Method and device for preparing bionic super-hydrophobic micro-nano surface through femtosecond laser

A femtosecond laser and super-hydrophobic micro-technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of poor film/coating bonding force, decreased hydrophobic function, poor environmental adaptability, etc., and achieve efficient processing , less consumption of raw materials, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

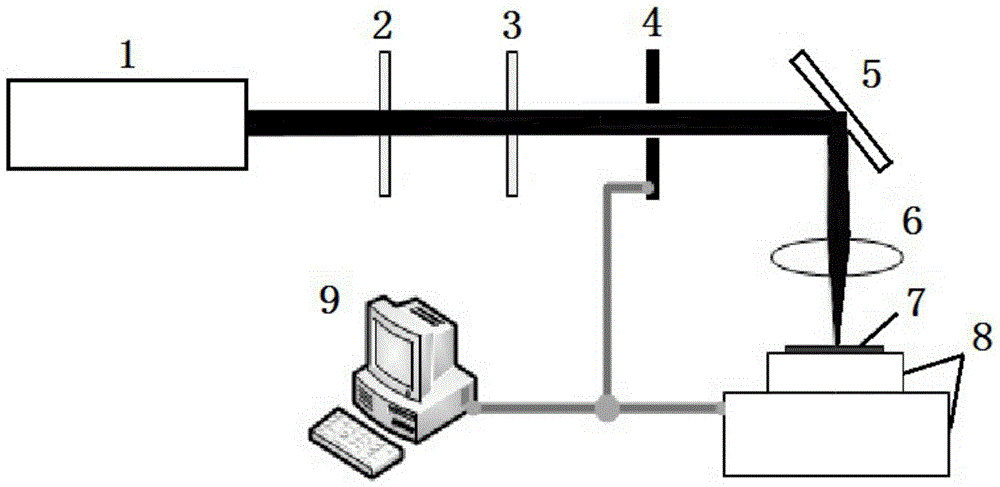

[0046] This embodiment provides a device for preparing bionic superhydrophobic micro-nano surface by femtosecond laser, such as figure 1 As shown, the device includes a femtosecond laser unit 1, a beam control unit, a motion platform unit 8 and an automatic control unit (industrial control computer) 9;

[0047] The femtosecond laser unit 1 comprises a femtosecond laser (the MAITI self-mode-locked titanium sapphire laser of American Spectrum Physics Corporation) and a regenerative amplifier (the Spitfire regenerative amplifier of the American Spectrum Physics Corporation), and the femtosecond laser is arranged at the rear of the regenerative amplifier; the present embodiment In , the femtosecond laser and the regenerative amplifier are industrially integrated to form a single unit;

[0048] The beam control unit comprises a half-wave plate 2, a polarization beam splitter 3, a shutter 4, a reflector 5 and an aspheric lens 6; the half-wave plate 2 is arranged in front of the rege...

Embodiment 2

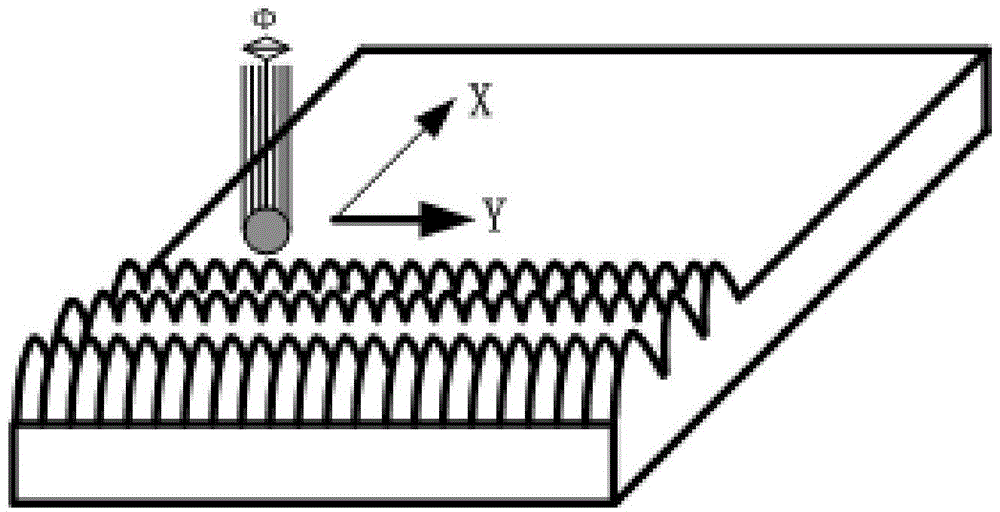

[0056] This example uses the femtosecond laser to prepare the bionic superhydrophobic micro-nano surface device and preparation method, the difference is that the single pulse energy of the femtosecond laser beam is 210 μJ, and at the same time, the step in the x direction is performed first during processing Feed amount, uniform speed movement processing in the y direction, and after the X direction processing is completed, then the step feed amount in the y direction, and uniform speed movement processing in the X direction.

[0057] The preparation method of this embodiment can obtain a cross-shaped superhydrophobic micro-nano surface, which has better superhydrophobic performance.

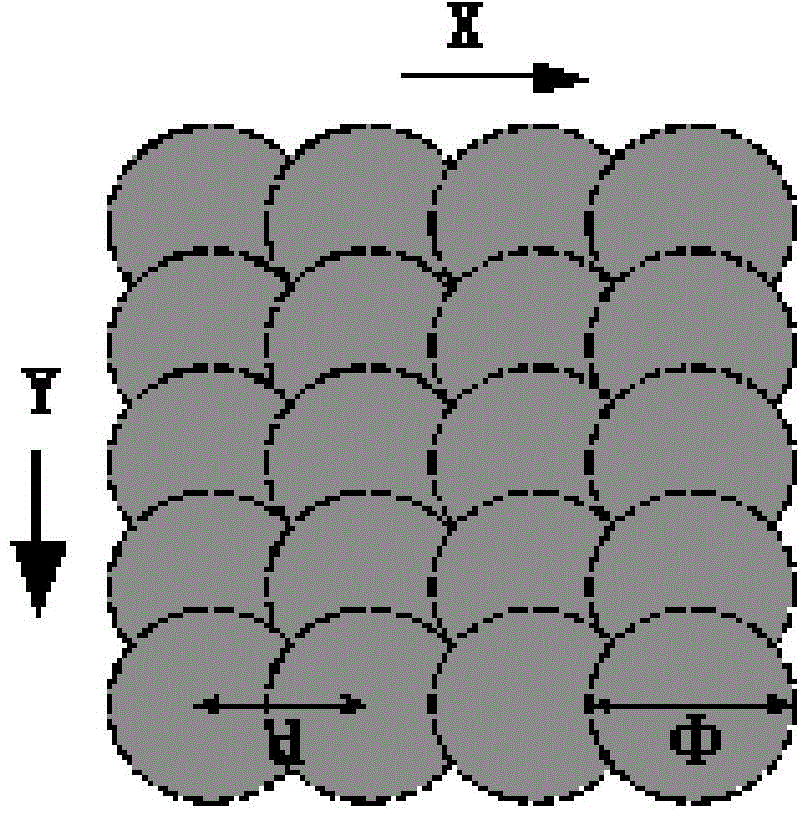

[0058] Scan the surface of the titanium alloy superhydrophobic micro-nano structure obtained in this embodiment using a scanning electron microscope, as Figure 5 As shown, the measured microstructure period is 100 μm and the depth is 50 μm. The static contact angle of the obtained titanium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com