Method for preparing flax fiber by ultrasonic combination of mucor circinelloides DK1 strain and hydrogen peroxide

A joint preparation technology of Mucor volvulus, applied in the field of biological textiles, can solve the problems of not being able to meet the needs of high-grade and high-count fabrics, the quality of degumming affects the appearance of fabrics, and the long time of degumming process, so as to achieve favorable environmental protection and anti-pollution capabilities Strong, low-cost processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

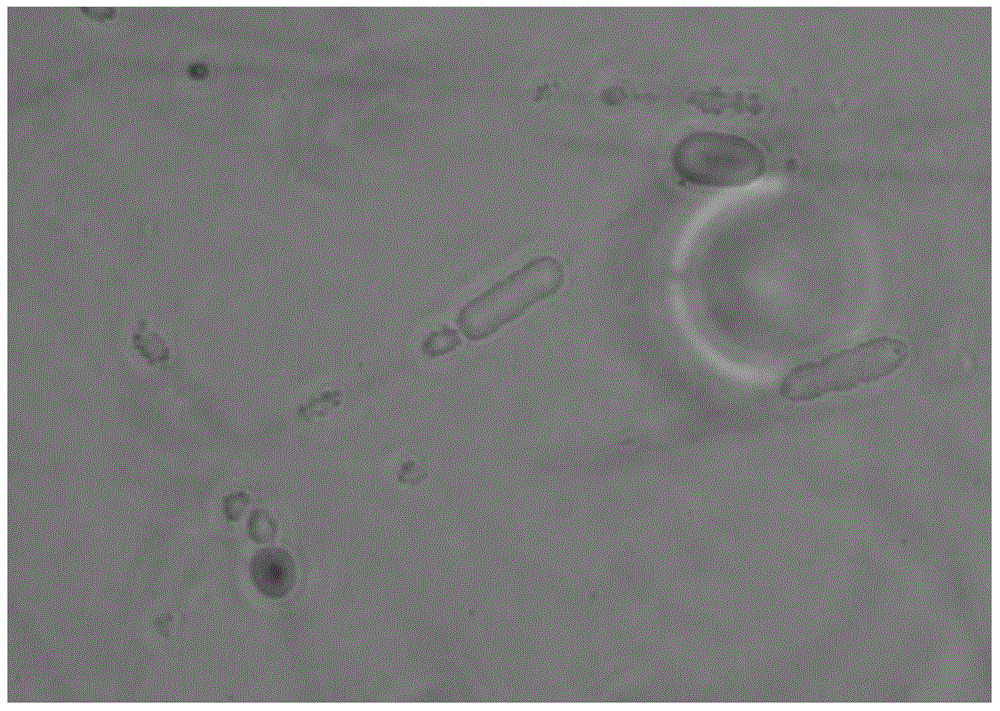

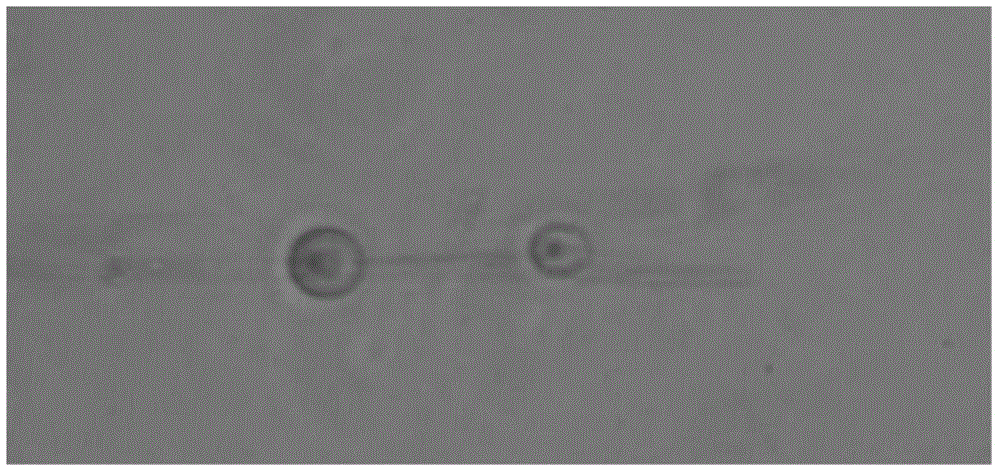

Image

Examples

Embodiment 1

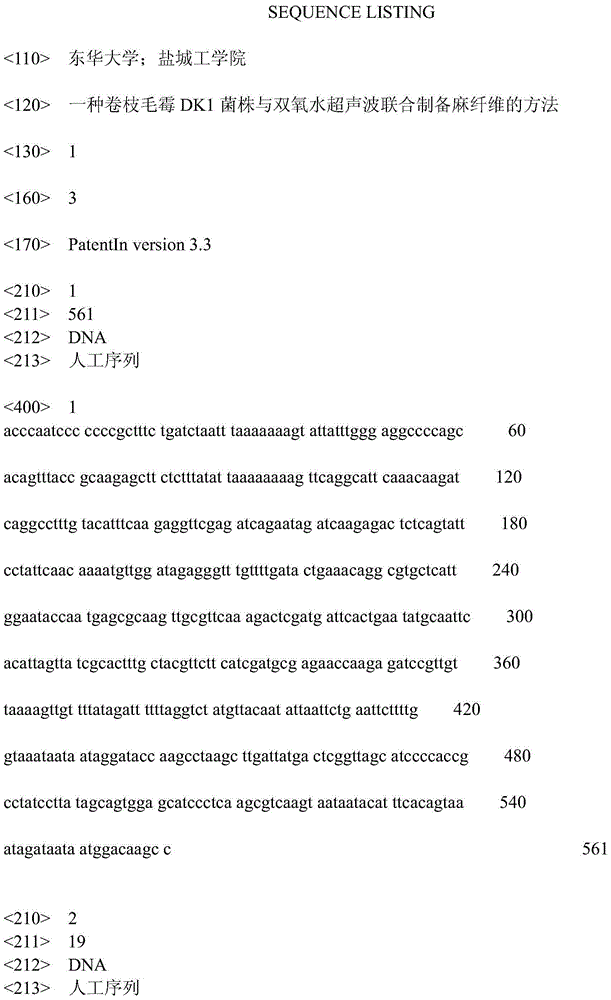

[0028] This embodiment records the method for preparing the degumming enzyme liquid by Mucor circiniferatum DK1:

[0029] (1) Preserve Mucor circinatus DK1 strain in PDA medium, culture at 200 rpm at 30°C for 24 hours, add freezing buffer; Into a 300mL Erlenmeyer flask, insert the obtained bacteria loop, and culture in a shaker at 150rpm at 28°C for 3 days, then culture the 50ml shaker flask, inoculate the culture medium into 5L of flax fermentation medium, and inoculate at a speed of 200r / min , Shake flask culture at a temperature of 30°C for 24 hours to obtain a fermentation broth. The fermentation broth was filtered through sterile gauze, the mycelium was washed with sterile water and dispersed in a Waring high-speed crushing cup for 10 seconds, and collected in sterile water. (with the same volume as the fermentation broth) to make a suspension of mycelium, and store it at 40°C for future use.

[0030] The formula of freezing buffer per 100ml is: potassium dihydrogen phos...

Embodiment 2

[0036] The process of preparing laccase from Mucor crimperida DK1 strain combined with hydrogen peroxide ultrasonic wave for flax raw stem degumming is as follows:

[0037] Put 5g of flax raw stems in a 250ml Erlenmeyer flask, fill the flask with a mixture of flax stems, crude enzyme solution and hydrogen peroxide at a ratio of 1:20, the liquid volume is 100ml, the pH value of the mixture is 6.0, flax The mass ratio of the original stem to the hydrogen peroxide is 1:5, and the mass ratio to the crude enzyme solution is 1:15. Degumming at 40°C and 200rpm shaker for 1 day, 2 days and 4 days respectively, the ultrasonic power is 80%, and 10% sodium hydroxide is added after the set time, the set temperature is 75°C, and the heating rate is 1°C / min , the time is 5 hours, the ultrasonic power is 20%, the degumming time is up, remove the degumming liquid, rinse several times with tap water, to remove the bacteria and non-cellulose substances on the original flax stem, and complete th...

Embodiment 3

[0040] The process of preparing laccase from Mucor circinarius DK1 strain combined with hydrogen peroxide ultrasonic wave for ramie yarn is as follows:

[0041] Put 5g of ramie sterilized yarn (ramie roving or ramie spun yarn) into a 250ml conical flask, and divide the mixture of ramie yarn, crude enzyme solution and hydrogen peroxide into the conical flask at a ratio of 1:20, and the liquid volume is 100ml , the pH value of the mixed solution is 7.0, the mass ratio of ramie yarn to hydrogen peroxide is 1:1, and the mass ratio to crude enzyme solution is 1:19. Degumming at 10°C, 10rpm shaker for 10min, ultrasonic power 10%, add 0.5% sodium hydroxide after the set time, set temperature 50°C, heating rate 10°C / min, time 10min, ultrasonic power When the degumming time is up, remove the degumming liquid, rinse several times with tap water, to remove bacteria and non-cellulose substances on the ramie yarn, and complete degumming.

[0042] The observation of ramie yarn degumming fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com