Method for recycling wasted SCR denitrification catalyst

A technology of SCR catalyst and denitrification catalyst, which is applied in the recycling field of waste SCR denitrification catalyst, can solve the problems of poor catalyst strength and wear resistance, short service life, failure of recovery, etc., and achieves simple operation, strong wear resistance, and reduced reuse cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

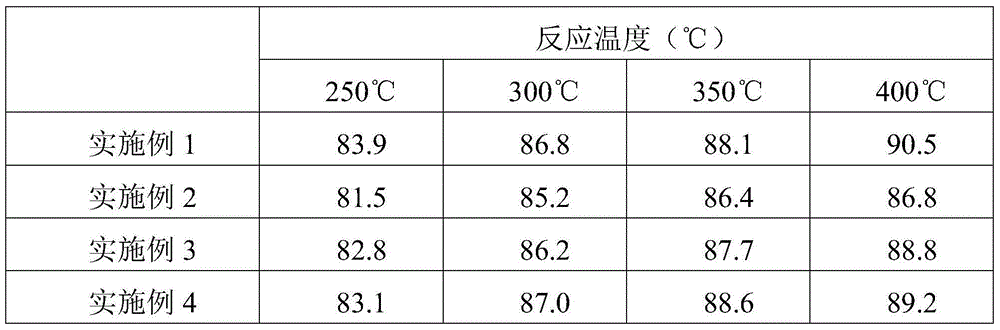

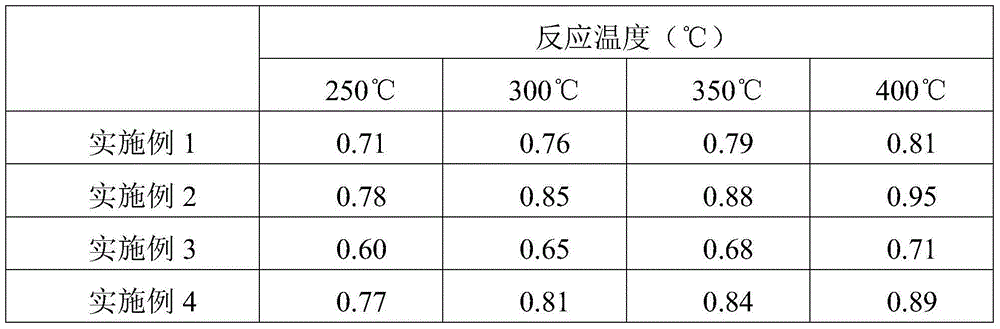

Examples

Embodiment 1

[0028] 1. Preparation of recycled waste denitrification catalyst

[0029] (1) the spent SCR catalyst is cleaned of surface dust with a vacuum device, and then the spent catalyst is cut into small pieces of 30 cm in length by a cutting machine;

[0030] (2) Put the cut catalyst into the cleaning solution, bubble and clean it for 20 minutes, take it out and rinse it with clean water;

[0031] (3) Put the cleaned catalyst into a drying oven and dry it at 120° C. for 3 hours;

[0032] (4) Using a pulverizer to pulverize the catalyst into 300-mesh particles to obtain the waste denitration catalyst recycle material.

[0033] 2. Preparation of denitrification catalyst

[0034] (1) ammonium molybdate is dissolved in the hot water of 60 ℃ and is mixed with the solution A that mass fraction is 20%;

[0035] (2) Ammonium metavanadate, oxalic acid and water are configured into solution B in a mass ratio of 1:2:5;

[0036] (3) 20 parts of solution A, 16 parts of solution B, 80 parts of...

Embodiment 2

[0039] 1. Preparation of recycled waste denitrification catalyst

[0040] (1) the spent SCR catalyst is cleaned of surface dust with a vacuum device, and then the spent catalyst is cut into small pieces with a length of 20 cm by a cutting machine;

[0041] (2) Put the cut catalyst into the cleaning solution, bubble and clean it for 10 minutes, take it out and rinse it with clean water;

[0042] (3) Put the cleaned catalyst into a drying oven, and dry it at 100° C. for 2 hours;

[0043] (4) Using a pulverizer to pulverize the catalyst into 100-mesh particles to obtain the waste denitration catalyst recycle material.

[0044] 2. Preparation of denitrification catalyst

[0045] (1) ammonium molybdate is dissolved in the hot water of 60 ℃ and is mixed with the solution A that mass fraction is 20%;

[0046] (2) Ammonium metavanadate, oxalic acid and water are configured into solution B in a mass ratio of 1:2:5;

[0047] (3) 10 parts of solution A, 8 parts of solution B, 70 part...

Embodiment 3

[0050] 1. Preparation of recycled waste denitrification catalyst

[0051] (1) the waste SCR catalyst is cleaned of surface dust with a vacuum device, and then the waste catalyst is cut into small pieces with a length of 50 cm by a cutting machine;

[0052] (2) Put the cut catalyst into the cleaning solution, bubble and clean it for 30 minutes, take it out and rinse it with clean water;

[0053] (3) Put the cleaned catalyst into a drying oven, and dry it at 150° C. for 4 hours;

[0054] (4) Using a pulverizer to pulverize the catalyst into 200-mesh particles to obtain the waste denitration catalyst recycle material.

[0055] 2. Preparation of denitrification catalyst

[0056] (1) ammonium molybdate is dissolved in the hot water of 60 ℃ and is mixed with the solution A that mass fraction is 20%;

[0057] (2) Ammonium metavanadate, oxalic acid and water are configured into solution B in a mass ratio of 1:2:5;

[0058] (3) 25 parts of solution A, 16 parts of solution B, 90 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com