Method for improving durability of lithium-ion power battery, and lithium-ion power battery

A power battery and lithium-ion technology, applied in the field of electrochemistry, can solve the problems affecting the durability of the battery, the end of the service life of the battery, and the inability to retain more electrolytes, etc., so that it is not easy to peel off or crack, the structure is complete, and the cycle performance is guaranteed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

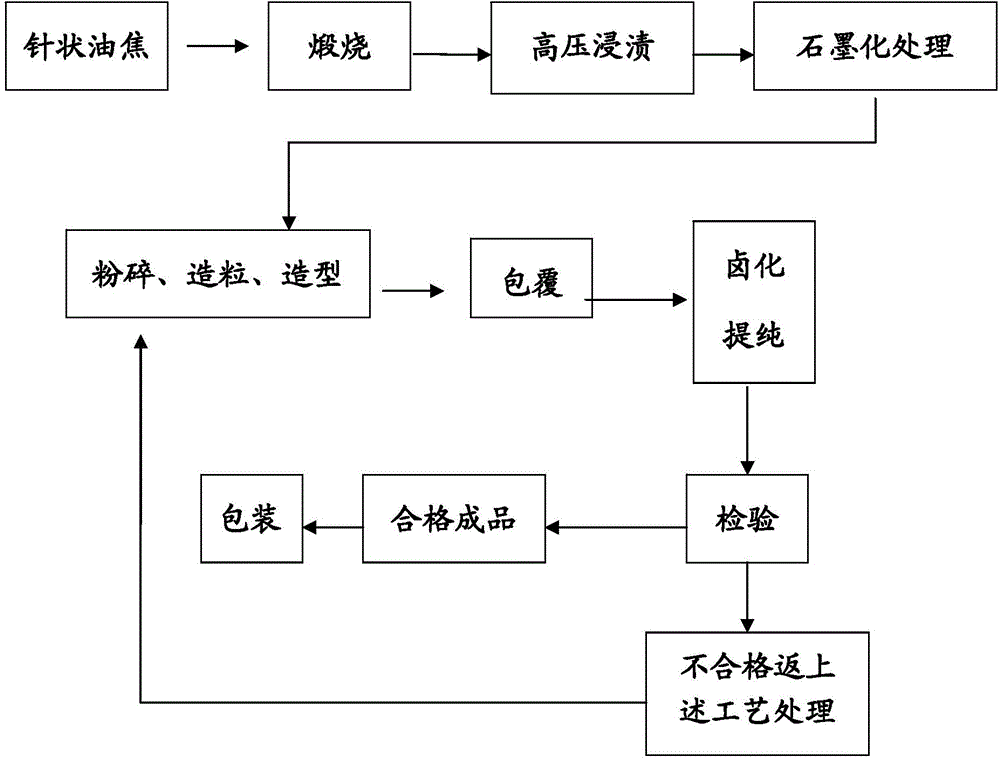

[0054] (1) Please refer to figure 1 Shown, the preparation method of negative electrode material provided by the invention comprises:

[0055] Calcining the oil-based needle coke raw material at 1300-1800°C until the pore size is 10-15%;

[0056] The calcined needle coke is mixed with liquid pitch at 100-300°C and 2-10 atmospheres for high-pressure impregnation until the pore size is 3-10%;

[0057] Graphitizing the impregnated needle coke at 3000-3800°C to obtain graphite with a pore size of 0.01-100 μm and a pore size of 50-70%;

[0058] Make the above graphite into D 10 ≥3μm, D 50 3~15μm, D 90 Graphite particles ≤20μm;

[0059] Coating the graphite particles with furan resin, bakelite resin or hard carbon;

[0060] The coated graphite particles are subjected to halogenation purification to obtain negative electrode materials.

[0061] Further, the ash content of the oil-based needle coke raw material is ≤0.16%, and the true specific gravity is 2.06-2.07g / cm 3 , the ...

Embodiment 1

[0130] To make a polymer lithium-ion power battery with a model number of 0495150 and a capacity of 7 Ah (Ah), the specific steps are as follows:

[0131] The oil-based needle coke raw material is calcined at 1300 °C, and the temperature of the raw material is about 300 °C, and the gap left after the volatile matter of the raw material is removed after calcination, such high-temperature needle coke is directly put into the vacuum autoclave for high-pressure Dipping, there is asphalt in the autoclave, after feeding such high-temperature needle coke, vacuumize, at a temperature of 100 to 300 degrees and a pressure of 2 to 10 atmospheres, the liquid asphalt penetrates into the pores of the needle coke, thereby To improve the tap density of the product. The porosity dropped from the original 10%-15% to about 3%. The resulting semi-finished product is packaged in a graphite clamp pot and subjected to graphitization treatment at 3000°C. Since the needle coke has been turned into g...

Embodiment 2

[0137] Different from Example 1, after obtaining the nano-barium sulfate slurry, mix the nano-barium sulfate slurry with 4-6 parts by weight of acrylate emulsion, foam the mixture, and adjust the foam density to 100-150 grams / L or so, use a foam spraying device to evenly spray the foam on the negative pole piece, dry the foam coating on the negative pole piece at a temperature of 60-70°C, roll it, and then bake it at 120-130°C In 3-5 minutes, a negative electrode coil with a nano-barium sulfate coating thickness of 1 to 50 microns is obtained, and then cut, soldered, taped and other sheet-making processes and processes are obtained to obtain a negative electrode sheet that can be used to make batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com