Method for continuously producing benzotriazole

A benzotriazole and production system technology, applied in the chemical industry, can solve problems such as survival difficulties, environmental pollution, and quality assurance, and achieve the effects of ensuring product quality, reducing environmental pollution, and realizing a virtuous circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

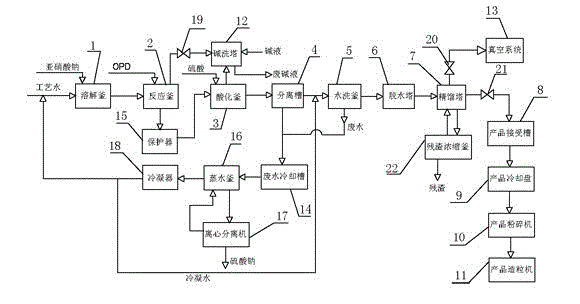

[0017] Example 1, see figure 1 , a method for continuous production of benzotriazole, specifically carried out in the following steps:

[0018] Step 1: Put the process water and solid sodium nitrite into the sodium nitrite dissolution kettle 1 according to the mass ratio of 1:0.4~0.7, start stirring, and at the same time, feed 2bar steam into the jacket of the dissolution kettle to raise the temperature, and finally maintain the temperature to 50 ℃~70℃ to completely dissolve the sodium nitrite, and form a sodium nitrite solution in the sodium nitrite dissolving kettle 1;

[0019] Step 2: According to the mass ratio of 0.4-0.6:1, the o-phenylenediamine (OPD) and the sodium nitrite solution formed in step 1 are respectively pumped into the reaction kettle 2 by using a high-pressure metering pump, and the heat transfer oil is turned on to raise the temperature and pressure to make the reaction kettle The pressure is finally kept at 4.5-5.5MPa, and the temperature is finally kept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com