Preparation method of TiO2/rGO composite

A technology of tetrabutyl titanate and absolute ethanol, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as not being used as electrocatalytic materials, and achieve easy reaction parameters The effect of control, short process and simple post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

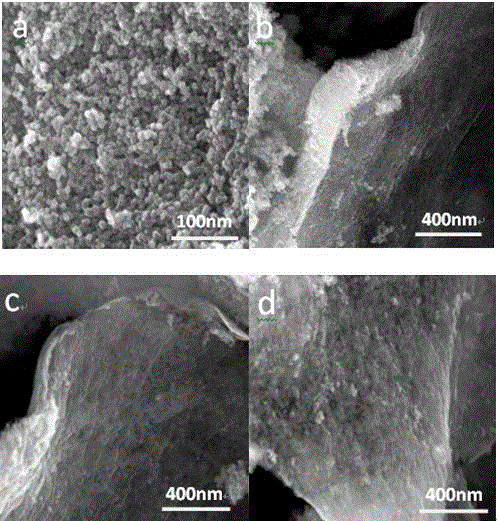

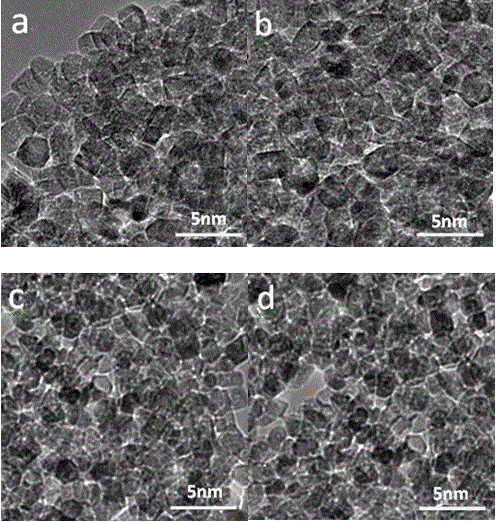

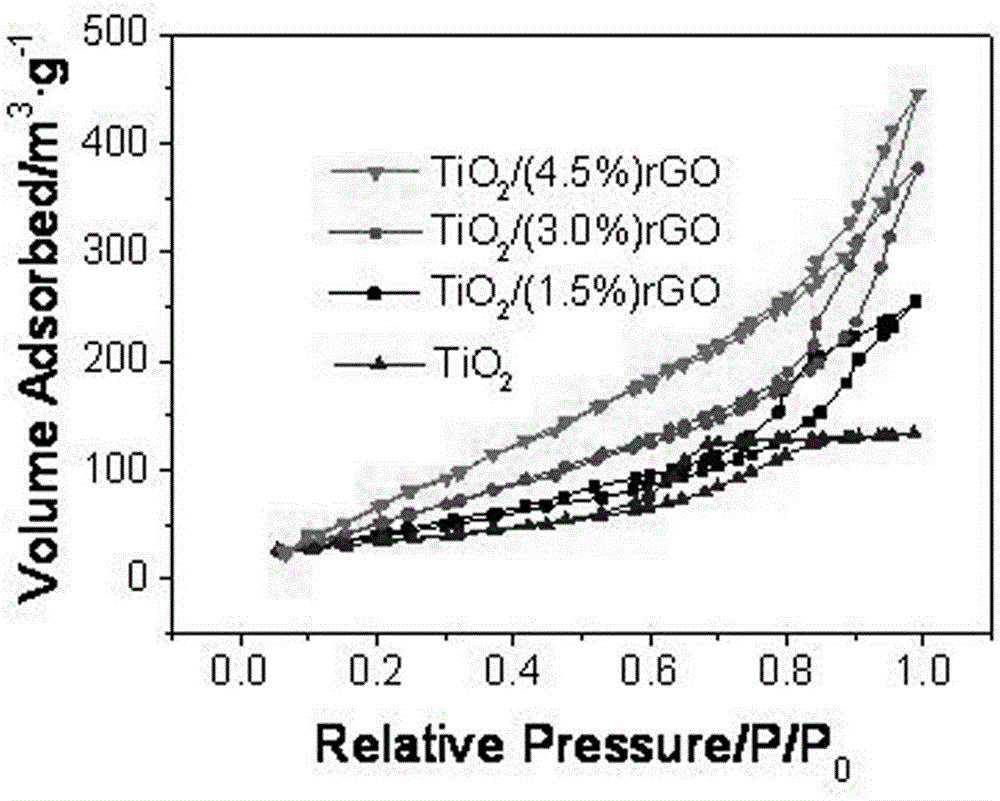

[0032] In a 50mL small beaker, while stirring with a magnetic stirrer, add 10.00mL of absolute ethanol, 3.00mL of ethylene glycol stock solution (pure ethylene glycol), slowly add 10.00mL of tetrabutyl titanate, and stir for 5 minutes to form a light Yellow transparent liquid, add 0.867g of ammonium fluoride, 1.406g of urea, 2mL of graphene oxide (1g / 100mL), stir until the solution is clear (about 5 min), and finally add 16.00mL of 6mol / L hydrochloric acid drop by drop, after fully stirring , transfer the reaction solution into a 100mL autoclave, heat to 200°C, take it out after 10 hours at constant temperature, wash the product three times with absolute ethanol, then wash three times with double distilled water, put it in a vacuum distillation device at 50°C Distilled under reduced pressure for 20 minutes to obtain a black powdery solid, which is TiO with high-efficiency electrocatalytic oxygen reduction performance. 2 / rGO composite material——TiO 2 / (1.5%) rGO.

[0033] ...

Embodiment 2

[0035] In a 50mL small beaker, while stirring with a magnetic stirrer, add 10.00mL of absolute ethanol and 3.00mL of ethylene glycol stock solution, slowly add 10.00mL of tetrabutyl titanate as the raw material, stir for 5min, a light yellow transparent liquid is formed, add fluoride Ammonia 0.867g, urea 1.406g, graphene oxide 4mL (1g / 100mL), stir until the solution is clear (about 5 min), and finally add 6mol / L hydrochloric acid 16.00mL dropwise, after fully stirring, transfer the reaction solution to 100 In a 1 mL high-pressure reactor, heat to 200°C, take it out after constant temperature for 10 hours, wash the product three times with absolute ethanol, and then wash three times with double distilled water, put it in a vacuum distillation device for 20 minutes under reduced pressure at 50°C, A black powdery solid is obtained, which is TiO with high-efficiency electrocatalytic oxygen reduction performance. 2 / rGO composite material——TiO 2 / (3.0%) rGO.

[0036] Characteri...

Embodiment 3

[0038] In a 50mL small beaker, while stirring with a magnetic stirrer, add 10.00mL of absolute ethanol and 3.00mL of ethylene glycol stock solution, slowly add 10.00mL of tetrabutyl titanate as the raw material, stir for 5min, a light yellow transparent liquid is formed, add fluoride Ammonia 0.867g, urea 1.406g, graphene oxide 6mL (1g / 100mL), fully stir the solution until it becomes clear (about 5 min), and finally add 6mol / L hydrochloric acid 16.00mL dropwise, after fully stirring, transfer the reaction solution into 100ml In a high-pressure reaction kettle, heat to 200°C, take it out after constant temperature for 10 hours, wash the product three times with absolute ethanol, then wash three times with double distilled water, put it in a vacuum distillation device for 20 minutes under reduced pressure at 50°C, and obtain Black powdery solid, which is TiO with high-efficiency electrocatalytic oxygen reduction performance 2 / rGO composite material——TiO 2 / (4.5%) rGO.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com