Gas detection method and special sensor array thereof

A gas sensor and sensor array technology, applied in the field of spectral analysis, can solve the problems of unavoidable thermal background, interference, weak catalytic luminescence response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

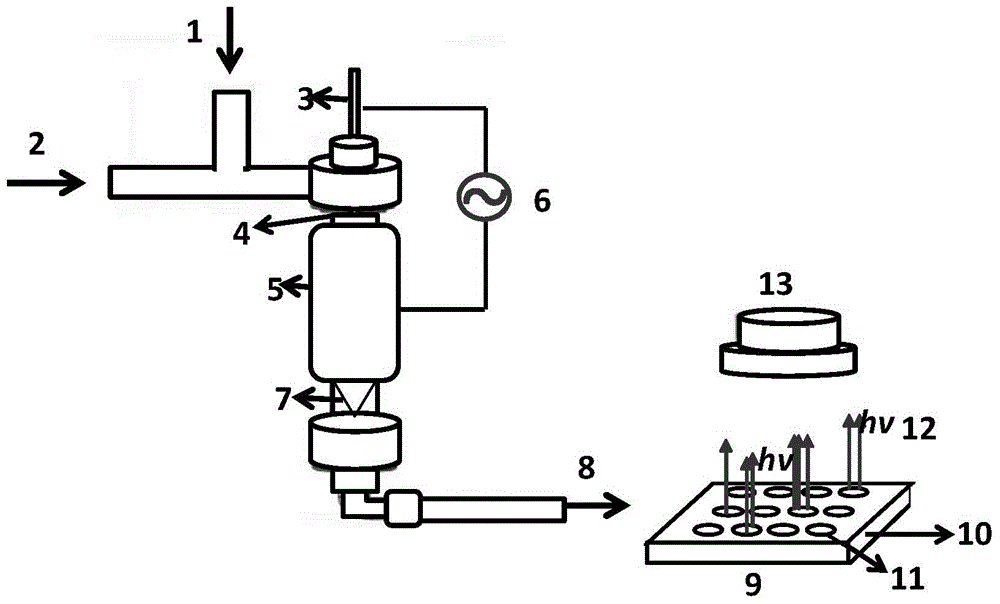

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1, the comparative test with or without low-temperature plasma assistance

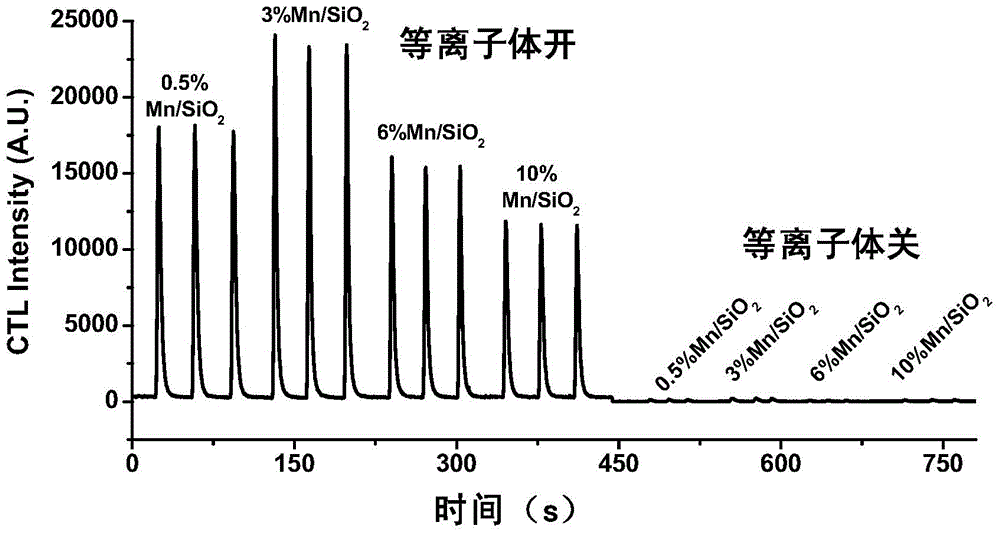

[0077] In order to determine the auxiliary performance of low-temperature plasma, the metal Mn-loaded SiO 2 Taking nanomaterials as an example, in response to CO, compare the chemiluminescence signals generated with and without plasma assistance. In the experiment, 1 mL of CO gas was injected, the air carrier gas flow rate was 100 mL / min, and the experimental temperature was 25 °C (catalytic temperature). In the experiment, nanomaterials with different metal doping ratios were selected as the response of the sensing unit, respectively 0.5% Mn / SiO 2 , 3%Mn / SiO 2 , 6%Mn / SiO 2 , 10% Mn / SiO 2 , the result is as figure 2 .

[0078] Depend on figure 2 It can be seen that when there is no plasma assistance, the four materials do not get obvious response signals, but when the high-voltage alternating current of the plasma is turned on, a high response signal is obtained in response t...

Embodiment 2

[0079] Embodiment 2, the impact of carrier gas and carrier gas velocity

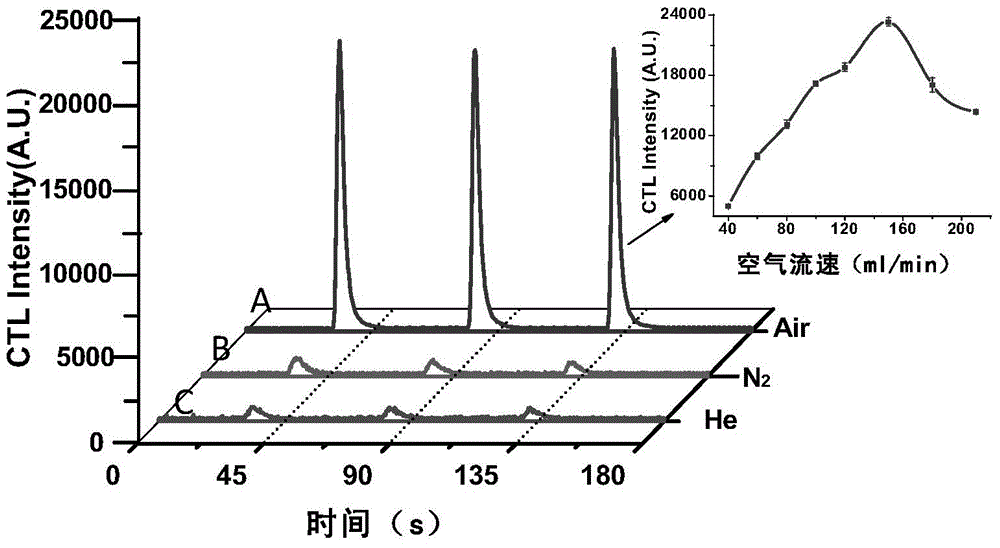

[0080] In the experiment, 1mL CO gas was injected, the air carrier gas flow rate was 100mL / min, the experimental temperature was 25°C (catalytic temperature), and the sensing element material was 3% Mn / SiO 2 .

[0081] Since air, nitrogen, helium, etc. can all be used as the generation gas of the low-temperature plasma. like image 3 , this embodiment compares the signal intensity of the response signal of CO obtained when helium, nitrogen, and air are respectively used as the generating gas of the low-temperature plasma. It can be seen that when air is used as the generating gas of the low-temperature plasma, a stronger Respond to the signal. Through the response signal repeated three times, it can be explained that the detection system using air as the carrier gas can obtain a response signal with good signal and good repeatability for the gas sample. and from attached image 3 It can be seen that...

Embodiment 3

[0082] Embodiment 3, the influence of nano catalytic material

[0083] In the experiment, 1mL of sample gas was injected, the air carrier gas flow rate was 100mL / min, and the experimental temperature was 25°C (catalytic temperature).

[0084] In this embodiment, 16 different nano catalytic materials are selected as sensing units to construct a sensor array to respond to different gaseous alkane samples. As shown in Table 1, the nano-catalytic materials of No. 0-15 are MgO, ZnO, TiO 2 , 10% Fe / ZnO, 10% Fe / SiO 2 , 10%Ag / ZnO, 10%Mn / ZnO, 5%Ag / TiO 2 , 10%Co / TiO 2 , 3.18%Ag / MgO, 10%Co / ZnO, 5%Fe / TiO 2 , 10% Au / TiO 2 , 10% Au / ZnO, 10% Ag / TiO 2and 5%Pt / TiO 2 ,As shown in Table 1. The selected gaseous hydrocarbon sample gases include CO, C 2 h 2 、C 3 h 8 、CH 4 and C 2 h 4 , the experimental results are as Figure 4 The comparison chart shown.

[0085] Table 1, No. 0-15 nano catalytic materials

[0086]

[0087] Depend on Figure 4 It can be seen that the response s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com