A kind of preparation method of metalloporphyrin oxygen sensing film

A technology of porphyrin oxygen sensing film and metal, which is applied in the direction of material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of low sensitivity, long response time, easy photodegradation of phosphorescent reagents, linear fitting strength, etc., and achieve oxygen response performance High, wide measurement range, good photostability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of a kind of metalloporphyrin oxygen sensing membrane of present embodiment is to carry out according to the following steps:

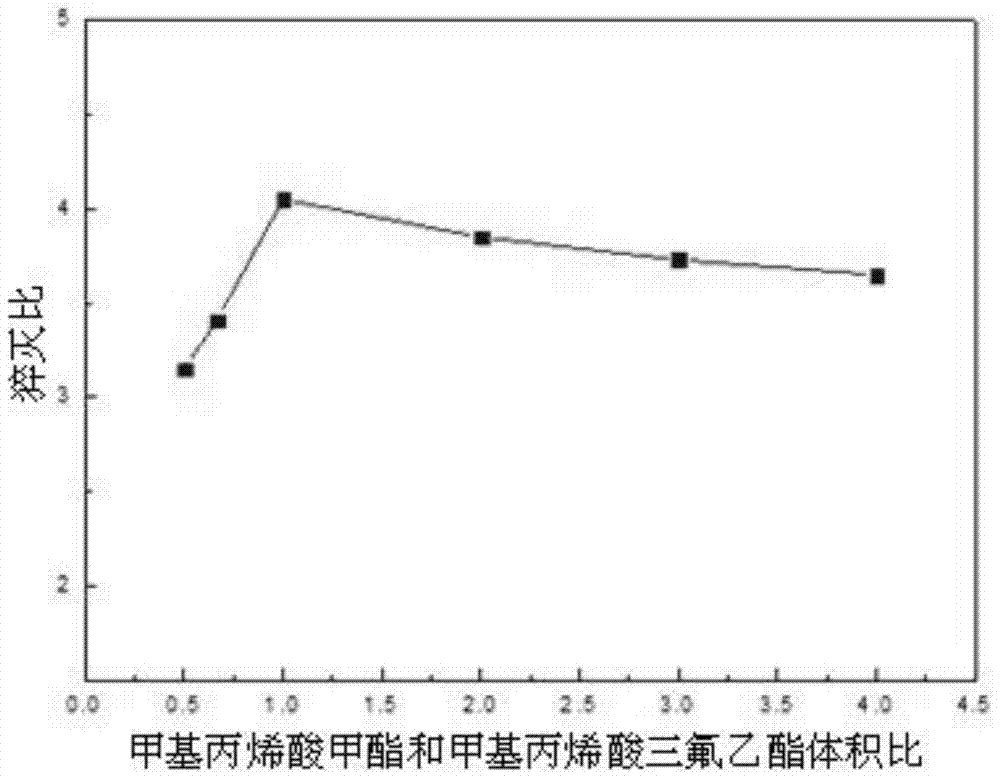

[0018] 1. 1. Mix methyl methacrylate and trifluoroethyl methacrylate to obtain a mixed solution; 2. Dissolve azobisisobutyronitrile with toluene to obtain an initiating solution; 3. Use a vortex shaker to mix solution and the triggering solution were mixed uniformly, heated in a water bath for 8h to 12h, cooled at room temperature, and washed with ethanol for 3 to 5 times to obtain a colorless and transparent copolymer; the methyl methacrylate and trifluoromethacrylate described in step 1 The volume ratio of ethyl ester is (0.5~4.5):1; The quality of azobisisobutyronitrile described in step one and the volume ratio of toluene are 1g:(50~200) mL; Mixed solution described in step one and The volume ratio of the triggering solution is (5-20):1;

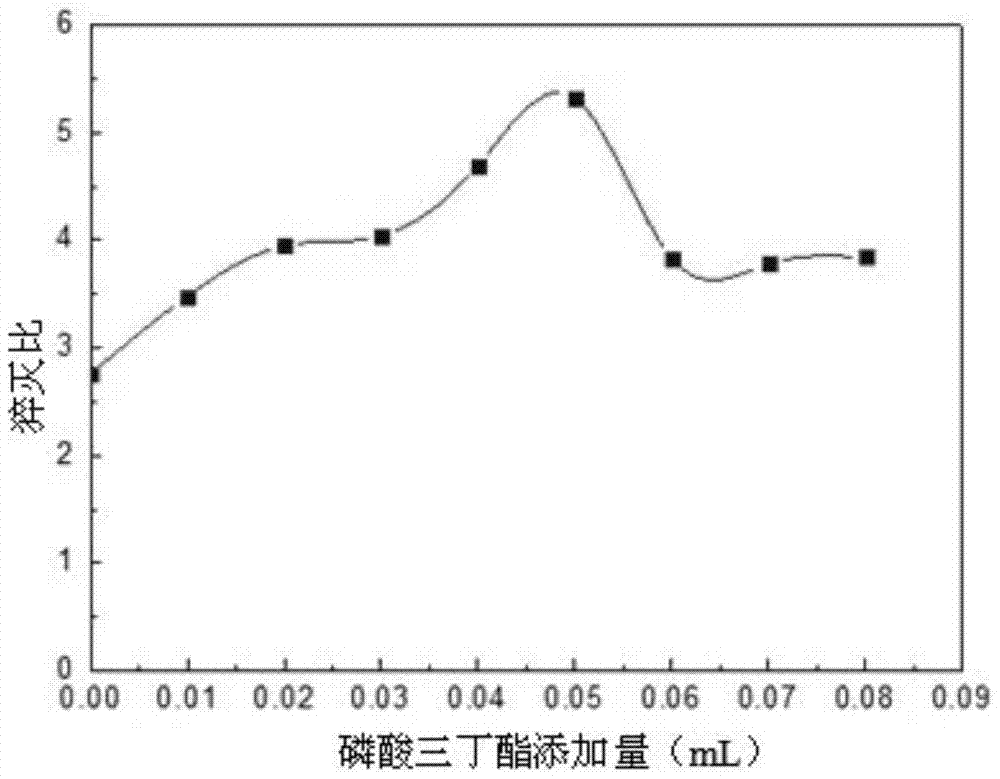

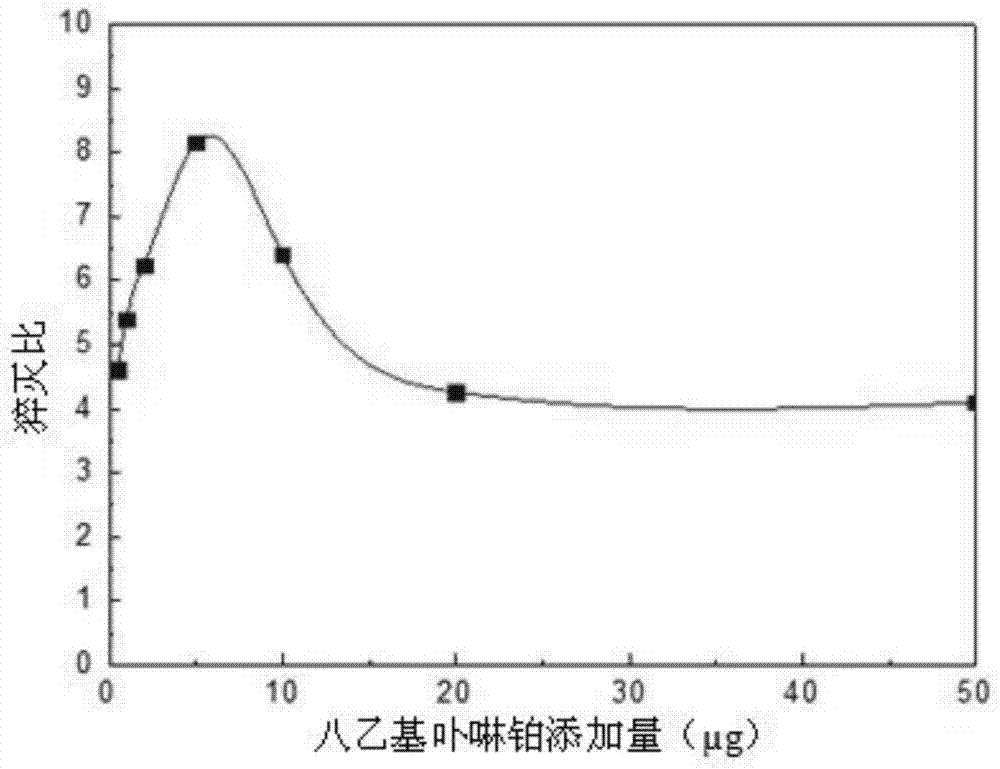

[0019] 2. Put the colorless and transparent copolymer...

specific Embodiment approach 2

[0023] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: heating in a water bath for 10 hours in step 1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the volume ratio of methyl methacrylate and trifluoroethyl methacrylate described in step one is 1:1. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com