A structure and method for preventing corrosion damage of downhole aluminum alloy-carbon steel pipe column

A technology for corrosion damage of aluminum alloy tubes, applied in the direction of drill pipes, casings, drilling equipment, etc., can solve the problems that aluminum alloy anodes cannot be completely self-healed in time, the hardness of aluminum oxide film is high, and the joints are damaged and invalid. Well operation and production conditions, strong maintainability, and the effect of preventing contact damage and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

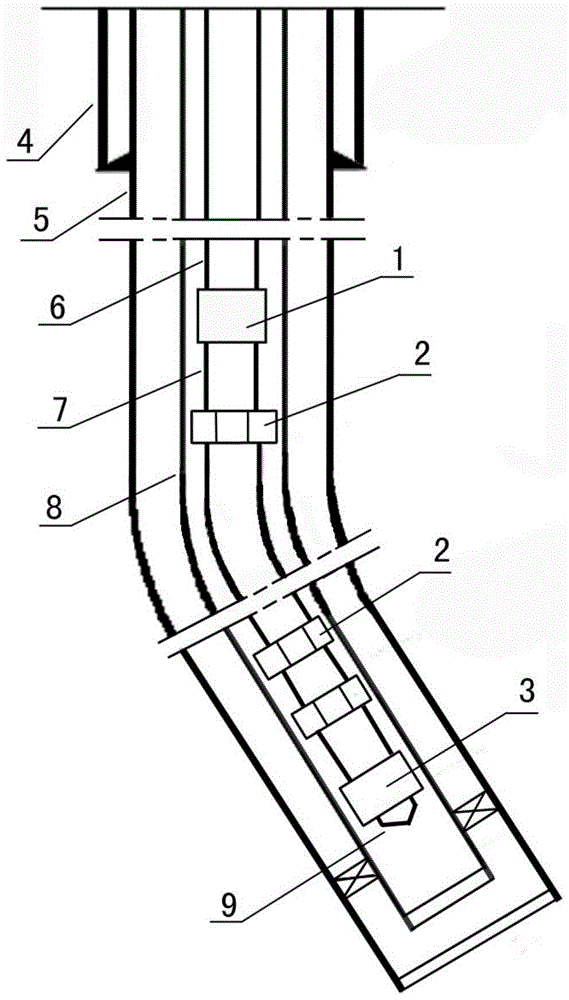

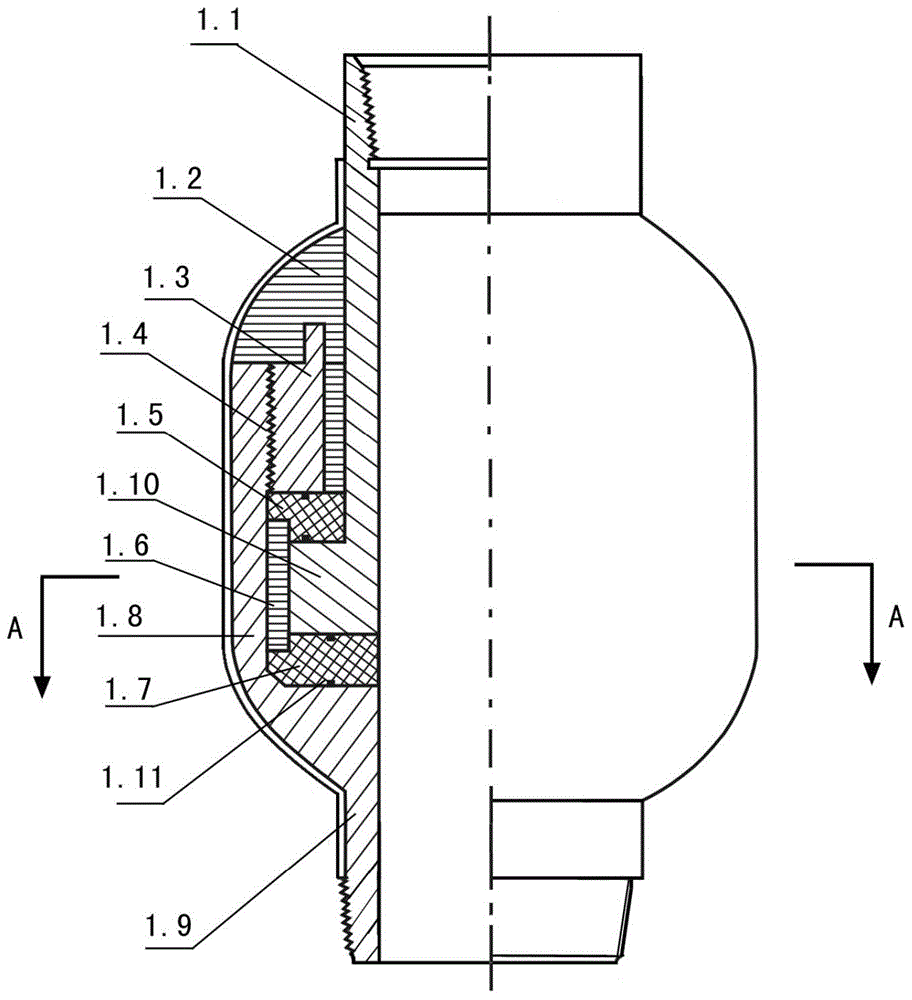

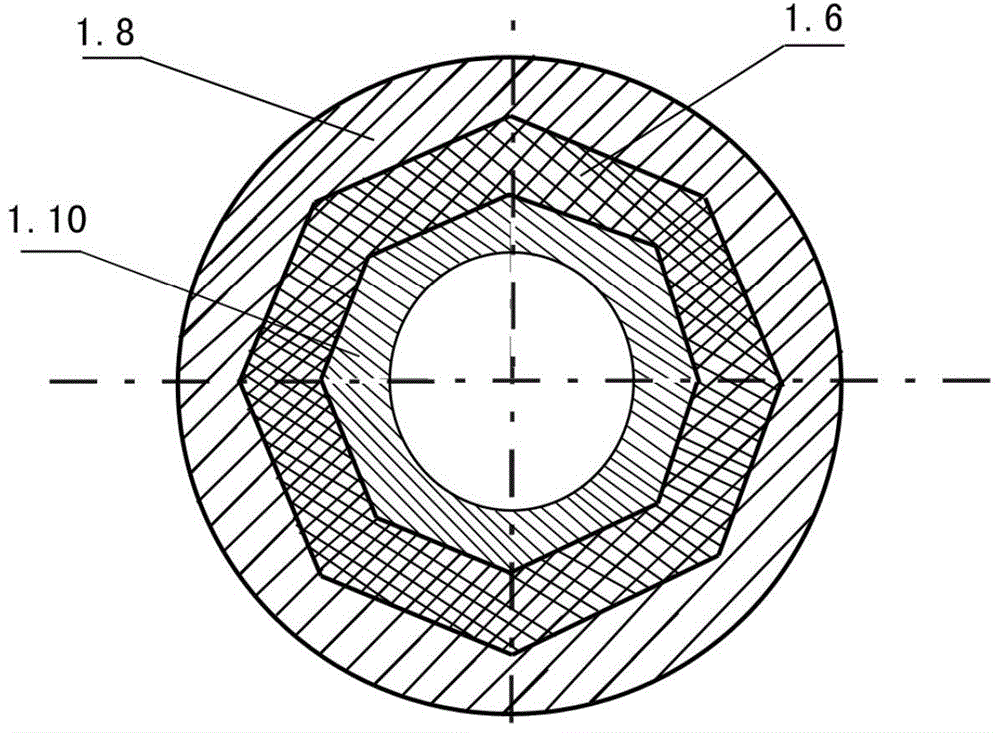

[0045] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 as shown,

[0046] A structure and method for preventing corrosion damage of downhole aluminum alloy-carbon steel pipe column, in particular a structure mode for preventing downhole aluminum alloy-carbon steel pipe column corrosion damage.

[0047] A structural model for preventing corrosion damage of an aluminum alloy-carbon steel pipe column in a well is mainly composed of three parts: one is to install an insulating conversion joint 1 at the connection between the upper part of the aluminum alloy pipe and the carbon steel pipe. The second is to install the centralizer 2 on the aluminum alloy pipe string. The spacing distribution of the centralizer 2 on the aluminum alloy pipe string is calculated by combining the three-dimensional wellbore trajectory in the gas well space, the axial force and the lateral force at the centralizer, and passing the test from bottom to top. Calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com