QDF (quiescent direct furnace) direct reduction technology

A process and direct technology, applied in the field of direct reduction process, can solve the problems of high thermal shock resistance, unstable working conditions, difficult feeding, etc., to achieve uniform reducing atmosphere, reduce energy consumption and cost, and extend large walls. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

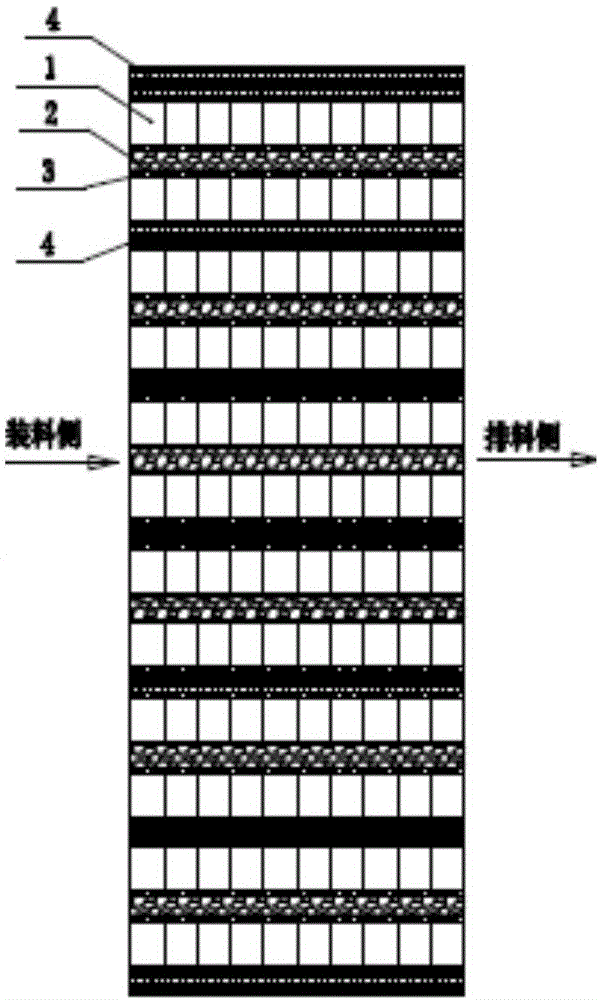

[0063] like Figure 2a As shown, a plurality of reduction chambers 2 and combustion chambers 1 are arranged at intervals, and a heat transfer partition wall 3 is arranged between adjacent reduction chambers 2 and combustion chambers 1. The temperature in each reduction chamber 2 is basically the same, which is suitable for treating a metal raw materials;

[0064] like Figure 2b As shown, a reduction chamber 2 is arranged in groups with two combustion chambers 1 located on both sides thereof, each group is separated by a large heat-insulating wall 4, and the temperature of each reduction chamber 2 can be independently controlled without being affected by each other. A variety of different metal-containing raw materials can be processed at the same time.

[0065] 5) The horizontal section of each reduction chamber 2 and combustion chamber 1 is trapezoidal or rectangular, and the vertical section is rectangular. The specific size of the reduction chamber 2 can be determined ac...

specific Embodiment

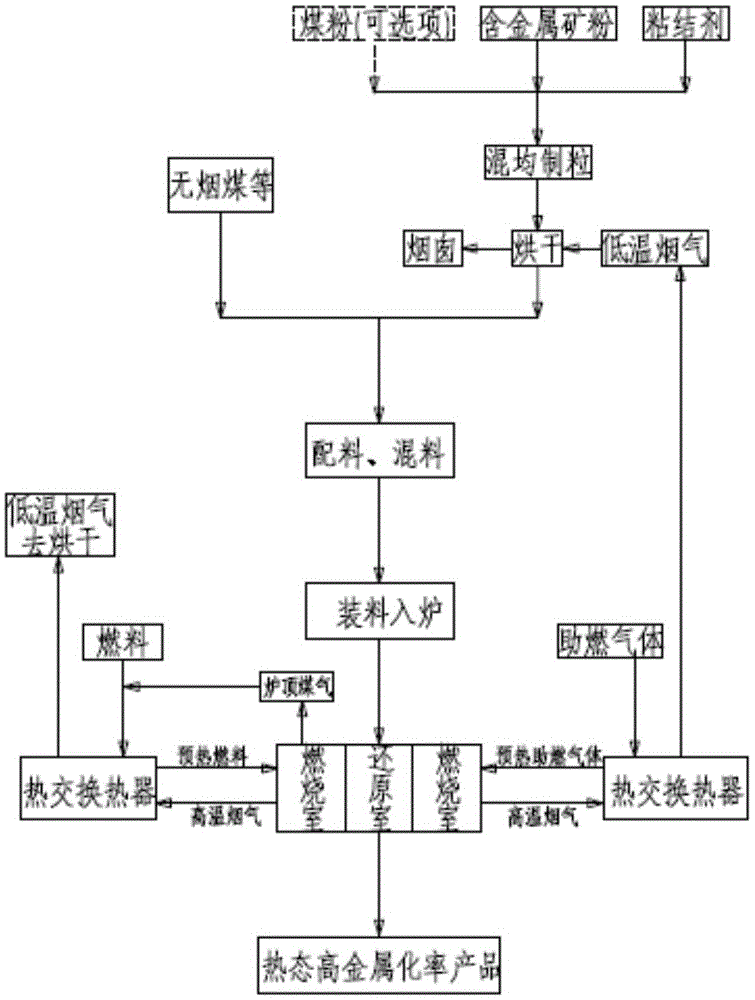

[0069] The specific embodiment of QDF direct reduction process of the present invention is as follows, comprises the following steps:

[0070] ST1: Fully mix the iron ore powder and binder with an iron content of more than 50% and then granulate it, with a particle size of about 30mm, dry it and transport it to the storage bin;

[0071] ST2: Mix the granular raw materials and anthracite reducing agent obtained above. The mass ratio of granular raw materials and reducing agent is about 1:0.3. , the bulk density is 2t / m 3 , the filling rate of the material in the reduction chamber is about 90%, and after the filling is completed, each feed port of the reduction chamber is automatically closed;

[0072] ST3: The reduction chamber is narrow and long, with a width of 300-550mm, a length of 5-18m, and a height of 3-8m;

[0073] ST4: The preheated gas supplied to the combustion chamber through the pipeline is 900°C and the preheated combustion air is 900°C;

[0074] ST5: Combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com