Sodium polyacrylate-grafted and sodium alginate-embedded probiotic microcapsule and preparation method thereof

A technology of sodium polyacrylate and sodium alginate, used in microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of large gel pores and inability to effectively block the infiltration of gastric acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

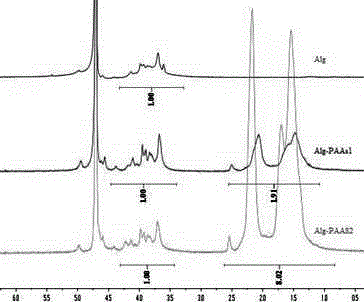

[0034] Example 1: Synthesis and characterization of sodium polyacrylate grafted with sodium alginate 1# (Alg-PAAs1)

[0035] Dissolve 1 g of sodium alginate (Alg) (weight-average molecular weight: 2×106) in 20 mL of water, the concentration of Alg is about 50 mg / mL, stir well until it is completely dissolved, heat up to 58 °C under nitrogen atmosphere, and continue Stir for 30 min, add 0.09 g of ammonium persulfate, and initiate at this temperature for 15 min; neutralize the acrylic acid monomer with sodium hydroxide solution under ice-water bath conditions, and slowly drop 0.72 g of sodium acrylate monomer into the Alg solution , raised the temperature to 70°C for 2 h, adjusted the pH of the solution to 6.5, dialyzed the solution against water for 2 d, and freeze-dried to obtain sodium polyacrylate grafted sodium alginate 1# (Alg-PAAs1). figure 1As shown, the detection results show that the z / (x+y) in the Alg-PAAs1 structure is about 2:1, which is basically close to the feedi...

Embodiment 2

[0036] Example 2: Synthesis and characterization of sodium polyacrylate grafted with sodium alginate 2# (Alg-PAAs2)

[0037] Dissolve 1 g of sodium alginate (Alg) (weight-average molecular weight: 3×106) in 100 mL of water, the concentration of Alg is about 10 mg / mL, stir well until it is completely dissolved, heat up to 62 °C under nitrogen atmosphere, and continue Stir for 60 min, add 0.20 g of ammonium persulfate, and initiate at this temperature for 15 min; neutralize the acrylic acid monomer with sodium hydroxide solution under ice-water bath conditions, and slowly drop 2.88 g of sodium acrylate monomer into the Alg solution , raised the temperature to 80°C for 3 h, adjusted the pH to 7.4, dialyzed the solution against water for 3 d, and freeze-dried to obtain sodium polyacrylate grafted sodium alginate 2# (Alg-PAAs2). z / (x+y) is approximately 8:1. Calculation based on the feed ratio: x / (x+y)=10:50 in the structural formula of Alg-PAAs1.

[0038] Material Viscosity ...

Embodiment 3

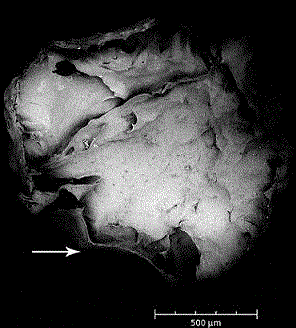

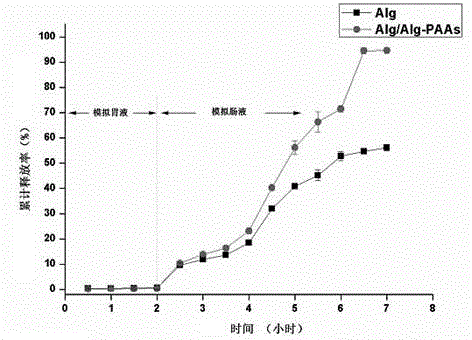

[0043] Example 3: Preparation and Characterization of Hollow Microcapsules

[0044] 1. Preparation of Alg / Alg-PAAs1 microcapsules

[0045] Mix 1 wt% Alg-PAAs1 and 3 wt% Alg solution at a mass ratio of 1:1, add dropwise to 0.3 mol / L calcium chloride solution, and transfer to 0.5 wt% pH after solidification at 4°C for 60 min =5.8 chitosan solution for 15 min, washed with sterile water to obtain the hollow microstructure with sodium alginate and sodium polyacrylate grafted with sodium alginate 1# (Alg / Alg-PAAs1) as the inner wall material capsule.

[0046] 2. The 2 wt% Alg solution was made into hollow microcapsules with sodium alginate (Alg) as the inner wall material by the same method.

[0047] Characterization of Alg / Alg-PAAs1 Hollow Microcapsules

[0048] 1) Particle size of microcapsules

[0049] Blot the residual water on the surface of Alg / Alg-PAAs1 or Alg hollow microcapsules on filter paper, and measure the particle diameters of 10 microspheres randomly with a verni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com