A cubic hole carbon coating separator for lithium metal battery and preparation method thereof

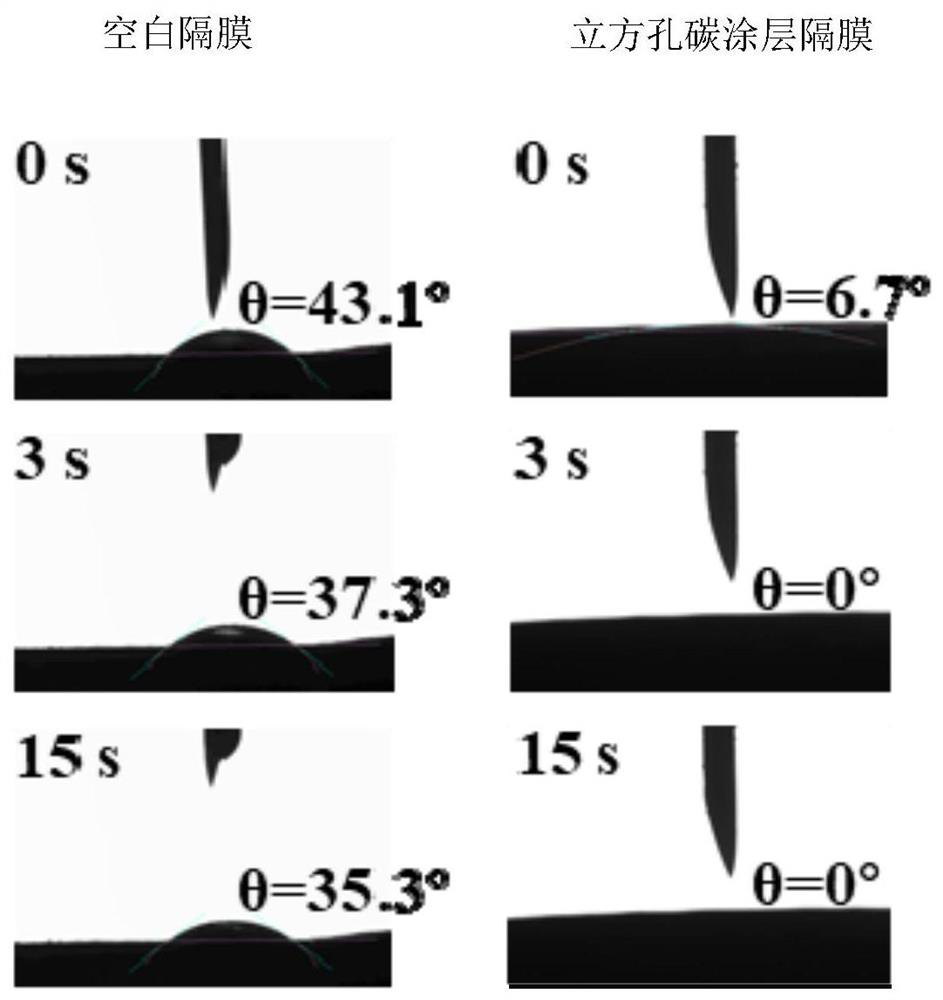

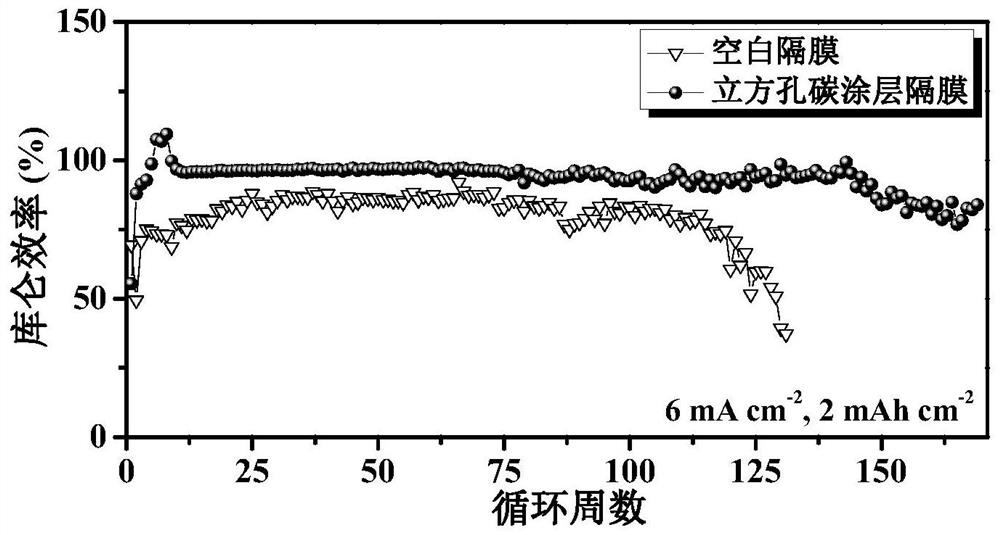

A lithium metal battery and cubic technology, applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., to achieve the effects of green and environmentally friendly large-scale production, improve lithium ion migration ability, and reduce interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Dissolve 1.1536g of ferric chloride and 0.4474g of manganese chloride in a small amount (5mL) of deionized water, add 20g of sodium oleate and mix well, heat to 80°C, keep warm for 3h and cool to room temperature to obtain template and precursor body mixture;

[0059] (2) Add powdered sodium sulfate 40g to the mixture obtained in step (1), and fully mix to obtain pre-carbonized material;

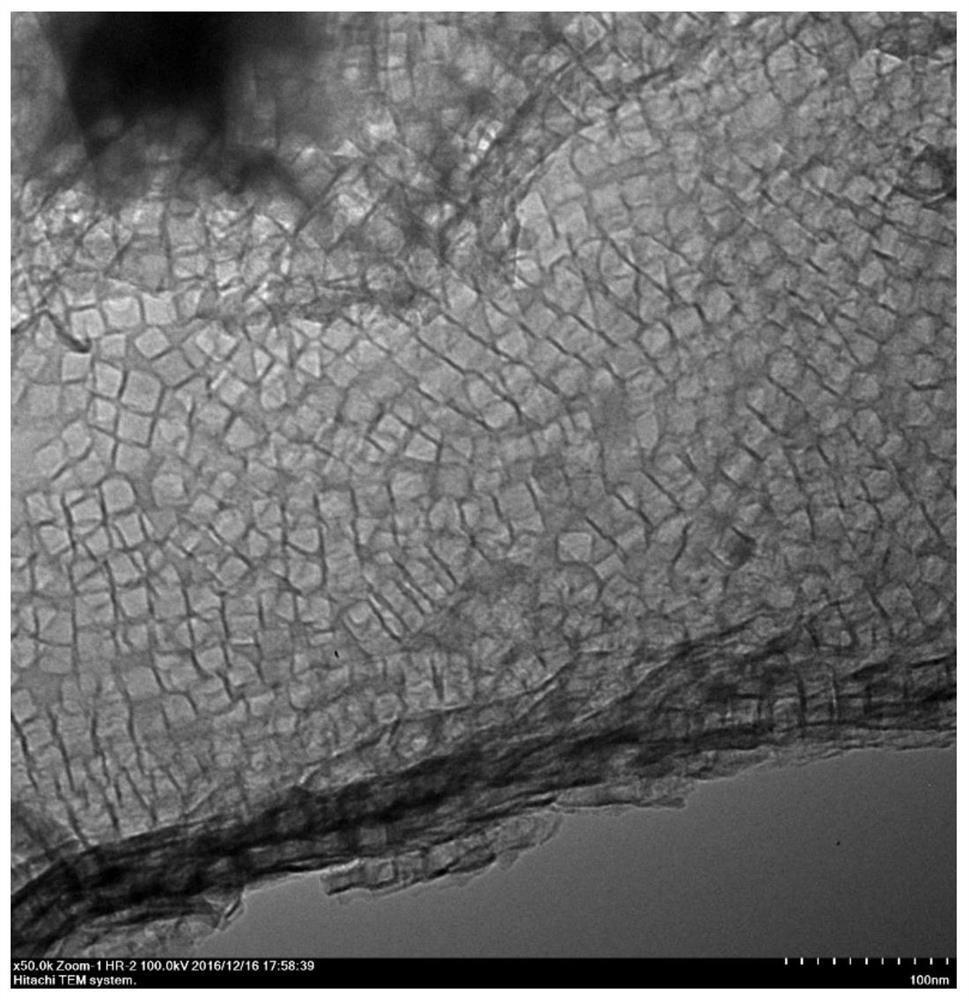

[0060] (3) Heating the pre-carbonized material to 700°C at a heating rate of 5°C / min in a nitrogen atmosphere, keeping it warm for 4 hours, and then cooling to obtain a cubic-pore carbon material with an inorganic salt template inside;

[0061] (4) Place the cubic-pore carbon material with the inorganic salt template in dilute hydrochloric acid for 6 hours to remove the template, and wash and dry (dry at 100° C. for 24 hours) to obtain a pure cubic-pore carbon material;

[0062] (5) Heating the cubic-pore carbon material to 800° C. at a heating rate of 5° C. / min in a nitrogen atm...

Embodiment 2

[0068] (1) Dissolve 1.1536g of ferric chloride and 0.4474g of manganese chloride in a small amount (5mL) of deionized water, add 10g of sodium oleate and mix well, heat to 80°C, keep warm for 3h and cool to room temperature to obtain template and precursor body mixture;

[0069] (2) Add powdered sodium sulfate 40g to the mixture obtained in step (1), and fully mix to obtain pre-carbonized material;

[0070] (3) Heating the pre-carbonized material to 500°C at a heating rate of 5°C / min in a nitrogen atmosphere, keeping it warm for 4 hours, and then cooling to obtain a cubic-pore carbon material with an inorganic salt template inside;

[0071] (4) Place the cubic-pore carbon material with the inorganic salt template in dilute hydrochloric acid for 6 hours to remove the template, and wash and dry (dry at 100° C. for 24 hours) to obtain a pure cubic-pore carbon material;

[0072] (5) Heating the cubic-pore carbon material to 800° C. at a heating rate of 5° C. / min in a nitrogen atm...

Embodiment 3

[0078] (1) Dissolve 1.1536g of ferric chloride and 0.4474g of manganese chloride in a small amount (5mL) of deionized water, add 7.2g of sodium gluconate and mix well, heat to 80°C, keep warm for 3h and cool to room temperature to obtain the template and a mixture of precursors;

[0079] (2) Add powdered sodium sulfate 80g to the mixture obtained in step (1), and fully mix to obtain pre-carbonized material;

[0080] (3) Heating the pre-carbonized material to 700°C at a heating rate of 5°C / min in a nitrogen atmosphere, keeping it warm for 4 hours, and then cooling to obtain a cubic-pore carbon material with an inorganic salt template inside;

[0081] (4) Place the cubic-pore carbon material with the inorganic salt template in dilute hydrochloric acid for 6 hours to remove the template, and wash and dry (dry at 100° C. for 24 hours) to obtain a pure cubic-pore carbon material;

[0082] (5) Heating the cubic-pore carbon material to 900°C at a heating rate of 5°C / min in a nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com