Preparation method of metalloporphyrin oxygen sensing film

A technology of porphyrin oxygen sensing film and metal, which is applied in the direction of material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of long response time, low sensitivity, easy photodegradation of phosphorescent reagents, linear fitting strength, etc., and achieve a wide measurement range , high oxygen response performance, good light stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of a kind of metalloporphyrin oxygen sensing membrane of present embodiment is to carry out according to the following steps:

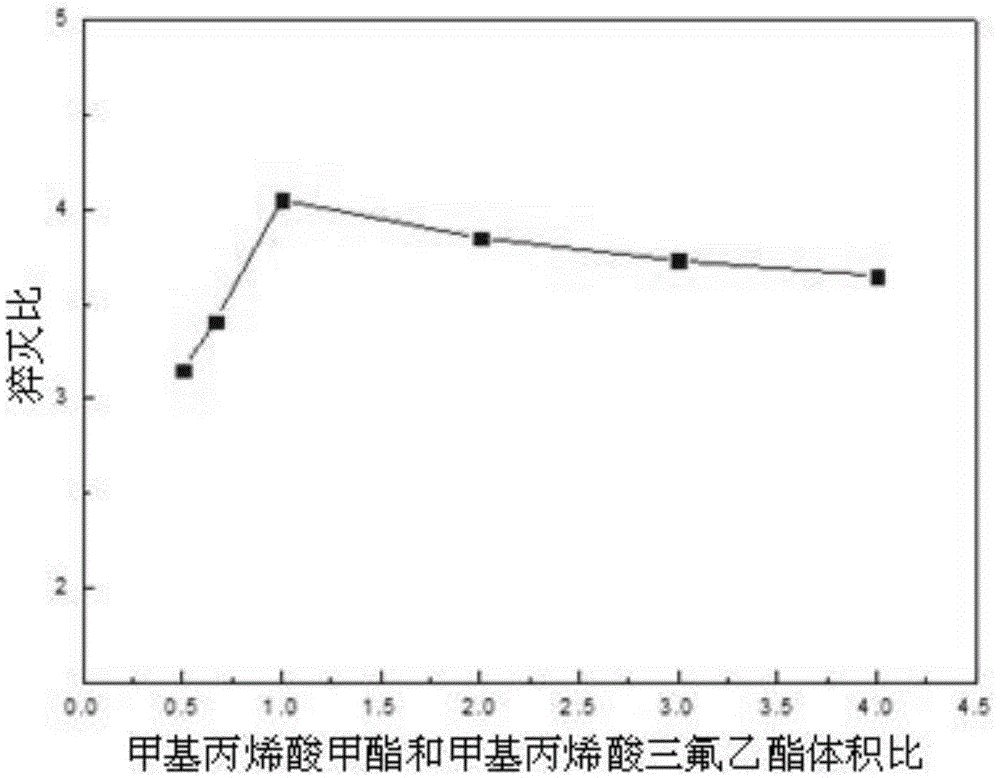

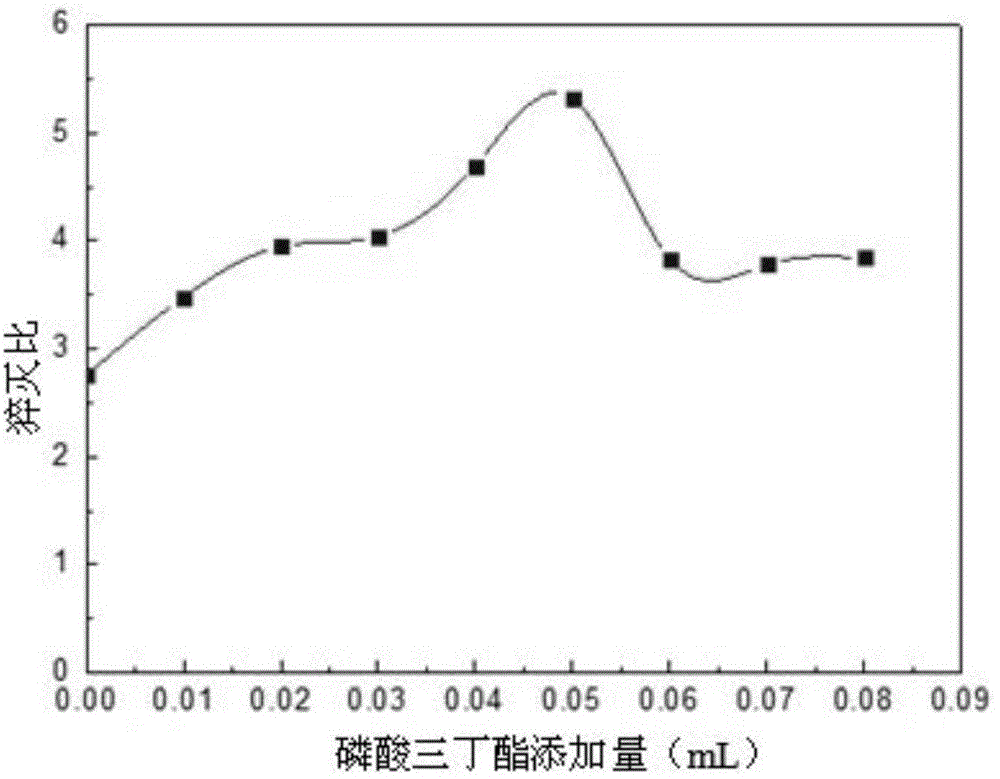

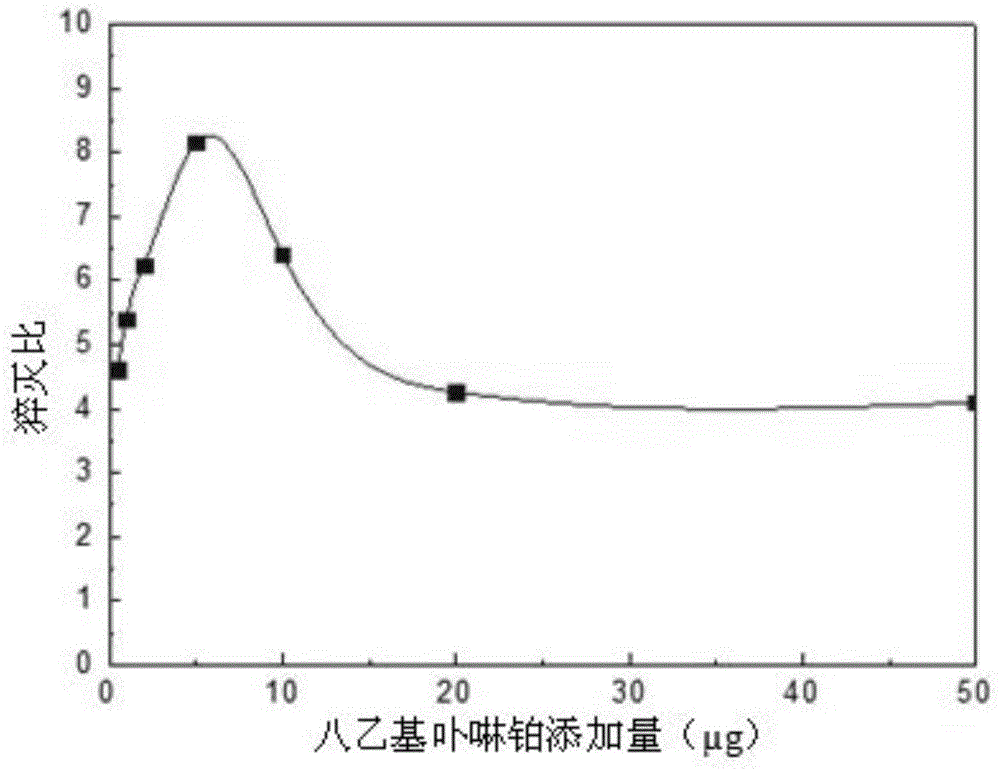

[0018] 1. 1. Mix methyl methacrylate and trifluoroethyl methacrylate to obtain a mixed solution; 2. Dissolve azobisisobutyronitrile with toluene to obtain an initiating solution; 3. Use a vortex shaker to mix solution and the triggering solution were mixed uniformly, heated in a water bath for 8h to 12h, cooled at room temperature, and washed with ethanol for 3 to 5 times to obtain a colorless and transparent copolymer; the methyl methacrylate and trifluoromethacrylate described in step 1 The volume ratio of ethyl ester is (0.5~4.5):1; The quality of azobisisobutyronitrile described in step one and the volume ratio of toluene are 1g:(50~200) mL; Mixed solution described in step one and The volume ratio of the triggering solution is (5-20):1;

[0019] 2. Put the colorless and transparent copolymer...

specific Embodiment approach 2

[0023] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: heating in a water bath for 10 hours in step 1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the volume ratio of methyl methacrylate and trifluoroethyl methacrylate described in step one is 1:1. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com