific implementation process is:

[0020] A. The wire feeding mechanism 5 sends the raw material wire 1 to the surface of the base material 2 placed on the workbench 21 , which is covered with the granular auxiliary materials conveyed by the powder feeding mechanism 4 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com