Series winding type brushless rotor doubly-fed generator analyzing method

A doubly-fed motor and analysis method technology, applied in the field of power equipment analysis based on multi-physical quantity coupling, can solve the complex electromagnetic characteristics of series-wound rotor brushless doubly-fed motors and hinder the series-wound rotor brushless doubly-fed motor Practical progress and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

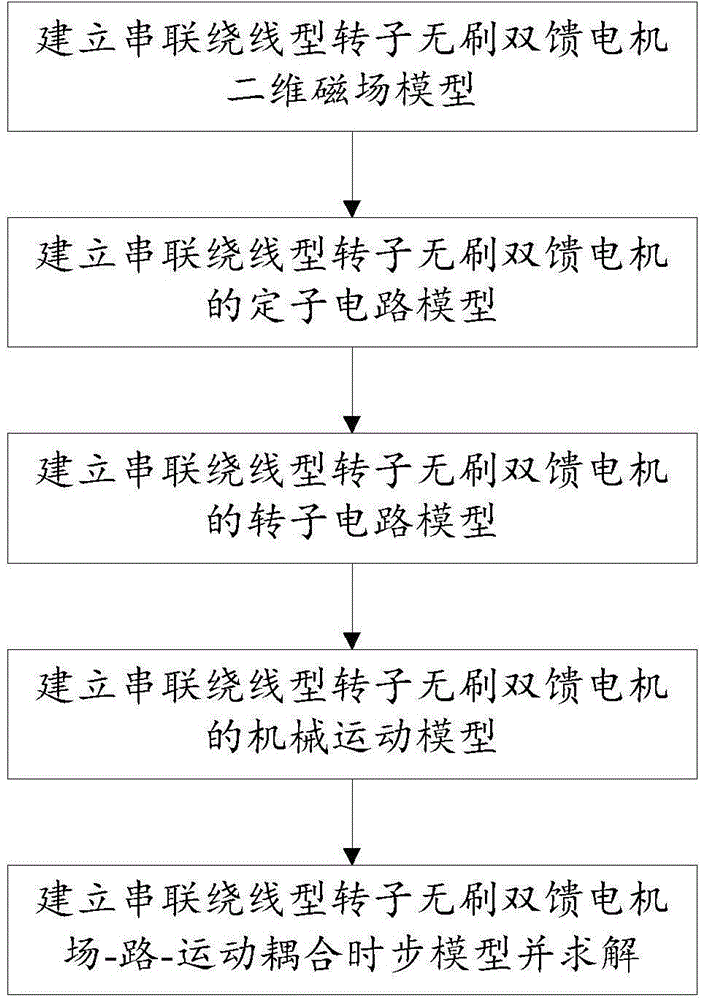

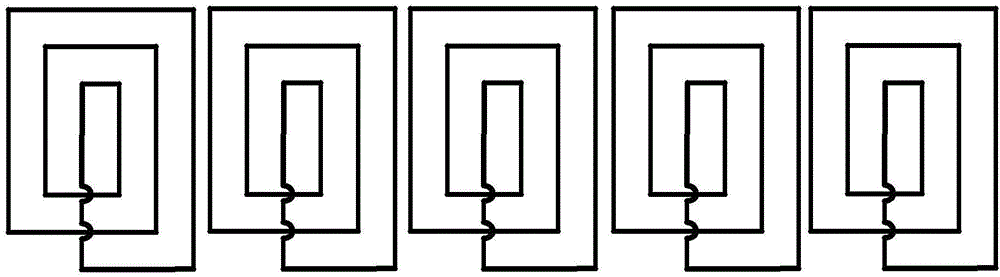

[0074] Take the power winding pole pair number p=4 and the control winding pole pair number q=1 as an example of a series wound rotor series wound rotor brushless double-fed motor. figure 1 The flow chart of the analysis method of the series wound rotor brushless double-fed motor, figure 2 It is a schematic diagram of the rotor connection with the number of poles p+q=5. Firstly, establish a two-dimensional model of a series-wound rotor brushless doubly-fed motor and divide it, then define the material properties of each structural part, set the excitation conditions and step length, and solve the magnetic field model, stator and rotor circuit model and rotor motion model simultaneously , Namely the field-path-motion coupled time-step finite element model. If the three-phase control winding is directly short-circuited, the motor realizes self-starting and asynchronous operation, and the voltage at the right end of the control winding circuit model excites U sc Is zero.

[0075]...

Embodiment 2

[0077] Taking the power winding pole pair number p=4 and the control winding pole pair number q=1 as an example, the difference from Embodiment 1 is that Embodiment 2 is used to analyze series winding The harmonic content of the air gap flux density at the moment of asynchronous and stable operation of the type rotor brushless doubly-fed motor, such as Figure 4 Shown. It can be seen that the magnetic field not only contains 4 pairs of pole harmonics corresponding to the excitation windings, but also contains 1 pair of poles harmonics corresponding to the control windings, indicating that the series-wound type rotor has well realized the function of "pole number converter". The analysis result shows that the analysis method of the series-wound rotor brushless doubly-fed motor provided by the present invention can be used to analyze the temporal and spatial harmonic distribution characteristics of the motor.

Embodiment 3

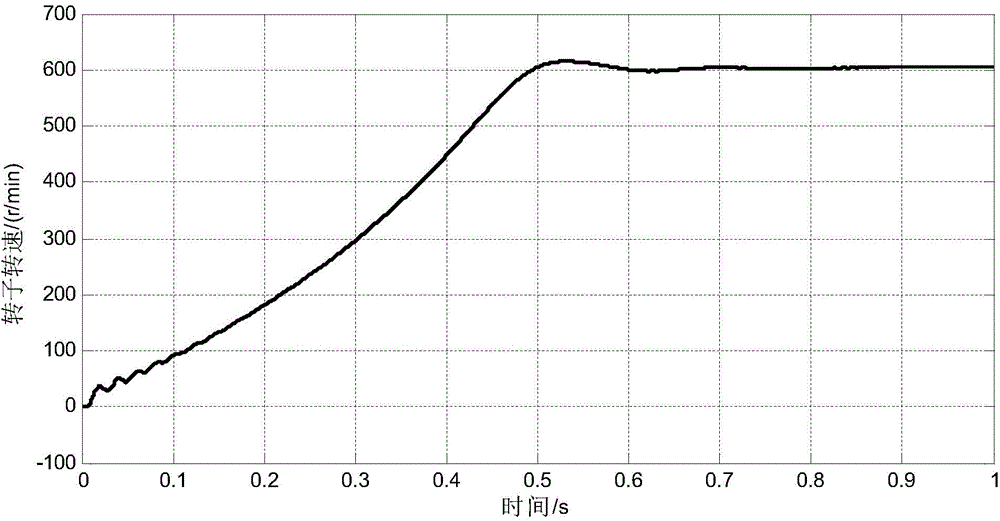

[0079] Taking the power winding pole pair number p=4 and the control winding pole pair number q=1 as an example, the difference from Embodiment 1 is that Embodiment 3 is used to analyze series winding Type rotor brushless doubly-fed motor super synchronous operation performance. When the control winding is powered by the variable frequency power supply, the motor realizes double-fed speed regulation operation, and when the phase sequence of the two sets of stator winding power supplies is the same, the motor runs in super-synchronous speed regulation. During speed regulation operation, the voltage at the right end of the control winding circuit model excites U sc The amplitude of is determined by the variable frequency power supply, with the variable frequency power supply voltage amplitude of 100V, frequency f c Taking 20Hz as an example, the super-synchronous operating speed curve of the series-wound rotor brushless doubly-fed motor based on the field-path-motion coupling tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com